cedar shake & shingle

Roofing: MATERIALS ENCYcLOPEDIA

Applications for this system

Roof sheathing for roofs with a minimum pitch of 3:12 or 4:12

Siding

Basic materials

Cedar shakes or shingles

Strapping

Nails

Underlayment may be required in some installations

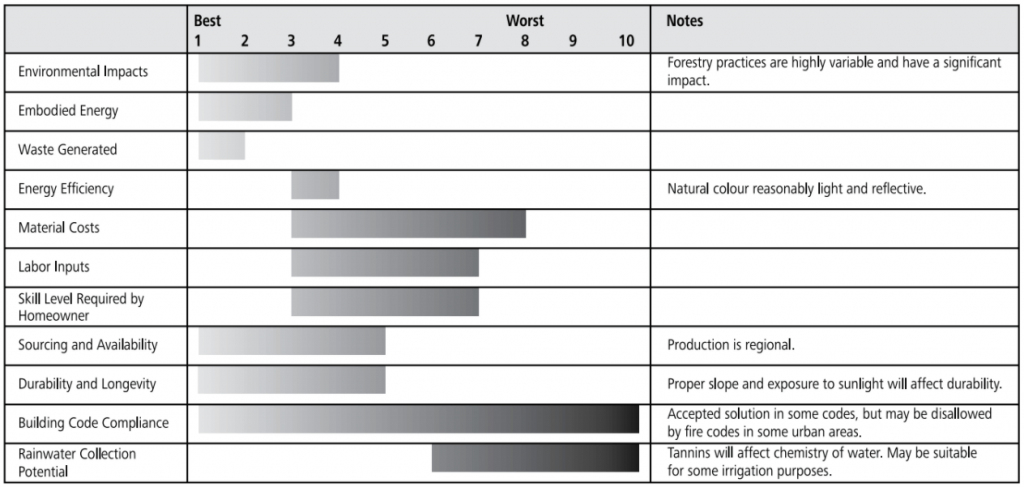

Ratings Chart for Cedar Shake/Shingle

The ratings chart shows comparative performance in each criteria category. Click on the tabs below for detailed analysis of each criteria.

- HOW THE SYSTEM WORKS

- ENVIRONMENTAL IMPACTS

- WASTE

- EMBODIED CARBON

- ENERGY EFFICIENCY

- MATERIAL COSTS

- LABOUR INPUT

- SKILL LEVEL REQUIRED

- SOURCING & AVAILABILITY

- DURABILITY

- CODE COMPLIANCE

- RAINWATER COLLECTION CAPABILITY

- RESOURCES

- FUTURE DEVELOPMENT

cedar shake and shingle System

The terms “shake” and “shingle” refer to how the roofing is made from the original cedar log. Shingles are milled (saw cut) from the log, while shakes are split from the log. Shingles are much more common in this era. Most of the products called shakes today are saw-milled, but done so at varying thicknesses to reproduce the more random thicknesses associated with old hand-split shakes. The more “authentic” modern shakes are textured on one side to further replicate a hand-split appearance.

Regardless of whether shakes or shingles are used, the system for installation is the same, and is similar to any shingle-style product. Horizontal courses of shingles are laid side by side (with a small gap to allow for expansion when wet), with the next course laid over top of the preceding one such that a set amount of the lower course is left exposed. The seams between shingles are offset between courses, and the “reveal” exposed on each course is such that a cross section of the roof would show three layers of shingle at any point in the roof. The shingles come in varying widths, making it easy to stagger the joints between courses.

Shingles can be installed in even courses or staggered slightly to create a variegated pattern at each course. Sometimes shingles are cut into patterns on the exposed edge, creating patterns across a single course or over multiple courses.

Older cedar shingle installations were fastened to roof strapping laid at centers that corresponded to the length of the shingles and the desired reveal. This allowed for air circulation behind the shingles, which aided in helping them dry out between rainfalls. The move to solid plywood decking in the 1950s resulted in shorter lifespans for cedar shingles, as water would remain trapped between the shingles and plywood, where they were in constant contact. The same issue can arise when products like tar paper or other membranes are placed directly behind the shingles.

Today, strapping is often added on top of plywood decking to provide ventilation, or plastic mesh products are used to create airspace between plywood and shingles. However, the old style of installation over simple strapping works very well, as it minimizes material use, costs and labor time.

Shingles are overlapped to create ridge and hip caps and metal flashings are typically used in valleys, with the shingles cut to leave the flashing exposed.

Cedar shingles are a unique roofing material in that they actually absorb a large amount of the water that strikes them and then release this moisture to the air after the rainfall. They swell as they absorb water and if properly spaced, the gaps between them will close.

Cedar shingles are often made from western red cedar and exported across the continent. However, eastern white cedar can be used to make long-lasting shingles, reducing shipping for the eastern half of the continent.

Environmental Impact Rating

Harvesting — Negligible to High

A cedar log cut locally and wisely and split into shake by hand will have dramatically lower impacts than a cedar log that is clear-cut from sensitive ecosystems far away from the building site. The use of FSC or other third-party certified wood will go a long way to ensuring minimal impacts.

Manufacturing — Negligible to Moderate

The processing of cedar logs into shingles is not particularly energy intensive and is often done at local, small-scale mills.

Chemical treatments may be applied to shingles, including trisodium phosphate, bleach, zinc or copper sulfate, zinc chloride and proprietary biocides. To minimize the air- and water-borne impacts of these chemicals during manufacturing and application, specify shingles that are not treated.

The balance of the roofing system will also affect impacts. Simple strapping over roof framing will have the lowest manufacturing impacts (especially if local and/or third-party certified wood is used). Solid plywood decking with a plastic breather product and/or waterproofing membrane will raise the impacts significantly. Determining all the components of the system is important in assessing the choice of cedar as a roofing material, especially when introducing petrochemicals to an otherwise natural system.

Transportation — Negligible to Moderate

0.71 MJ per km by 15 ton truck

0.45 MJ per km by 35 ton truck

0.12 MJ per km by rail

Distance from point of harvest to point of manufacture to final building site can vary from nothing to cross-continent truck journeys. Sourcing locally lowers impacts significantly.

Installation — Negligible to Low

Putting cedar shingles on a roof is a low-intensity job which can be completed entirely with hand tools with very little penalty in labor input. Shingles are light to move onto the roof and can be cut with a sharp blade and nailed into place, eliminating or minimizing power tool use.

Waste: Negligible to Low

Compostable — All cedar and strapping offcuts. Quantities will vary from negligible to moderate, depending on the complexity of the roof.

Recycleable — Metal fasteners. Quantities will be negligible.

Landfill — Plywood offcuts, membrane or underlayment offcuts, caulking tubes. Quantities will be low.

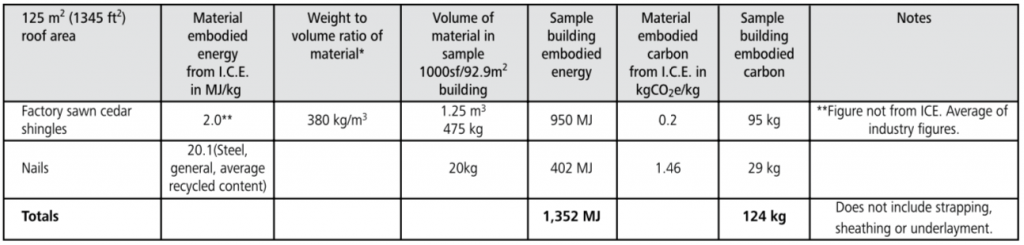

Chart of Embodied energy & carbon

Energy Efficiency: Very Low

The use of cedar shingle roofing will have little impact on the overall energy efficiency of the building. The reflectivity of cedar shingles is better than even the lightest-colored asphalt shingles, though less than white roofs of other materials*.

*Laboratory Testing of the Reflectance

Properties of Roofing Materials

D.S. Parker

J.E.R. McIlvaine

S.F. Barkaszi

D.J. Beal

M.T. Anello

Florida Solar Energy Center (FSEC), FSEC-CR-670-00

Reagan and Acklam (1979) measured the solar reflectance of new unoiled and unpainted cedar shake wood shingles at 32%. Oiled shakes had a total solar reflectance of 28%.

Material costs: moderate to high

Areas where cedar is a common roofing option will have lower costs.

Labour Input: moderate to High

A cedar shingle roof is relatively labor intensive to install. If strapping is being used, it will be on much closer centers (typically 5–8 inch / 12–20 cm OC) than required for other sheathings, increasing installation time. Using solid decking and/or underlayment or waterproofing membranes will also increase installation time.

The laying of the shingles is fairly straightforward and comparable to other styles of shingles except that the cedar will come in a variety of widths that must be selected for each space, and each shingle should be inspected for imperfections before being installed.

Ridge and hip caps are time-consuming to install, as the overlapping must be done carefully to ensure a long, leak-free lifespan.

Health warning

Working at heights to install roofing has inherent dangers. Proper setup and safety precautions should always be taken when working on a roof.

Skill level required for homeowners

Decking — Easy

Homeowners possessing the carpentry skills to create the roof structure will have no difficulty decking the roof for cedar shingles.

Underlayment (if required) — Easy

Underlayment materials are lightweight and typically come in rolls that are straightforward to place.

Shingles — Easy

The basic laying of shingles is quite straightforward and beginners should be able to follow instruction manuals for a successful installation. A solo builder or a small crew can lay cedar shingles, albeit at a slower pace. Adding cut patterns to a roof requires careful planning and pre-cutting of shingles, but is not overly difficult to execute.

Caps and Flashing —Moderate to Difficult

Capping and flashing details can also be learned from manuals, but may be better understood by examining existing roofs or consulting with a professional. Metal ridge and hip flashing can be used over cedar shingles if a beginner is uncertain about installing these elements of the roof in cedar.

Sourcing & availability: Easy to moderate

As both western red cedar and eastern white are viable options, any builder in a region where these trees exist should be able to source quality shingles. Western red cedar is exported across the continent, though it may be a special order item in some regions.

Durability: moderate to High

Properly installed with adequate ventilation below the shingles, a proper pitch and adequate drying potential, a cedar shingle roof can have a lifespan of thirty to forty years. Assess the lifespan of existing cedar shingle roofs in your region, as climate will have a definite impact on longevity.

Code compliance

Cedar shingle roofs have a long history in North America, but are not always directly recognized in modern building codes. Many code jurisdictions accept cedar shingle roofs based on technical documents from lumber groups and manufacturers, and these will often mandate the use of a synthetic breather layer, plywood decking and a membrane product. Those wishing to use the simpler, low-impact method of shingles over strapping may have to work harder to convince code officials of the viability.

Some urban areas will not allow cedar shingle roofs due to concerns about fire, so be sure to check fire codes as well as building codes before choosing a cedar shingle roof.

RAINWATER COLLECTION CAPABILITY: LOW

Water caught from a cedar shingle roof will be heavily loaded with cedar tannins and oils that will render the rainwater harvested unfit for potable uses and potentially problematic for irrigation purposes. Treated shingles will also leach embedded chemicals into the water.

Resources for further research

Cedar Shake and Shingle Bureau, New Roof Construction Manual, cedarbureau.org/cms-assets/documents/30985-306719.roof-manual-011.pdf

Red Cedar Shingle and Shake Design and Application Manual for New Roof Construction. Bellevue, WA: Red Cedar Shingle and Handsplit Shake Bureau, 1990. Print.

Harrison, H. W. BRE Building Elements: Roofs and Roofing: Performance, Diagnosis, Maintenance, Repair and the Avoidance of Defects. London: Construction Research Communications, 2000. Print.

Roofing: The Best of Fine Homebuilding. Newtown, CT: Taunton, 1996. Print.

Scharff, Robert, and Terry Kennedy. Roofing Handbook. New York: McGraw-Hill, 2001. Print.

Future development

It is unlikely that the method of producing or installing cedar will undergo much change. The availability and cost of cedar will fluctuate based on supply and demand. The wider use of third-party certification for harvesting cedar will likely have a positive impact over time.

Tips for A successful CEDAR SHAKE AND SHINGLE ROOF

1. Whether using simple strapping or a synthetic breather layer, ensure that shingles have an air space behind them. Attaching shingles directly to a solid decking will dramatically reduce lifespan. The type of decking and/or spacer used will affect costs, installation time and environmental impact, so be sure to consider the roofing as a whole system.

2. Shingles can be prone to splitting when being nailed in place. Using the proper-sized nail or staple is critical. Any split shingle should be removed, or treated as two shingles each with its own fastener.

3. Don’t overtighten the fasteners. Drive each fastener deep enough that its head makes only light contact with the surface of the shingle, to prevent splitting when the shingle swells when wet.

4. The first course of shingle is a double course to provide the “three-thick” shingle profile at the edge of the roof. Many installers place the first layer “upside down,” with the thicker end pointing up the roof to prevent the double layer from changing the pitch at the end of the roof. Overlapping seams between the doubled first courses is important.

5. The location of a cedar shingle roof will have an impact on its lifespan. Cedar roofs do best when they can go through complete drying cycles between wettings, so cedar roofs in highly shaded areas will often sprout moss and deteriorate at an accelerated rate.

6. Do not put cedar shingles at too shallow a pitch. This type of roofing requires the assistance of gravity to prevent water from making its way underneath the courses and causing leaks. Systems with solid underlayment and/or membranes will specify a minimum 3:12 pitch, while the minimum for shingles over strapping is 4:12.

7. Shingle suppliers may offer as many as four grades of shingle. Only A-grade shingles with no imperfections should be used for roofing. High-quality B-grade may be suitable for steeper pitches. C- or D-grade should not be used.

8. Some shingle suppliers will chemically treat shingles to extend lifespan or maintain appearance. Many of these treatments involve toxic chemicals, and should be well researched before purchasing.