Timber frame/Post & Beam

Floor & Roof Structure: MATERIALS ENCYcLOPEDIA

Applications for this system

Floor and roof framing

Basic materials

Large timbers

Metal bracketry and fasteners for post and beam

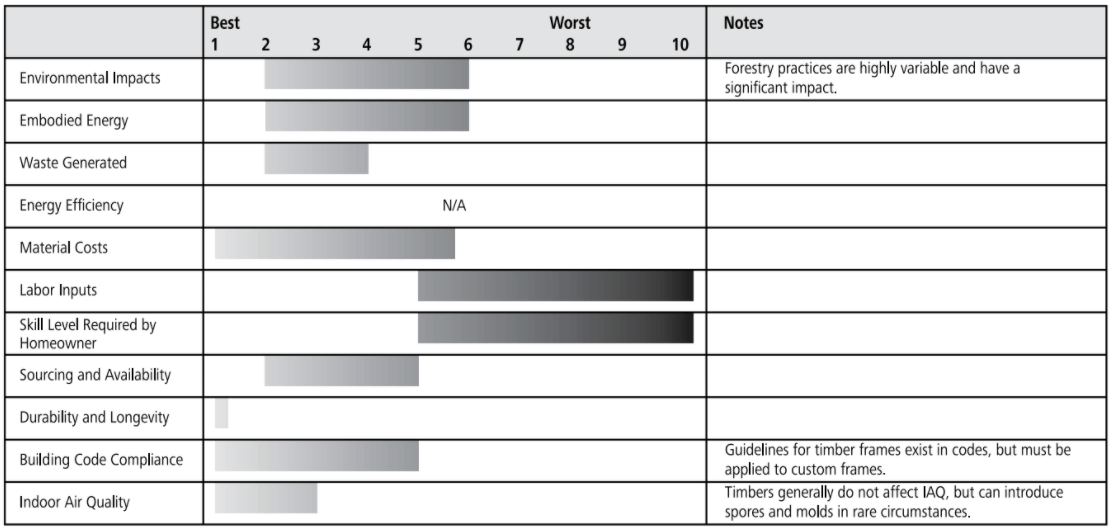

Ratings Chart for Timber frame

The ratings chart shows comparative performance in each criteria category. Click on the tabs below for detailed analysis of each criteria.

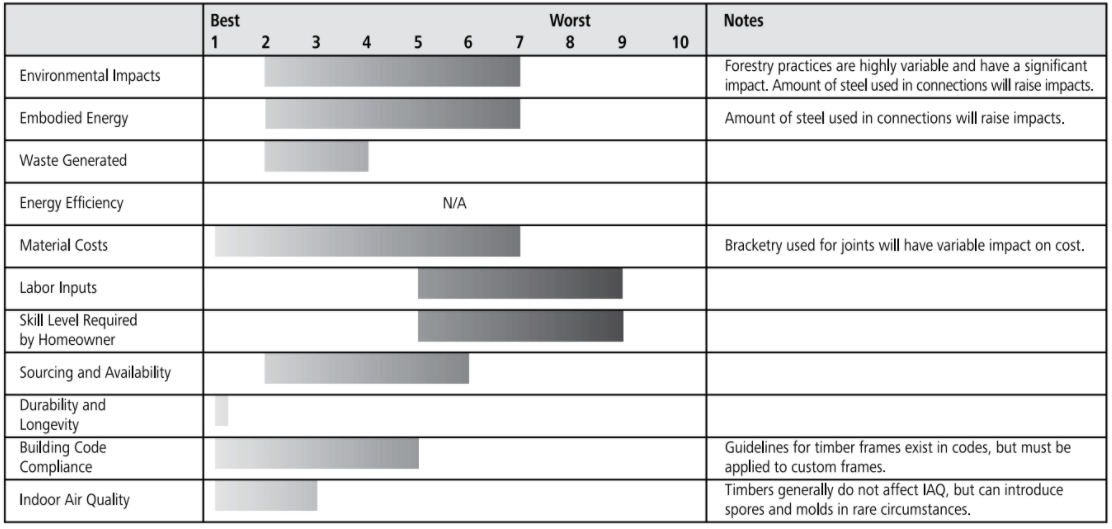

Ratings Chart for Post and beam

The ratings chart shows comparative performance in each criteria category. Click on the tabs below for detailed analysis of each criteria.

- HOW THE SYSTEM WORKS

- ENVIRONMENTAL IMPACTS

- WASTE

- EMBODIED CARBON

- ENERGY EFFICIENCY

- MATERIAL COSTS

- LABOUR INPUT

- SKILL LEVEL REQUIRED

- SOURCING & AVAILABILITY

- DURABILITY

- CODE COMPLIANCE

- INDOOR AIR QUALITY

- RESOURCES

- FUTURE DEVELOPMENT

Timber frame/post and beam System

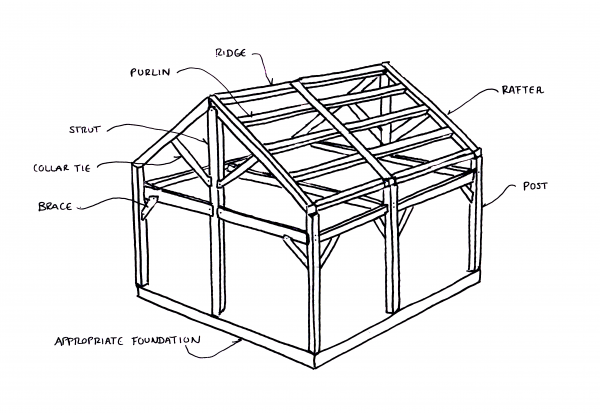

Solid timbers of large dimensions (usually 8×8 or greater) are used to create a floor joist system and/or a roof truss system. The spacing of the joists or roof members is determined by the size of the timber and the expected loads.

Solid timbers of large dimensions (usually 8×8 or greater) are used to create a floor joist system and/or a roof truss system. The spacing of the joists or roof members is determined by the size of the timber and the expected loads.

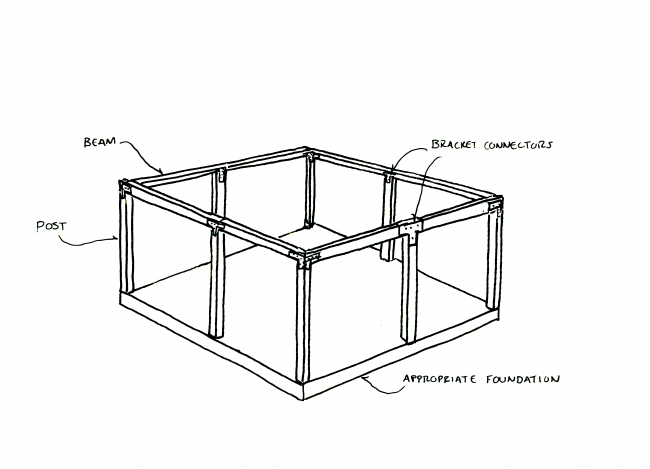

Traditional timber framing uses wood-to-wood joinery between timbers, typically including the use of wooden pegs to fasten joints. Post and beam systems will use metal bracketry and fasteners to connect members. These metal fasteners can be standard, off-the-shelf materials or can be custom-welded to achieve particular structural and/or aesthetic goals.

Environmental Impact Rating

Harvesting — Negligible to High

Wood harvested from the building site or the local region can have negligible impacts. Unmanaged forestry can have impacts that include significant habitat destruction, soil erosion and ground water contamination. Third-party certification can help to ensure that impacts are minimized.

Metal fasteners and bracketry may be a significant component. Ore for steel production is mined in an intensive process with impacts including habitat destruction and soil and water contamination.

Manufacturing — Negligible to Moderate

The sawing and planing of structural lumber is a relatively low–impact mechanical process.

Processing raw ore into nails and screws is a multi-stage and intensive process requiring multiple infusions of high heat and fossil fuel use with impacts including air and water pollution.

Transportation — Negligible to High

Sample timber frame building uses 3,222 kg of timber for wall and roof framing:

4.8 MJ per km by 15 ton truck

3 MJ per km by 35 ton truck

Sample post and beam building uses 1,575 kg of timber for wall framing:

2.35 MJ per km by 15 ton truck

1.5 MJ per km by 35 ton truck

Timber is a heavy and high-volume material and accrues significant impacts proportional to distance traveled. In most regions it is possible to source lumber a reasonable distance from the building site.

Installation — Negligible to Moderate

The number of offcuts from a timber or post and beam frame can be quite high. Careful cut lists and ordering can minimize this waste.

Waste: moderate

Compostable – All wood-offcuts

Recyclable – Metal fasteners

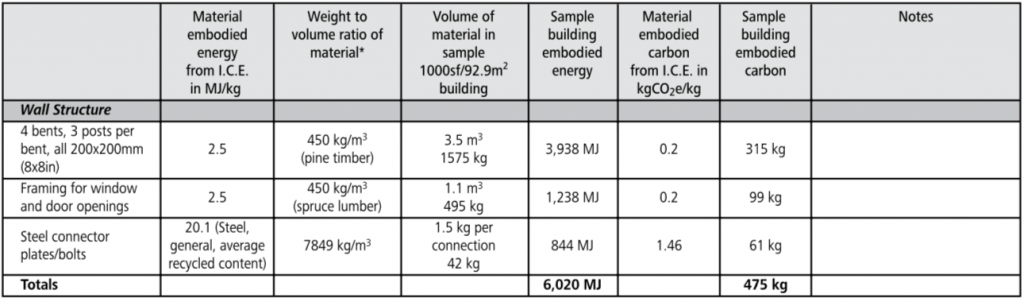

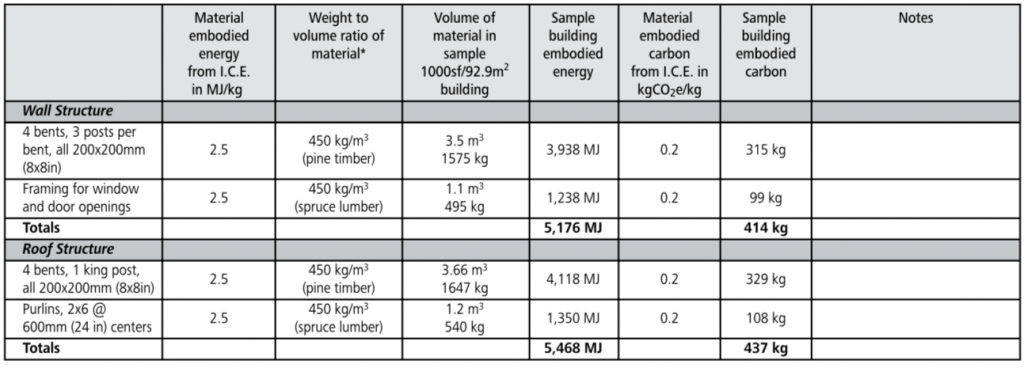

Chart of Embodied energy & carbon

post and beam:

Timber frame:

Energy Efficiency

Timbers are typically used in scenarios where the beams/joists are exposed, so any insulation strategy is usually accomplished on the outside of the timbers. Careful attention must be paid to keeping the insulation continuous at the roof/wall junction to prevent cold bridges or lesser levels of insulation that will negatively impact thermal performance. As long as the exterior insulation levels are suitable and the roof/wall junction detailed appropriately, the timber framing won’t have any impact on energy efficiency.

Material costs: Low to moderate

Timbers can be purchased for a cost that is typically less than for a similar quantity of milled framing lumber, depending on species, dimensions, quality and transportation distance.

The steel connectors for post and beam framing can be quite costly unless it is standard, off-the-shelf connectors. Research is required to accurately cost this element of the frame.

Labour Input: moderate to High

Timber structures have significantly fewer members than stick frame structures, which can lower the amount of labor input. The biggest impact on labor input will be the complexity of the joinery and the time required to complete each joint. This is an issue that can be addressed at the design stage, with joinery specified to meet specific labor requirements.

The metal bracketry of post and beam designs is often chosen to reduce the labor input required to cut traditional joints. However, the reality does not always meet that expectation. Be sure that any bracketry included in the design will indeed save time (and money) on-site. If timbers need to be trimmed or have slots, notches or pre-drilled holes added to fit inside brackets the process could take as much labor time as making timber frame joints.

The method of moving heavy timbers will also impact labor time. Using large work crews to hoist timbers adds more labor hours than using equipment or machinery.

Skill level required for homeowners: moderate to high

Traditional timber framing is a highly skilled profession, and it can take many years of experience to cut and assemble a top-notch frame. However, the principles of joining large timbers are quite straightforward, and many beginners will be able to cut and assemble frames that are structurally functional but may lack the refinement and high degree of fit and finish of professionally built frames.

Those with less wood working skills can typically complete post and beam work, as long as the bracketry and fastening system is straightforward. Custom-made bracketry can require welding skills or may need to be hired out.

Sourcing & availability: moderate to Difficult

Many regions will have sources of locally and sustainably harvested timbers. If you live in a region without a source of large-diameter timbers, be sure to consider the transportation distances and forestry impacts at the source.

Recycled timbers are relatively common from disassembled barns, homes and factory buildings. If you choose to work with them, it is best to source the timbers first and then base a design around them, as it can be difficult to source recycled timbers to meet predetermined size requirements.

Steel connectors for timber structures will likely need to be special-ordered or custom made.

Specialty tools for timber framing will also need to be sourced.

Durability: High to Very High

Timber structures have centuries of proven durability. Kept relatively dry and free from damaging insects, a timber frame makes a remarkably durable and adaptable structure.

Code compliance

The long and established history of timber framing makes it a widely acceptable solution familiar to code officials in most jurisdictions. However, most codes do not include specific design standards for timber frames and will require frames to be designed by a structural engineer or other accepted professional

Indoor air quality

Typically, timber frames will not have a negative impact on IAQ. However, they can be built with a wide variety of wood species, and certain fragrant species may cause reactions for certain occupants.

Recycled timbers should be inspected for potential contamination from their previous use, especially when sourced from factories and barns.

Resources for further research

Roy, Robert L. Timber Framing for the Rest of Us. Gabriola Island, BC: New Society, 2004. Print.

Bensen, Tedd. The Timber-Frame Home. London: Taunton, 1997. Print.

Sobon, Jack, and Roger Schroeder. Timber Frame Construction: All about Post and Beam Building. Pownal, VT: Storey, 1984. Print.

Stirling, Charles. Timber Frame Construction: An Introduction. Garston, UK: BREhop, 2004. Print.

Chappell, Steve. A Timber Framer’s Workshop: Joinery, Design and Construction of Traditional Timber Frames. Brownfield, ME: Fox Maple, 1998. Print.

Bingham, Wayne J., and Jerod Pfeffer. Natural Timber Frame Homes: Building with Wood, Stone, Clay, and Straw. Salt Lake City, UT: Gibbs Smith, 2007. Print.

Beaudry, Michael. Crafting Frames of Timber. Montville, ME: Mud Pond Hewing and Framing, 2009. Print.

Law, Ben, and Lloyd Kahn. Roundwood Timber Framing: Building Naturally Using Local Resources. East Meon, UK: Permanent Publications, 2010. Print.

Future development

Timber framing has been used for centuries, and it is unlikely that new developments will significantly alter the materials or approach. Dwindling stocks of large-diameter trees make it unlikely that timber framing will ever be a widespread, mainstream solution, but existing commercial and private forests will be able to supply the specialty market for a long time to come.

Tips for a successful timber frame or post and beam floor or roof

1. Large timber structures will typically need to be designed by a professional engineer or a recognized timber designer. Be sure that your designer is able to provide a quality design using all appropriate code guidelines and requirements.

2. Every species of tree has different strength and workability characteristics and appearance, and a timber frame-builder must ensure that the wood used is appropriate for the type of construction chosen.

3. The interface between timber frames and wall and roof enclosures and sheathing must be detailed appropriately to ensure energy efficiency and durability. Cold bridges and proper air sealing are critical considerations at the design and construction phases.

4. Large timbers are heavy and may require special lifting apparatus to install. Whether it is scaffolding and people power, ropes and rigging or cranes, it is important to plan for the lifting of timbers.

5. Timbers can be milled and planed to different degrees of finish, or may be left with a raw wood finish or have a finish applied after installation. Be sure you know what type of finish you want your timbers to have from the outset.

6. The spacing of large timber members is wider than with stick lumber, so the flooring and roof decking must be chosen to suit these wider spacings. Typical plywood subflooring and roof decking is unlikely to be adequate without additional support, and flooring and sheathing are usually visible and part of the overall aesthetic of the building, making these choices an important part of the structural and aesthetic considerations at the design stage.