Ground-source Heat pump

HVAC: MATERIALS ENCYCLOPEDIA

Heat production & delivery

Heat pump production

Air or hydronic delivery

Can be used for domestic hot water heating

System components

Ground loops (buried horizontally in deep trenches or vertically in drilled wells) and circulation pump

Heat pump unit with compressor

Air or hydronic delivery system

Controls as required

How the system works

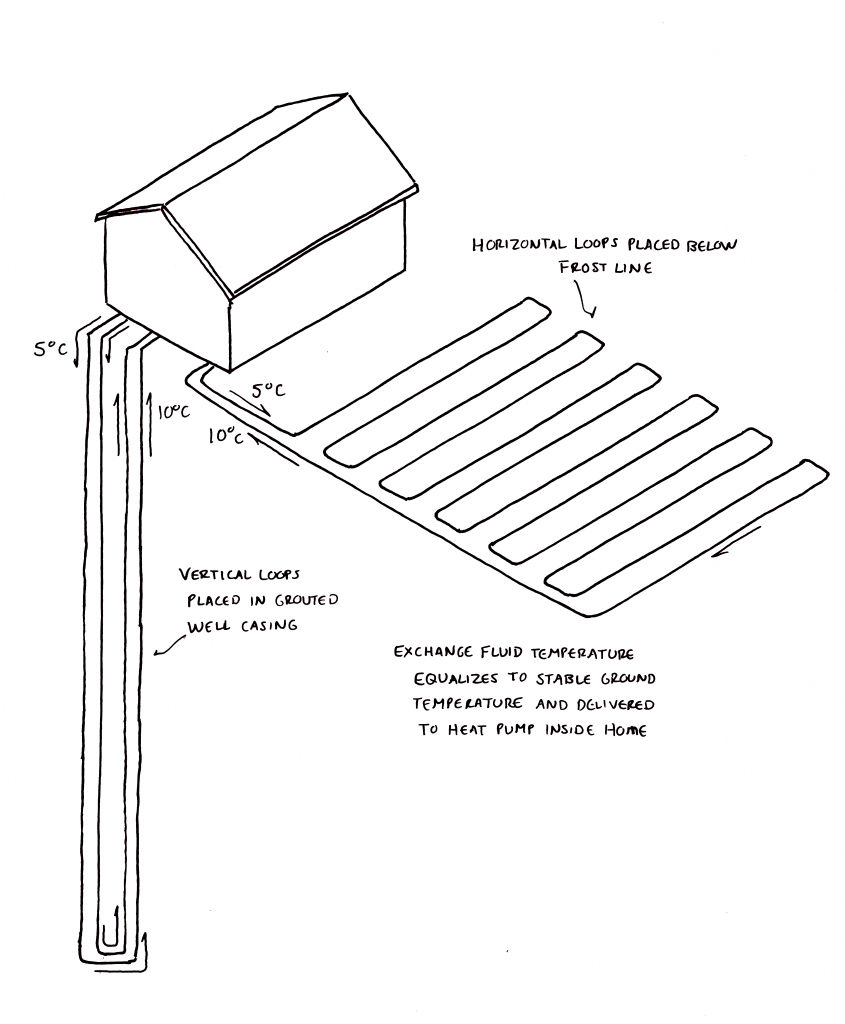

There are two basic arrangements for GSHPs:

Horizontal Ground Loop — The collection loop for the heat pump is placed in trenches dug to a depth below the frost line. Horizontal loops can also be submerged in bodies of water below the expected ice depth.

Vertical Ground Loop — The collection loop for the heat pump is placed in one or more vertically drilled wells that are capped and grouted to protect ground water.

The ground loops collect or disperse heat (depending on whether the GSHP is in heating or cooling mode) in the ground. The length of the tubes is designed to ensure that the fluid in the pipes has enough contact time with the ground that input temperatures will be constant. The more Btus required of the system, the longer the ground loops. These can be closed loops that circulate a heat exchange fluid, direct exchange loops in which refrigerant from the heat pump is sent through the ground loop or, more rarely, open loops that draw ground water in and then discharge it in a different well or location in a body of surface water.

Fluid from the ground loops imparts its temperature to the refrigerant on one side of the heat pump, and the compressor puts the refrigerant through the heat pump cycle to either create or extract heat for the home.

The output side of the heat pump has a heat exchanger that transfers temperature to an air or hydronic delivery system, as required by the home’s thermostat.

System output

Independent testing of ground source heat pump units by Natural Resources Canada showed output for a wide array of residential units ranged from 8.7 to 12.8 Btu/hr/watt, or a coefficient of performance (COP) of 2.6 to 3.8.

When considering COP figures for heat pumps, it is important to note that the electrical energy required to run the pump is often excluded, making the figures look much more positive than the reality in use.

In North America, GSHPs are often rated by “tons” of output. A ton is 12,000 Btu/hr, and residential units typically range from 0.75–5 tons (9,000 – 60,000 Btu/hour) of output

Environmental impacts: moderate to high

There are benefits to the efficiencies enjoyed by GSHPs, reducing overall energy use and emissions. If the electrical energy is supplied by renewable sources, the systems can be emission free.

The refrigerants used in the heat pumps are significant greenhouse gasses, with impacts much higher (as much as a hundred times) than that of CO2. The most dangerous refrigerants have been or are in the process of being phased out, but the current compounds still have significant impacts during manufacturing, commissioning, repairs and if or when leaks occur in the system. Currently, refrigerants like R-410A are touted as being environmentally friendly, but only compared to the extremely unfriendly versions they replace.

Digging of ground loop trenches is highly disruptive to the immediate ecosystem, and drilling wells can affect ground water.

Material costs: very high

Labor input: high

The installation has several distinct phases, all of which require a lot of labor.

Skill level required for the homeowner

Installation — Difficult. Only licensed installers can perform a GSHP installation, due to the need to charge the system with refrigerant.

Use — Easy.

Maintenance — Moderate to Difficult. Leaks in any part of the system can be very hard to trace and repair. Professionals must address issues with the hardworking compressor pump or any aspect of the system that requires charging/discharging of refrigerant.

Sourcing/availability: Easy to moderate

There are sufficient numbers of GSHP designers, suppliers and installers that competitive quotes should be available in most regions.

Code compliance

GSHPs are an accepted solution in many codes. If not directly recognized, a properly designed system should be accepted as an alternative solution.

Durability: moderate

Residential GSHPs are relative newcomers to the market that have not proven themselves over decades, but are anticipated to have a life expectancy of fifteen to twenty years. Manufacturers will offer warranties of five to ten years on compressors.

Indoor air quality

A GSHP will not have any direct effect on IAQ, except in the rare case of a refrigerant leak.

Hydronic delivery systems result in gentle air movement and minimal circulation of dust and allergens.

Forced-air delivery systems can circulate a lot of dust and allergens. Use the best filters possible to help reduce issues.

Adequate ventilation is required in any well-sealed home. Whether provided actively or passively, ensure that pre-warmed fresh air is introduced and circulated in the home during seasons when windows are closed.

Future development

Rapid and significant improvements have been made to GSHPs over the past decade, and while dramatic changes are unlikely there will be continued gains in efficiency and lowering of costs. The most important development from an environmental perspective would be a move to more benign refrigerants. CO2 is being used as a refrigerant in some new units, and other natural compounds are being researched. All natural refrigerants require design changes to heat pumps that currently raise electrical demand and have durability issues, but growing pressure to phase out all damaging refrigerants will likely lead to positive developments.

Resilience

There is no way to build, install or operate a GSHP in a low- or no-energy scenario.

Tips for a successful ground source heat pump

1. A GSHP must be designed based on an accurate heat loss calculation. If they are too large or too small, the units will operate outside of their most efficient range and performance can be disappointing.

2. Excavation for horizontal loops can be very destructive to the building site. Assess the site’s ecosystem and ensure that the digging will not cause irreparable harm.

3. The heat pump unit can be very loud. Be sure to separate it from the living space to sufficiently muffle the sound.

4. Some models of GSHP can help to heat domestic hot water, a cost-efficient option.

5. Output temperatures of GSHPs are lower than those of combustion devices. Heat delivery systems must be quite efficient to ensure delivered temperatures are high enough for comfort.