Stone

FOUNDATIONS: MATERIALS ENCYcLOPEDIA

Applications for this system

Perimeter Beams

Frost walls, including full basement walls

Piers

Basic materials

Stone. Can be available fieldstone, cut stone or rubble. Dry stone walls are best built with stone that has a flat profile

Mortar. Can be typical masonry cement or traditional lime mortars

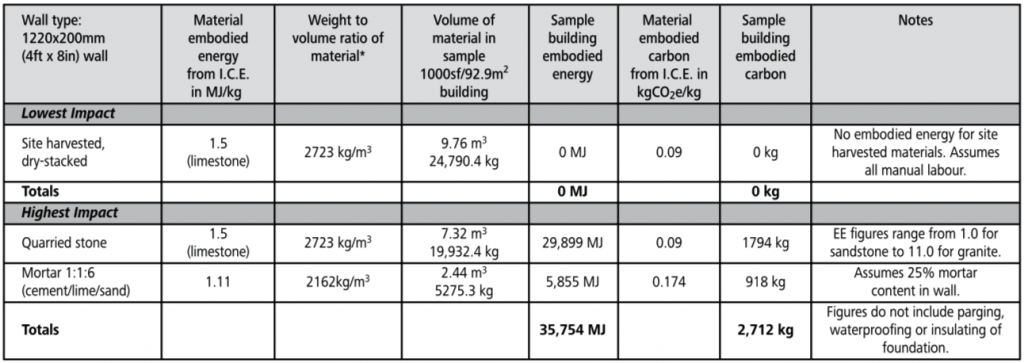

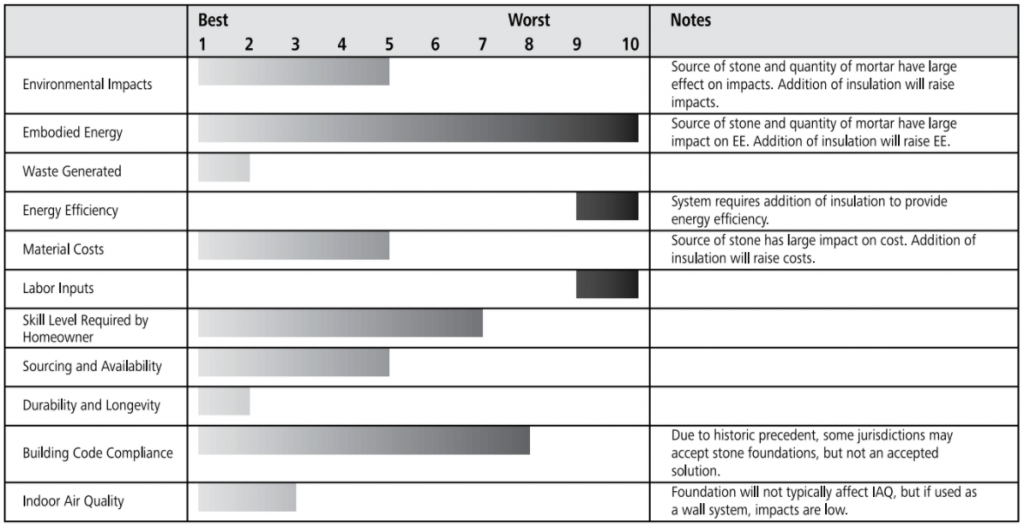

Ratings Chart for stone Foundation

The ratings chart shows comparative performance in each criteria category. Click on the tabs below for detailed analysis of each criteria.

- HOW THE SYSTEM WORKS

- ENVIRONMENTAL IMPACTS

- WASTE

- EMBODIED CARBON

- ENERGY EFFICIENCY

- MATERIAL COSTS

- LABOUR INPUT

- SKILL LEVEL REQUIRED

- SOURCING & AVAILABILITY

- DURABILITY

- CODE COMPLIANCE

- INDOOR AIR QUALITY

- RESOURCES

- FUTURE DEVELOPMENT

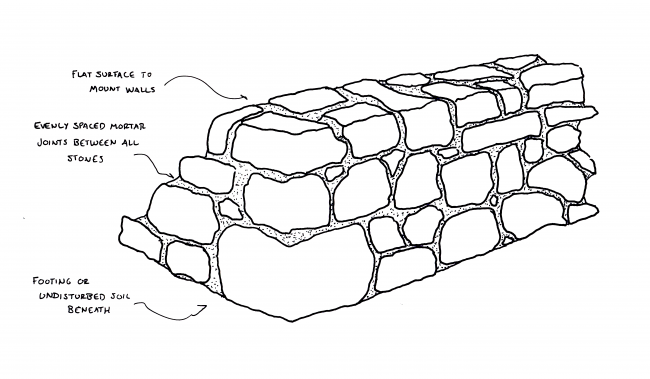

Mortared Stone Foundation

Stone is gathered to the building site and laid up by choosing stones of appropriate sizes to form courses and staggered joints between courses. Mortar is placed between courses and between the ends of each stone, so that each adjacent face of stone in the wall is embedded in mortar. A mortar cap typically provides a flat, level surface for the sill plates/walls.

Stone is gathered to the building site and laid up by choosing stones of appropriate sizes to form courses and staggered joints between courses. Mortar is placed between courses and between the ends of each stone, so that each adjacent face of stone in the wall is embedded in mortar. A mortar cap typically provides a flat, level surface for the sill plates/walls.

Mortared stone foundations can be used for perimeter beam, frost wall and basement style foundations, as well as piers. In basement scenarios, proper drainage and moisture protection must be used as water can penetrate mortar joints and pass into the building.

In cold climates where insulation strategies are required, mortared stone walls can be insulated from the interior and/or exterior sides, or they can be built as double wythe walls with insulation between the two walls.

There are three choices for mortar in a stone wall: lime, lime/cement or cement. Traditionally, lime mortars were used with stone. These mortars have a long, proven history in conjunction with natural stone. They are “softer” than mortars containing cement, which can allow the stones in the wall to shift slightly without damaging either stone or mortar. Lime mortar is also highly vapor-permeable, which can allow the wall to dry through the mortar joints. Lime mortars take a long time to harden and can limit the speed at which a wall can be laid up.

Lime/cement mortars are the most common modern choice. They retain some of the workability associated with lime mortars but have the advantage of the quick setting speeds of portland cement. Depending on the lime/cement ratio and the type of stone being used, these mortars can be harder than the stone itself and can lead to stress fractures in the stone rather than the mortar joint. They are somewhat less permeable, but not to a degree that is generally harmful to the wall.

Straight cement mortars are harder to work with and make mortar joints that are much harder than most stone. They are not permeable. Despite their quick setting times, they are not recommended for use in stone foundation walls.

Anchor bolts for walls in a mortared stone foundation can be embedded in the mortar joints between stones, making attachment of a wide range of wall types very straightforward.

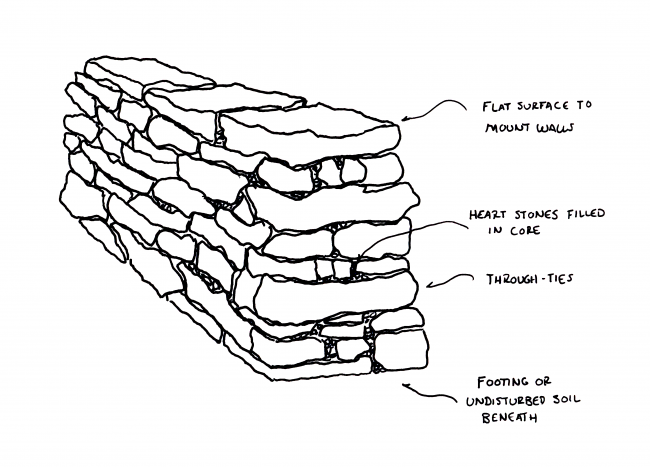

Dry-stacked foundations

Stone is gathered to the building site and laid up by choosing successive stones that fit together as tightly as possible. Foundation walls often use a row of larger stones on the inside and outside edge of the foundation. Between these two rows, smaller stones are used as heart-stones to pack and stabilize the spaces between the larger stones. With careful attention to hearting, the foundation walls will be very stable.

Stone is gathered to the building site and laid up by choosing successive stones that fit together as tightly as possible. Foundation walls often use a row of larger stones on the inside and outside edge of the foundation. Between these two rows, smaller stones are used as heart-stones to pack and stabilize the spaces between the larger stones. With careful attention to hearting, the foundation walls will be very stable.

Dry-stacked foundations challenge many basic modern assumptions about building. We tend to expect our buildings to be well glued together. However, dry stone advocates are quick to point out that there is an inherent strength in the basic stability and lifelong flexibility of this kind of foundation. Dry-stacked walls can handle a remarkable amount of shifting without giving up any structural strength. Lab testing has shown them to be sufficiently strong to handle moderate earthquake activity. History has shown them to be long-lasting, as they don’t tend to retain water so do not go through damaging freeze/thaw cycles like their mortared counterparts. Shifting due to frost heave or settlement under the foundation is likewise accommodated without any inherent damage to the stability of the wall.

Dry-stacked walls are suitable for perimeter beam or frost wall applications. Because they do not prevent water from migrating through the wall, they cannot be used as basement walls. Piers are possible with dry-stack stone, but need to be wide enough to offer proper stability.

Attaching walls to a dry stone foundation requires adaptation from standard practices. Some natural wall systems (cob, cordwood, straw bale) can be placed directly onto a dry stone foundation, but framed walls will need to be anchored to the stone in some way. This can be achieved by drilling anchors into the larger stones and/or using strapping that runs beneath the stone wall and over the sill plate of the framed wall.

Environmental Impact Rating:

Harvesting — Negligible to Moderate

Site-harvested stone has negligible impacts. Quarried stone is mechanically harvested and impacts can include habitat destruction and surface and groundwater contamination.

Mortar ingredients extracted from quarries mechanically can have low to high impacts on habitat destruction and ground and surface water contamination and flow.

Manufacturing — Negligible to High

Site-harvested stone has negligible to low impacts, depending on the amount and type of cutting/shaping required. Quarried stone is split and/or cut to the desired size and shape using low-impact mechanical equipment.

Mortar ingredients (lime and/or portland cement) are fired at extremely high temperatures and have high impacts including fossil fuel use, air and water pollution and greenhouse gas emissions.

Transportation — Negligible to High

Sample house uses 24,790 kg of bag material:

37.2 MJ per km by 15 ton truck

23.3 MJ per km by 35 ton truck

Heavy material, accrues significant impacts proportional to distance traveled.

Installation — Negligible

Waste: Negligible

Biodegradable/Compostable — All leftover stone can be left in the environment.

Landfill — Cement and/or lime bags

Chart of Embodied energy & carbon

Energy Efficiency: Very Low

A stone foundation has very little thermal resistance. In cold climates, stone foundations will need to be properly insulated in order to contribute to an energy-efficient building. Insulation strategies can vary depending on the style of foundation, the climate and the builder’s choices for insulation in adjacent components of the building (see sketches of four styles of stone foundations: 4-foot frost wall with insulated slab, 2-ft perimeter beam with skirt, double wythe with internal insulation, basement). As long as the building design has accounted for potential heat loss through the earthbag foundation and includes a sufficient insulation strategy, this style of foundation can be part of a well-designed, thermally appropriate structure in a wide range of climates.

Material costs: Negligable to moderate

Labour Input: Very High

Stone is heavy. A foundation requires a lot of stone. Adding these two factors together results in high labor inputs. The more machinery used to harvest and transport the stone, the less human labor will be needed. However, paying operators for the machinery can still result in fairly high labor costs.

Health Warning

Dust from stone and mortar mixes is high in silica. Wear adequate breathing protection.

Skill level required for homeowners: Moderate to high

Stonemasonry is a well-established trade with a long history. A good mason can create stone foundation walls that are beautiful, strong and durable in an efficient manner. However, with some training and practice it is possible for an amateur to create a dry-stacked or mortared foundation that is completely serviceable, if not as aesthetically pleasing as one built by a professional. It is definitely not advisable to attempt a stone foundation without any training at all, and if the finished look of the foundation is of primary importance, hiring a mason is a good idea. Owner-builders can offer to provide labor for the mason; having a helper who moves the stone and mixes mortar will minimize the mason’s time on-site and keep costs lower.

Sourcing & availability: Easy to moderate

Viable stone for foundations is widely available but not necessarily easy to source. Site stone must have the right properties and exist in enough quantity to do the job. Local quarries and masonry supply outlets may have locally harvested options.

Durability: High to Very High

Well-built stone foundations are among the most durable options available. They have a long history of performance in a wide variety of climates and building types. While older stone basement walls tended to be leaky, such moisture issues can be addressed by not having a basement and using the wall as a frost wall or perimeter beam only, or by using modern drainage and waterproofing techniques for basements.

Code compliance

Despite their historical precedents, most codes do not recognize mortared or dry stone as an accepted solution. Mortared stone has sufficient supporting data and history for a successful alternative compliance application. Dry-stacked walls will be more difficult to justify due to the reliance on workmanship to achieve a high-quality wall.

A structural engineer should be able to provide the calculations and support required to get either type of foundation wall accepted.

Indoor air quality: n/a

Stone foundation walls will have little direct impact on indoor air quality. By keeping the floors and walls of the building dry they can help to prevent other IAQ issues.

Resources for further research

Gallagher, A. Robert., Joe Piazza, and Sean Malone. Building Dry-Stack Stone Walls. Atglen, PA: Schiffer, 2008. Print.

McRaven, Charles. Building with Stone. Pownal, VT: Storey Communications, 1989. Print.

Long, Charles K. The Stonebuilder’s Primer: A Step-by-Step Guide for Owner-Builders. Willowdale, Ont.: Firefly, 1998. Print.

Cramb, Ian. The Art of the Stonemason. White Hall, VA: Betterway Publications, 1992. Print.

McRaven, Charles. Stonework: Techniques and Projects. Pownal, VT: Storey, 1997. Print.

McRaven, Charles. Building Stone Walls. Pownal, VT: Storey, 1999. Print.

Flynn, Brenda. The Complete Guide to Building with Rocks and Stone: Stonework Projects and Techniques Explained Simply. Ocala, FL: Atlantic Group, 2011. Print.

Future development

Stone foundations (and mortars) have a long history and it is unlikely that the state of the art will experience dramatic advances or changes. As you inquire about stone for foundations, be aware that many people will discourage you from this option. Stone foundations have associations with older homes in which the foundations experience issues (after a hundred years or so). A well-built, properly drained stone foundation should be able to avoid these issues, but convincing others of this may be difficult.

Tips for a successful stone foundation

1. Ensure you have an adequate supply of stone. Mixing different types/sources of stone is not usually recommended, and importing stone can be expensive, so don’t start unless you know you have enough to finish the job.

2. Have your stone assessed by somebody knowledgeable, especially if you are site harvesting. There are some kinds of stone that look suitable for building but have properties that are not well suited for foundations.

3. Learn proper stone-laying technique before starting the foundation. There are many tricks to making a structurally sound stone wall, whether dry-stacked or mortared.

4. Ensure you have adequate time to build the foundation. Stone foundations are labor intensive and are not built quickly.

5. Properly separate the walls above from the foundation below. Moisture can “wick” through certain kinds of stone and most kinds of mortar joints, and must be prevented from entering the bottom of the wall. A slate cap was a traditional way of preventing rising moisture issues, or there are modern sealants/barriers that can be used.

6. Provide excellent drainage around the stone foundation. Excessive wetting, especially in freeze/thaw conditions, are hard on mortared stone foundations. And because dry-stack foundations don’t keep moisture out, proper precautions must be taken to keep water out from under the building.