gypsum Board & Drywall

cladding: MATERIALS ENCYcLOPEDIA

Applications for this system

Interior wall and ceiling sheathing

Exterior wall sheathing (if specified for exterior purposes)

Basic materials

Gypsum

Paper coating (interior uses)

Fiberglass coating (exterior uses)

Chemical additives (dependent on type of panel)

Joint tape or mesh

Joint compound

Fasteners

Corner beads and other trim accessories

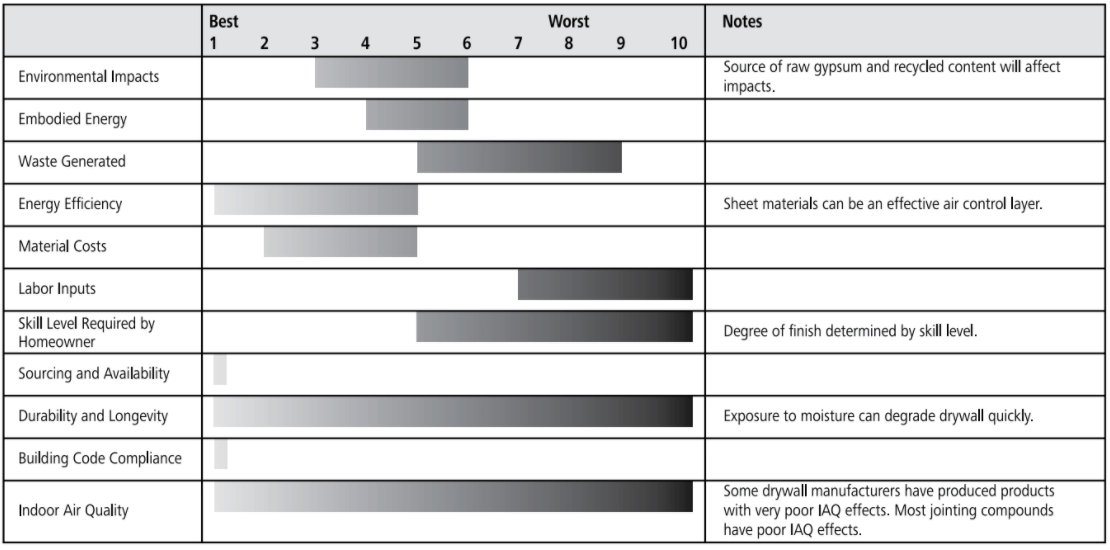

Ratings Chart for Drywall sheathing

The ratings chart shows comparative performance in each criteria category. Click on the tabs below for detailed analysis of each criteria.

- HOW THE SYSTEM WORKS

- ENVIRONMENTAL IMPACTS

- WASTE

- EMBODIED CARBON

- ENERGY EFFICIENCY

- MATERIAL COSTS

- LABOUR INPUT

- SKILL LEVEL REQUIRED

- SOURCING & AVAILABILITY

- DURABILITY

- CODE COMPLIANCE

- INDOOR AIR QUALITY

- RESOURCES

- FUTURE DEVELOPMENT

Drywall System

Gypsum is obtained from quarries or from recycled flue gasses at coal-burning plants. It is dried, ground and heated to alter its chemistry. It is then mixed with water and chemical additives and set between paper or fiberglass sheets. The sheets are oven-cured in a multi-stage process of descending temperatures.

The sheets are made in a variety of thicknesses (1/4, 3/8, 1/2 and 5/8 inch are common) and standard dimensions of 48 and 54 inches by 96, 120 or 144 inches to suit common wall-framing dimensions. Each sheet has two tapered edges that allow for jointing compound to be applied while achieving a smooth finished surface.

The sheets are fastened to wall and ceiling framing with specialty screws, and the screw heads are covered with joint compound.

Joints are bridged with a paper or mesh tape and a gypsum-based jointing compound that is applied in several coats, with sanding to smooth between coats.

Interior gypsum board is commonly painted, but can also be a substrate for finish plasters.

Exterior gypsum products are for sheathing only, and the joints are not covered. These materials are used in conjunction with a variety of cladding options.

Environmental Impact Rating

Harvesting — Moderate

The bulk of the material in the panels is gypsum, a soft rock quarried from surface-based pits, most of which have been long established. Impacts can include habitat destruction and surface and ground water contamination. Some drywall manufacturers use gypsum obtained from industrial chimney flues, reducing the need for virgin gypsum.

Manufacturing — Moderate

Heat is applied twice in the manufacturing process, when the raw gypsum is initially calcined and again to dry the panels once they have been formed. The temperatures for these processes are lower than other manufactured mineral and/or sheet products, but still require substantial energy input.

Manufacturing gypsum board requires a lot of water, but effluent levels are not high as the water is dried out of the panels in kilns.

A wide number of additives are mixed with the gypsum in relatively small quantities. These include paper and/or fiberglass fiber, soap-based foaming agents, plasticizers, gypsum crystal, EDTA, starch, mildew resistant agent and wax emulsion for water-resistant drywall. All the additives in drywall will have a range of impacts during their manufacturing processes.

Transportation — Low to High

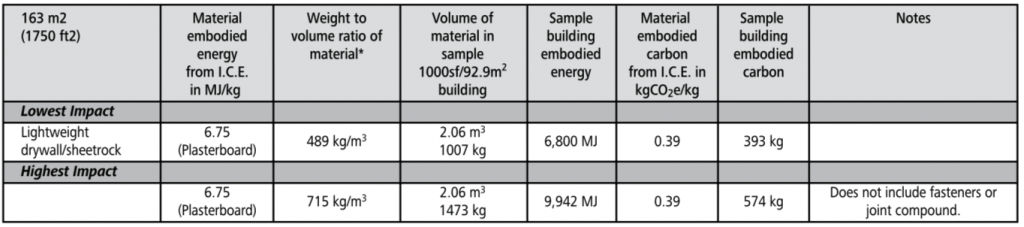

Sample building uses 1,007 – 1,473 kg of drywall for interior wall sheathing:

1.5 – 2.2 MJ per km by 15 ton truck

0.95 – 1.4 MJ per km by 35 ton truck

0.25 – 0.37 MJ per km by rail

0.16 – 0.24 MJ per km by ocean freight

Gypsum board production is centralized and manufacturing plants exist close to most population centers in North America. However, complexities in the supply chain does not guarantee that drywall purchased in a region was produced in that region.

Installation — Moderate to High

The installation of gypsum board creates a high amount of dust on the building site, especially during the sanding of joints. The dust is extremely fine and can become dispersed throughout the home (including heating and ventilation ductwork) and in the environment around the home. Many joint compounds contain anti-fungal agents and other toxic chemicals that installers will not be able to contain fully.

Waste: moderate to high

Compostable — None.

Recyclable — Drywall offcuts. Drywall recycling programs are starting to become more common. If such programs exist, all scrap will be able to be diverted. Quantities tend to be high.

Landfill — Drywall offcuts. If no recycling program is available, offcuts will go to landfill.

Chart of Embodied energy & carbon

Energy Efficiency

Gypsum board products may be used as the primary air control layer on the interior and/or exterior if all seams, penetrations and intersections are properly gasketed and/or caulked. Gypsum board does not contribute to thermal control.

Material costs: Low to moderate

Scale of production and price competition for this widely-used material have led to economies of scale that result in pricing that is lower than embodied energy inputs would typically require.

Labour Input: High

Interior gypsum board is a multiple-stage material to install. Sheets must be cut to size and mounted, joints taped/meshed, and joint compound applied in two or three coats with drying time and sanding required between each. Professional tools can greatly reduce labor input.

Health Warnings

Dust from drywall and in particular joint compounds is toxic and proper breathing protection must be worn.

Skill level required for homeowners

Preparation of substrate — Easy

Basic framing and carpentry skills.

Installation of sheathing — Easy to Difficult

Large sheets are easy to install, level of difficulty increases with quantity and complexity of cuts, penetrations and intersections.

Finishing of sheathing — Difficult

Mudding and sanding joints, corner beads and intersections to a good degree of finish requires experience.

Exterior gypsum sheathing does not require jointing.

Sourcing & availability: Easy

Gypsum products are widely available through building supply outlets and masonry supply stores.

Durability: low to High

Gypsum board is susceptible to moisture damage, and will deteriorate quickly when wet repeatedly or continuously. Kept dry, the material is soft and dents and chips relatively easily, but will last a long time.

Code compliance

Acceptable solution in all codes. Particular types of drywall may be required for specific purposes (fire code, moisture resistance).

Indoor air quality: low to high

There can be minor to serious issues with gypsum board and IAQ. Synthetic gypsum (which represents a growing percentage of all available gypsum products) is reclaimed from the chimneys of coal-burning installations and may contain contaminants, including sulfur and heavy metals. There are lawsuits currently pending in the United States regarding sulfur gas contamination of homes from drywall sourced from Chinese and American synthetic gypsum. While the number of claims is small in comparison to the amount of drywall installed, the precautionary principle suggests avoiding synthetic gypsum products.

Non-synthetic gypsum board for interior use is typically faced with paper that is adhered using starch-based glues. This combination is an excellent food source for mold, and drywall in humid or moist conditions can easily become moldy, with dramatic impacts on IAQ.

Pre-mixed joint compound will contain fungicides/biocides that are persistent in the environment. Most wet and dry joint compounds will contain formaldehyde, ethylene vinyl acetate latex and other additives. These will be listed on the product’s MSDS sheet.

Complicating the issue is the level of dust created when sanding joint compound. The resulting dust is very fine and pervasive, carrying traces of all the chemical additives as well as silica throughout the home. Heating and ventilation ducts are particularly vulnerable to being coated in this dust.

There are a few brands of joint compound that do not contain any chemical additives and are considered hypoallergenic. Note that the dust from these compounds is still high in silica and should not be inhaled.

Resources for further research

Ferguson, Myron R. Drywall: Professional Techniques for Great Results. Newtown, CT: Taunton, 2002. Print.

Spence, William Perkins. Installing and Finishing Drywall. New York: Sterling, 1998. Print.

Future development

The amount of potentially dangerous synthetic gypsum being used in the industry is an issue that is currently controversial, and the next decade will see developments that either lead to safer synthetic gypsum or proof that the material is not as dangerous as some currently claim.

Less toxic joint compound will likely make inroads into the industry, with R&D directed toward eliminating toxic chemicals from the material.

Drywall is likely to remain the dominant type of interior wall sheathing as its market acceptance, convenience and aesthetic are key to the majority of construction in North America.

Tips for successful drywall sheathing

1. There are many good resources for homeowners wishing to install drywall. However, there will be a learning curve to achieving good jointing skills. It is good to practice drywall jointing in less obvious areas until results meet expectations.

2. Interior drywall is available in many varieties, including fire code-approved, lightweight and moist-area versions. Be sure you are using the correct product for your specific requirements.

3. The drywall industry is so well established that professional drywall installers have tools, equipment and techniques that allow them to do a job much faster and with much better results than most homeowners. Competition is ubiquitous enough that prices are surprising low, and even a committed DIYer may find it worthwhile to hire out the job.