cotton Batt

Insulation: MATERIALS ENCYcLOPEDIA

Applications for this system

Wall insulation

Ceiling insulation

Raised floor insulation

Basic materials

Post-industrial recycled cotton

Boron-based fire-retardant

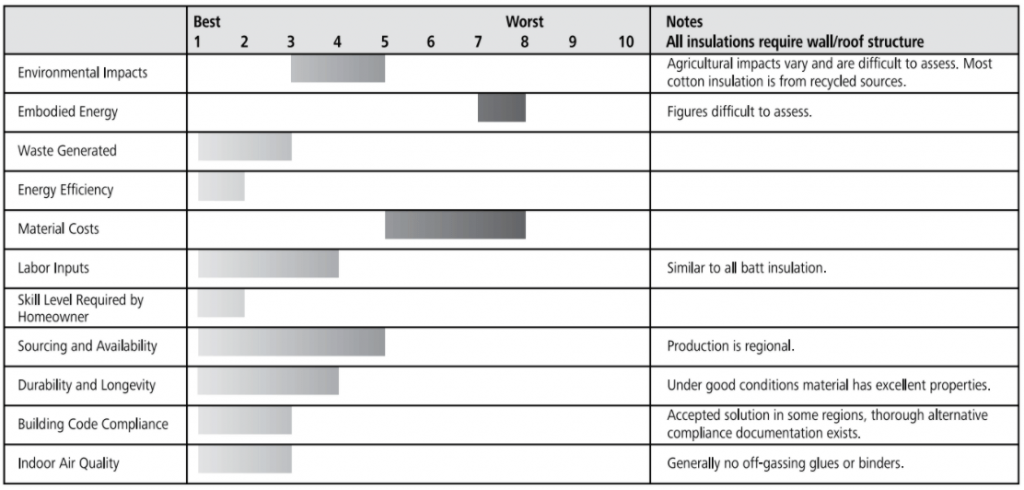

Ratings Chart for Cotton Batt Insulation

The ratings chart shows comparative performance in each criteria category. Click on the tabs below for detailed analysis of each criteria.

- HOW THE SYSTEM WORKS

- ENVIRONMENTAL IMPACTS

- WASTE

- EMBODIED CARBON

- ENERGY EFFICIENCY

- MATERIAL COSTS

- LABOUR INPUT

- SKILL LEVEL REQUIRED

- SOURCING & AVAILABILITY

- DURABILITY

- CODE COMPLIANCE

- INDOOR AIR QUALITY

- RESOURCES

- FUTURE DEVELOPMENT

Cotton Batt System

Denim off-cuts, sometimes combined with polyester fiber, are spun into insulation batts in a range of sizes to fit common stud cavity dimensions.

Environmental Impact Rating

Harvesting — Low

Cotton batt insulation is made from offcuts produced by the clothing industry, in particular from denim jean manufacturing.

Manufacturing — Moderate

The shredding and binding of the cotton requires numerous mechanical processes that have low or moderate impacts related to the energy use of the machinery.

Transportation — Low to High

Sample building uses 1,023 kg of cotton insulation:

1.5 MJ per km by 15 ton truck

0.96 MJ per km by 35 ton truck

There are currently few production facilities in North America. Insulation batts are a high-volume material and accrue impacts proportional to distance traveled.

Installation — Negligible

The insulation batts are formed without the use of glues and carry no health warnings on their labels

Waste: moderate

Recyclable — Plastic packaging.

Landfill — Insulation offcuts.

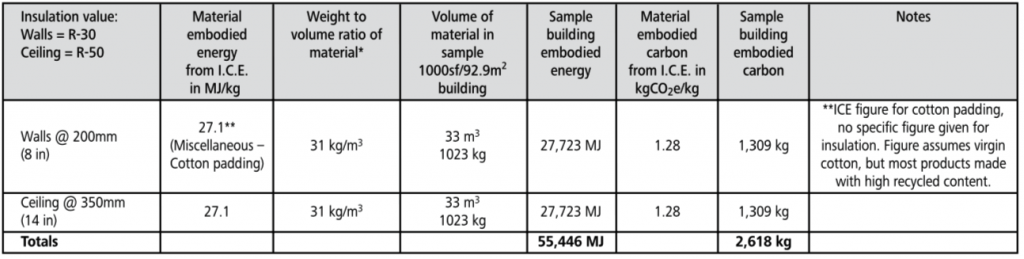

Chart of Embodied energy & carbon

Energy Efficiency: high

R-value: ~3.7 (RSI-0.65) per inch

Cotton insulation has a fairly high R-value, but must be properly installed to avoid settling and voids around framing members and other obstacles in the wall. The material is vapor-permeable and has a high amount of moisture storage capacity, but requires a separate air control layer.

Material costs: moderate to high

Cotton batt insulation is not widely distributed, and costs are higher than other batt products with wider distribution.

Labour Input: low to moderate

Cotton batts have similar installation times as other batt insulations. Cutting of the cotton batts can be more difficult and time-consuming than comparable materials, but batts come with pre-cut lines that assist with resizing.

Skill level required for homeowners: Low

The installation of batt insulation is very straightforward, but care must be taken to ensure a tight fit in all cavities with no gaps or voids, to ensure full thermal value.

Sourcing & availability: low to moderate

Cotton batts are not commonly available at all building supply stores, but distribution has widened considerably in the past few years and will likely continue to expand to meet growing demand.

Durability: moderate to High

Kept reasonably dry, this insulation will have a long lifespan. Cotton could provide a food source for mold in overly moist conditions, but the boron added as a fire retardant also has anti-fungal properties.

Code compliance

All applicable code standards for batt insulation are met or exceeded.

Indoor air quality: High

Batt insulation is usually contained behind an air or vapor control barrier and a wall finish, and does not directly affect IAQ. Cotton insulation does release some dust during installation, but does not contain any known carcinogens or off-gassing binders and the fibers themselves are not considered dangerous.

Resources for further research

Bynum, Richard T. Insulation Handbook. New York: McGraw-Hill, 2001. Print.

Future development

Cotton insulation is likely to grow in popularity as it is compatible with conventional building methods but has lower embodied energy and minimal health risks compared to conventional batts. More manufacturing facilities and better distribution will accompany greater demand.

Tips for successful cotton batt insulation

Batt installations must be free of voids and gaps to achieve maximum thermal performance. Manufacturers will provide specifications for installation.