Tile

Flooring: MATERIALS ENCYcLOPEDIA

Applications for this system

Finished flooring. Can be applied on wooden sub-floors, but may require underlayment. Can be applied directly over slab floors.

Basic materials

Natural tiles are made from stone or slate

Manufactured clay tiles are made from earthenware, stoneware or porcelain

Manufactured terrazzo tiles are made from aggregate and concrete

Manufactured tiles are sometimes made from glass and binders

Adhesives for tiles include cement mortar, modified cement mortar and glue adhesives

Underlayment includes plywood, cement board and/or sheet barrier materials

Grout between tiles is made from cement or modified cement

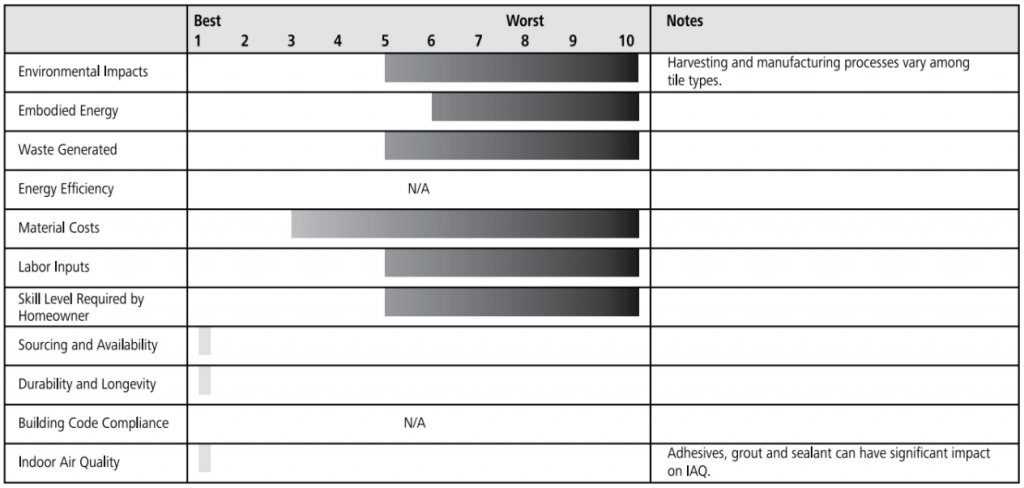

Ratings Chart for Tile flooring

The ratings chart shows comparative performance in each criteria category. Click on the tabs below for detailed analysis of each criteria.

- HOW THE SYSTEM WORKS

- ENVIRONMENTAL IMPACTS

- WASTE

- EMBODIED CARBON

- ENERGY EFFICIENCY

- MATERIAL COSTS

- LABOUR INPUT

- SKILL LEVEL REQUIRED

- SOURCING & AVAILABILITY

- DURABILITY

- CODE COMPLIANCE

- INDOOR AIR QUALITY

- RESOURCES

- FUTURE DEVELOPMENT

Tile System

Natural stone

Tiles are cut or quarried from deposits of a stone that is suitable for flooring. They may be left relatively rough and matte in finish, honed perfectly smooth or polished to a high gloss. They are cut into tiles of a desired size for a particular installation.

Clay tiles

Tiles are made from clay, aggregates, pigments or dyes and sometimes mineral fluxes. These are fired at a high temperature; the higher the temperature, the harder and less porous the finished tile. Many tiles are then glazed using mineral and/or petrochemical glazes, which are fired onto the surface of the tile during a second trip to the kiln.

Terrazzo tiles

Tiles are made by mixing a cement-based binder with aggregate and honing and polishing the resulting tile to expose a pattern of aggregate and binder in the finished surface.

Each type of tile is laid in a similar way. Individual tiles are set into a bed of adhesive on the sub-floor in a chosen pattern. Once set in the adhesive, the gaps between the tiles are filled with grout to the desired level.

Environmental Impact Rating

Harvesting — Moderate

Natural stone, clay and terrazzo ingredients are non-renewable but abundant resources that are widely available. They are quarried or dug from geological deposits. Most quarries and pits have been long established, so are not responsible for the disturbance of untouched ecosystems. Impact at the quarry tends to be low, and can include interference with and silting of ground and surface water and the creation of airborne dust. Little to no contaminated effluent is created and no chemicals are used in obtaining these materials.

The balance of materials required for tiling can have moderate to high impacts. Grout and mortar are often cement based, and require quarrying to harvest. Petrochemical additives to mortars and grouts, in particular chemical adhesives, often require intensive and polluting processes to harvest raw materials.

Manufacturing

Natural Stone — Low

Stone is mechanically cut and/or split into tiles in a process that uses relatively little energy and produces little to no effluent or pollution. Honing and polishing are mechanical procedures that are also low-intensity.

Clay Tiles — Moderate to Very High

The production and forming of raw clay into tiles uses relatively little energy and produces little to no effluent or pollution. The kilns used to fire tiles are very energy-intensive. Fuels used include natural gas, oil, coal and wood, in large quantities, with significant pollution and greenhouse gas emissions. The harder the tile, the higher the firing temperature and the longer the time spent in the kiln. Soft tiles, like “Mexican” clay tiles, are at the low end of the spectrum, with porcelain tiles at the high end. The addition of a second firing for glazing adds further to the energy input and the pollution output. The addition of glazes can introduce toxic chemicals into the process (depending on the type of glaze) and increase quantities of air pollution and effluent.

Terrazzo Tiles — High

Terrazzo is a type of concrete, using portland cement to bind a mixture of aggregates. The creation of portland cement is high intensity, with limestone being fired in kilns to very high sustained temperatures. Fuels used include natural gas, oil, coal, landfill waste and coal, in large quantities, with significant pollution and very significant greenhouse gas emissions. Once formed and cured, the polishing process is mechanical and of relatively low intensity, with airborne particulate as the main waste.

Balance of Materials — Moderate to Very High

Mortar and grout carry the same impacts as any cement-based material, though the quantities are relatively small. Chemical additives to mortar and grout, in particular tile adhesives, tend to be very intensive in their production and can produce high levels of toxic emissions and byproducts during production.

Transportation — Moderate to Very High

Sample building uses 1,406 – 2,035 kg of floor tile:

2.1 – 3.1 MJ per km by 15 ton truck

1.3 – 1.9 MJ per km by 35 ton truck

0.22 – 0.33 MJ per km by ocean freight

All tile products are very heavy, and incur significant transportation impacts based on distance traveled. If raw materials are shipped long distances to point of manufacture, this will add to the total impacts. The majority of clay tile sold in North America is manufactured in Europe or Asia, and has significant transportation impacts.

Installation — Low to Moderate

Tile is often cut with a grinder or saw, and if done while dry can create a significant amount of airborne dust that is high in silica content.

Waste: high

Compostable — Unglazed tile offcuts can be left in the environment as aggregate.

Landfill — Glazed tile offcuts, containers from adhesives and grout. Quantities low to high.

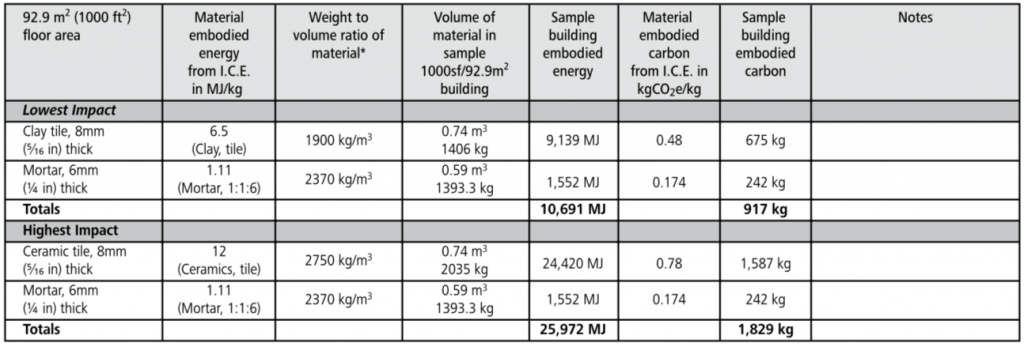

Chart of Embodied energy & carbon

Energy Efficiency: n/a

A tile floor will have no effect on energy efficiency.

Material costs: Low to high

Floor tiles include a wide range of products with highly variable price points.

Labour Input: High

Tiling is a multi-stage process involving a high amount of labor. In many cases, work must be done to prepare the substrate for tiling. Then comes layout, which must be performed carefully; tile cutting, a time–consuming task; and the actual laying of the tiles, which must also be done carefully. Complicated patterns are especially intensive. Grouting is a separate process and requires significant cleanup time, and a sealant is often applied to the grout or the whole floor, adding another step.

A number of specific tools will need to be purchased for a tile job, including a mechanical or manual tile cutter, nibblers, mortar trowel and sponge float.

Skill level required for homeowners

Preparation of sub-floor — Easy to Difficult

Tile adhesive/mortar can be applied directly to some slab floors. Wooden sub-floors may be able to accept tile directly, or may require one or more layers of underlayment to ensure a crack-free installation. The more complex the underlayment, the more difficult the preparation for tiling. Preparation for waterproof tile installations in showers and baths adds a degree of difficulty.

Installation of floor — Easy to Difficult

The size, shape and layout of the tiles will determine the ease of the installation. Complex layouts and the need for lots of cutting and fitting will raise the level of difficulty, as will the need to make a waterproof installation.

Finishing of floor — Easy to Moderate

Grouting is fairly simple, but may need to be done in a few stages and must be done carefully to get even results. Understanding the timing for grouting can take some practice, as sponging too soon can remove too much grout from the cracks but waiting too long can result in grout that is too high or uneven.

Sourcing & availability: Easy

Tile and all that is required to install it is available widely, through building supply outlets and specialty tile shops.

Durability: Very High

Well-installed tile has a very long lifespan. The tile itself will last for hundreds of years, with the lifespan of the mortar or adhesive determining the serviceable life of the floor. Modern mortars and adhesives can typically be relied upon for thirty to sixty years or more. Uncracked tile can be relaid with new mortar or adhesive to continue the life of the floor.

Code compliance

Most codes are not prescriptive when it comes to finished flooring materials, as long as the sub-floor has been constructed to code and in a manner intended to support the dead load imposed by the flooring.

Indoor air quality: high

Tile is unlikely to have a negative impact on IAQ, but the mortars and/or adhesives can be mildly to extremely toxic. In particular, chemical adhesives often carry serious warnings about the inhalation of vapors, with potential cancer-causing and birth defect-causing effects. Be sure to select mortars or adhesives that have been formulated to have the least possible impact on IAQ.

Resources for further research

The Complete Guide to Ceramic Tile. Minneapolis, MN: Creative Publishing International, 2010. Print.

The Complete Guide to Flooring. Minneapolis, MN: Creative Publishing International, 2010. Print.

Future development

Tiling has been around for thousands of years, and some installations are still intact. Recent changes in tiling have come in the form of new ways to color tile (including inexpensive screen printing) and chemical additives for grout, mortar and adhesives. These modern additions to tiling are also the more high-impact elements, and a homeowner looking to minimize environmental impacts will choose to tile the old-fashioned way, with a lime-based mortar and grout that is chemical free. It takes longer for this mortar to set, but it’s an excellent example of a return to past methods being the best direction for the future.

There is work being done on making less-toxic adhesives. If using chemical adhesives, look for those that have third-party certification for air quality and off-gassing.

Tips for a successful tile floor

1. Tile flooring must be placed on a very stable sub-floor, as deflection in the floor can cause cracking of the grout or the tile.

2. Each type of tile may require a particular type of underlayment and adhesive. Follow manufacturer’s instructions or the advice of an experienced tile installer.

3. Be aware of the different surfaces on tiles. Some will become very slippery when wet, and shouldn’t be used in areas where water can be expected to accumulate.

4. It is possible to be very creative with tile installation. A variety of patterns will be possible using the same size tiles, and tiles can be ordered in different sizes or cut on-site to further increase the possibilities. Whenever a creative tile pattern is being used, carefully lay out the pattern before beginning the installation.

5. The gaps between tiles can be set with spacers (or chalk lines) to a variety of widths. Be sure to consider the aesthetics of the gaps when creating a tile surface. Choose grout material and color to suit the width of the gaps.