Limewash & Lime Paint

Finishes: MATERIALS ENCYcLOPEDIA

Applications for this system

Interior walls and ceilings

Exterior walls

Porous surfaces

Not suitable for use on:

– Floors

– Non-porous surfaces

Basic materials

Hydrated or hydraulic lime

Aggregate

Binder (usually casein)

Fibre (if required)

Pigment

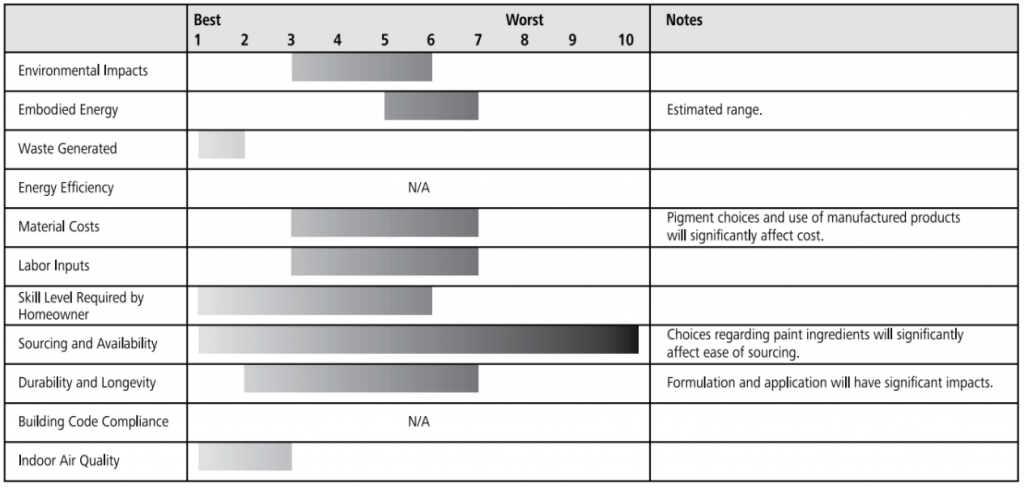

Ratings Chart for Limewash and lime paint

The ratings chart shows comparative performance in each criteria category. Click on the tabs below for detailed analysis of each criteria.

- HOW THE SYSTEM WORKS

- ENVIRONMENTAL IMPACTS

- WASTE

- MATERIAL COSTS

- LABOUR INPUT

- SKILL LEVEL REQUIRED

- SOURCING & AVAILABILITY

- DURABILITY

- INDOOR AIR QUALITY

- RESOURCES

- FUTURE DEVELOPMENT

Limewash and lime paint system

Lime wash and paint are based on the ability of powdered, fired limestone to be mixed with water, applied to a surface and then chemically re-carbonize into a durable material that resembles the original stone. Both are vapor permeable and highly UV resistant, and will not soften or erode when exposed to water. The lime will reach its working strength in thirty days, and continue to strengthen over time. Multiple coats require curing time between applications of at least 24 hours, to allow time for carbonization to begin. For thicker coats, longer curing time between coats is recommended.

Lime Wash

In a lime wash, the only materials are lime and water (and pigment, if desired). The materials are mixed to a paint-like consistency and applied to the porous substrate, usually with a special heavy-bristle whitewash brush. Anything from one thin coat to multiple heavy coats may be applied, depending on the desired opacity of the finish and the degree of protection desired for the substrate. A lime wash gives a bright white finish unless pigmented.

Lime Paint

Lime paint can include a wide variety of combinations of aggregate, binder and fiber along with the lime, water and pigment. Some binders work chemically to bring desired properties to the paint (pozzolanic reactions, chemical binding), others help give the paint a desired consistency and body. Binders can add a degree of water repellency not found in a straight whitewash, and may add a reasonable amount of protection for the substrate material. The addition of casein to lime paint creates the calcium caseinate found in milk paint. There is a blurry line where casein-lime paint stops and milk paint starts.

The addition of aggregate and/or fiber in the mix gives lime paint enough body to create thicker coats than is possible with lime wash. Lime paint can fully cover a substrate, filling small cracks and pores and surface irregularities that would show through lime wash.

Untinted lime paint will be white, but the brightness will be affected by the type and quantity of aggregate.

Environmental Impact Rating

Harvesting — Moderate to High

Limestone is a non-renewable but abundantly available material. It is mechanically extracted from quarries. Impacts can include habitat destruction, surface and ground water interference and contamination.

Manufacturing — High

Limestone is mechanically crushed and heated (900–1100 ∞C / 1650–2000 ∞F). This is an energy-intensive process during which large amounts of fossil fuels are burned, contributing to habitat destruction and air and water pollution and carbon emissions.

Transportation — Moderate to High

Limestone is available in many regions, but is not necessarily harvested and processed in all regions. Impacts for this heavy material will vary depending on distance from the site. Natural hydraulic lime (NHL) most commonly comes from France or Portugal, carrying high transportation impacts for use in North America.

Installation — Negligible

Waste: Negligible

Compostable — Lime wash and paint can be placed in compost. Straight lime mixes are very basic, and may change the pH of compost or soil.

Recyclable — Bags for lime.

Material costs: Low

Labour Input: moderate

The mixing process may be very straightforward or require multiple steps. Application time will be similar to conventional paint.

Health Warnings

Lime and aggregate have high silica content. Breathing protection should be worn when working with powdered materials. Wet lime is caustic to skin, and gloves and eye protection should be worn.

Skill level required for homeowners

Preparation of substrate — Easy

No preparation is required for suitable substrates.

Application of finish — Easy to Moderate

Brush or roller application.

Sourcing & availability: Easy to Difficult

Ingredients are widely available from masonry supply stores. Pigment may be found at artist supply outlets. Casein, if used, must be sought from industrial suppliers or skim milk powder may be used.

Commercial lime paint mixes are available from sustainable building supply stores or directly from manufacturers.

Durability: moderate

Lime paints are very durable, as they form a mineral coating that is not prone to deterioration from moisture or sunlight. However, as lime coatings don’t typically provide much protection from water penetration, the main cause of deterioration is from water damage to the substrate behind the lime finish. Expansion, contraction and freeze/thaw issues can cause the lime finish to spall and flake in very wet locations, depending on the vulnerability of the substrate to water.

Lime coatings can be reapplied indefinitely. If recoating a flaking lime coating, sand or brush away any loose lime before reapplying.

Indoor air quality: high

Lime paints will have no negative impact on IAQ. However, if the finish is very dusty on the surface it will be a source of fine silica dust in the home. If an interior lime finish is dusting, recoat or apply a sealant.

The basic nature of lime makes it antiseptic and unlikely to support mold or mildew growth.

Resources for further research

Weismann, Adam, and Katy Bryce. Using Natural Finishes: Lime- and Earth-Based Plasters, Renders and Paints: A Step-by-Step Guide. Totnes, UK: Green, 2008. Print.

Edwards, Lynn, and Julia Lawless. The Natural Paint Book: A Complete Guide to Natural Paints, Recipes, and Finishes. Emmaus, PA: Rodale, 2002. Print.

Future development

Lime finishes have been used for thousands of years, and the basic recipes have not changed much over time. Modern manufacturing processes have made lime more consistent in quality and properties.

Natural chemistry may provide new formulations of lime-based paints that will retain the positive qualities and increase adhesion and water repellency.

The desire for nontoxic finishes may result in a wider demand for lime-based paints.

Tips for a successful limewash/lime paint finish

1. The high pH of lime will affect the coloration of most pigments, tending to make them lighter in tone. Be sure to experiment with pigments and allow the wash or paint to cure for at least 24 hours to see what the finished color will look like.

2. While highly resistant to degradation from wetting, lime wash offers little resistance to water penetration, while some lime paint formulations can be very water repellent. Be sure to match the desired level of water protection with the appropriate mixture.

3. Lime wash and paint will tend to have a matte finish and slightly rough texture, unless admixtures are used to give a smoother, shinier surface.

4. Lime finishes will often be different in appearance on wood surfaces than on plaster or other masonry.