clay tile

Roofing: MATERIALS ENCYCLOPEDIA

Applications for this system

Roof sheathing

Basic materials

Fired clay tiles

Solid roof decking or strapping

Fasteners

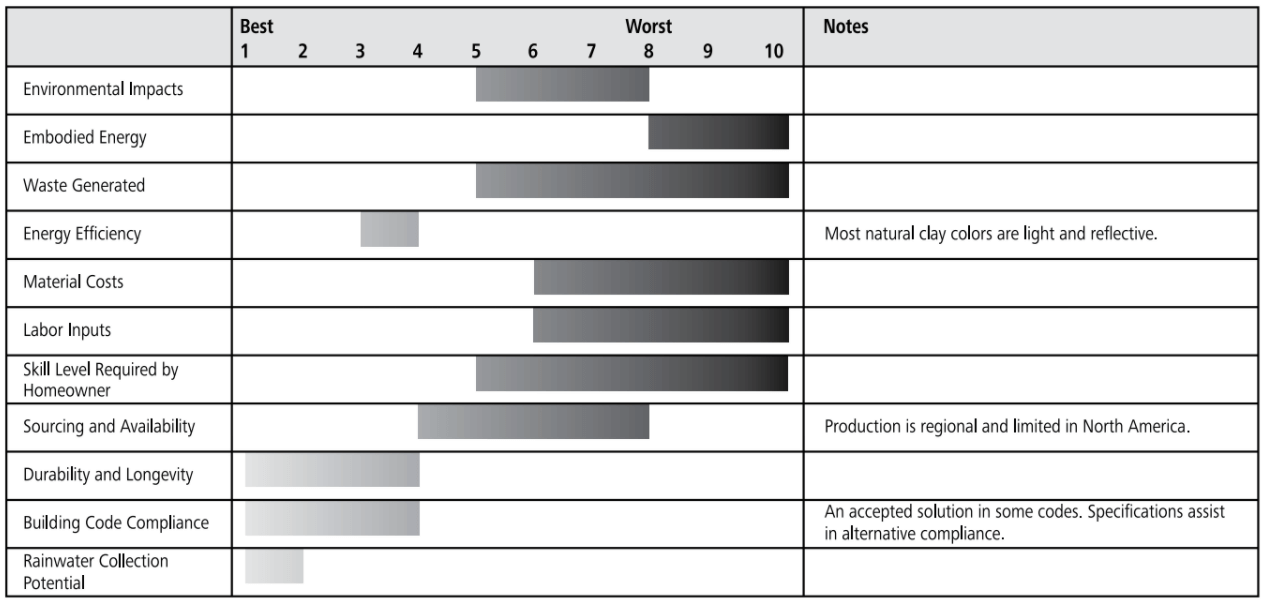

Ratings Chart for Clay tile roofs

The ratings chart shows comparative performance in each criteria category. Click on the tabs below for detailed analysis of each criteria.

- HOW THE SYSTEM WORKS

- ENVIRONMENTAL IMPACTS

- WASTE

- EMBODIED CARBON

- ENERGY EFFICIENCY

- MATERIAL COSTS

- LABOUR INPUT

- SKILL LEVEL REQUIRED

- SOURCING & AVAILABILITY

- DURABILITY

- CODE COMPLIANCE

- RAINWATER COLLECTION CAPABILITY

- RESOURCES

- FUTURE DEVELOPMENT

Clay tile roof System

Clay roofing tiles are made from naturally occurring clay and sand, fired in a kiln at high temperature. Some tile manufacturers will add fluorite, quartz, feldspar or other fluxes to reduce porosity. The tiles are formed when the clay mixture is wet, using a variety of form shapes to meet a desired appearance. The color of the tile depends on the color of the clay, with shades of red being the most common. Tints can be added to provide a range of color options.

While there are a multitude of different clay tile profiles available, the system is essentially like all other shingle-style roofing materials. A solid roof deck or appropriate strapping is placed over the framing, along with any required membrane or underlayment. Overlapping courses are fastened to the roof such that there are no exposed seams or joints. The type of overlap and/or interlock on clay tiles will vary depending on the profile of the tile. The tile will have one or more holes cast into the top edge for nailing (using galvanized or copper nails) and some form of interlocking between neighbouring tiles. Some systems use metal clips that slip into the tile and are tacked to the roof deck.

At hips and ridges, tiles cast with an appropriate profile are mortared in place, typically with a cement-based mortar. Penetrations through the roof like vents or chimneys are handled with cast tile pieces and/or metal flashing. Cuts are made in tiles at hip and valley with a tile cropper or a wet saw.

In northern climates, clay roof tiles gained a poor reputation when European-style tiles were prone to cracking due to water absorption and freeze/thaw cycles. Higher firing temperatures and the addition of mineral-based fluxes have reduced porosity to the point where clay tiles are suitable for harsher climates, but the poor reputation lingers.

Environmental Impact Rating

Harvesting — Low to moderate

The clay that forms the bulk of the material in a roof tile is an abundant resource, with useful deposits in many regions of North America. Clay pits are usually shallow, surface-based harvesting operations that do not use any chemical processes on-site. Many clay pits are in or beside waterways, and pit operations can silt the water and disrupt flow patterns. In general, clay pits are not considered high-impact mining operations, and are excellent candidates for rehabilitation at the end of the pit’s lifespan.

Manufacturing — Moderate to high

Clay for tiles requires very little mechanical processing. It is ground up and squeezed into a homogeneous mix before being formed. This work is typically all completed by machine in factories, though traditionally it would have been done by hand on or near the building site. The largest impact from clay tiles comes from the firing process, during which the tiles are heated to temperatures of 900 to 1300 °C (1650 to 2350 °F) for several hours. No toxins are released from the clay during this process, but a lot of fossil fuels are consumed and emissions released into the atmosphere.

Tiles that are glazed or painted will require additional processes, and these can be more toxic. Paint coatings, in particular, can contain chemicals that are emitted into the atmosphere and/or mixed into water at the factory.

The mortar used at ridges and hips is a very small amount of material, but as it is cement based, it carries a high carbon footprint.

Transportation — Moderate to High

Sample building uses 5,125 kg of clay tiles:

7.7 MJ per km by 15 ton truck

4.8 MJ per km by 35 ton truck

1.3 MJ per km by rail

0.82 MJ per km by ocean freight

Production facilities are typically located very close to clay pits, minimizing the transportation of raw materials. With only a few manufacturers supplying the entire continent, this heavy material may have to travel long distances to reach some regions, accumulating high transportation impacts.

Installation

Clay tiles require the use of power tools for cutting. Chemical products used in mortar, caulking and flashing will be the items with the highest impact, as the tiles themselves are inert.

Waste: moderate to high

Compostable — Clay tile offcuts can be left in the environment or crushed to make aggregate or growing medium. Quantities will be negligible for simple roofs, but can be quite high if there are numerous hips and valleys.

Recyclable — Metal flashing offcuts and fasteners, wood strapping scrap. Quantities will be negligible for simple roofs, but can be moderate if there are numerous hips and valleys.

Landfill — Mortar bags, plywood decking. Quantities will be negligible for simple roofs, but can be moderate if there are numerous hips and valleys.

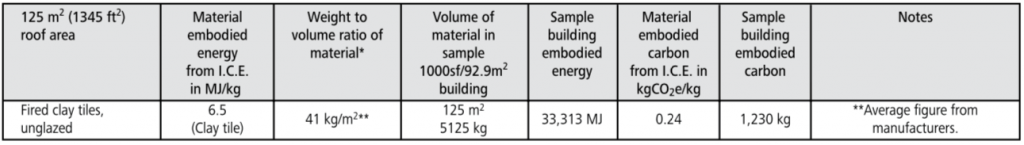

Chart of Embodied energy & carbon

Energy Efficiency: n/a

A tile roof has a moderate effect on cooling loads in hot weather, with most common tile colors certified as Cool Roof by the Cool Roof Rating Council, with a SRI value greater than 29.

Material costs: high

While clay tile roofing is quite cost competitive in other parts of the world, in North America it is much less common and therefore prices are comparatively high.

Labour Input: High to Very High

A clay tile roof is quite labor intensive. The labor input will depend on the size of tile, with larger tiles requiring less time to be laid. Clay tiles are heavy and fragile, so they take longer to move on-site than more flexible and lighter materials. Cutting custom tiles is slower than with most other shingles, and the mortaring of ridge and hip caps also takes additional time. The requirement to do the roofing without standing on the finished tiles will be an additional labor factor.

health warning

Working at heights to install roofing has inherent dangers. Proper setup and safety precautions should always be taken when working on a roof.

Skill level required for homeowners

Decking — Easy

Homeowners able to perform the general carpentry required to frame a roof would be able to deck the roof with strapping and/or sheet materials as required.

Membrane (if required) — Easy

If membranes must be used, they will typically be roll-type products that are straightforward to install.

Tiling — Moderate

A homeowner with some training, workshop experience or good written instruction can place the tiles on a simple roof. Practice is required for the cutting of tiles and to be able to nail quickly and accurately without damaging tiles.

Capping and Flashing — Difficult

Mortaring ceramic caps and creating flashing for valleys and roof penetrations requires experience or training from a professional. A workshop or practice on a small structure is recommended.

Sourcing & availability: moderate to Difficult

Clay tiles are not widely manufactured and distributed in North America, with only a handful of plants responsible for the production of the vast majority of tiles on the market. In regions where clay tiles are a common option, sources and competitive quotes for installation will be readily available. In many regions, clay tiles will be difficult to come by, and experienced installers rare.

Durability: moderate to High

Clay tile roofs can last from seventy-five to a hundred and fifty years. Cracked or broken tiles will need to be replaced as part of a regular maintenance schedule to keep the entire roof healthy. Annual checks of the roof and immediate replacement of damaged tiles is important.

Code compliance

Many building codes will recognize clay tiles as an accepted solution. Code officials will want to ensure that the roof structure has been designed to accept the weight of the tiles, and may insist on the need for an experienced installer. In jurisdictions where clay tiles are not part of the accepted solutions, adequate standards, documentation and historical precedent exist to make a reasonable case for their acceptance.

RAINWATER COLLECTION CAPABILITY: high

Earthbag foundations will have no direct impact on indoor air quality. A well-built foundation can help keep the floors and walls of the building dry and prevent other IAQ issues.

Resources for further research

ASTM C1167 astm.org/Standards/C1167.htm

Scharff, Robert, and Terry Kennedy. Roofing Handbook. New York: McGraw-Hill, 2001. Print.

Future development

Clay tiles are a dominant roofing choice in much of the world, but much less so in North America. Aesthetics and a reputation for being unreliable in cold climates are two factors that have limited their acceptance. As a very small part of the market in most regions, the cost of clay tiles and installation has also kept the system from becoming more widely accepted. With the development of tiles that meet cold-climate standards, there is no practical reason to avoid clay tile roofing. As a roofing product made from natural materials with a long lifespan and the ability to be recycled into useful growing medium at the end of its life, there is much to recommend clay tiles for sustainable buildings. It remains to be seen if these benefits will move the system into more widespread acceptance.

Tips for a successful clay tile roof

1. Include the significant dead weight of clay roofing tiles in calculations for the roof structure beneath.

2. At the design stage, be certain that details for the chosen profile of clay tile are incorporated. Some clay tiles are thicker than other roofing choices, so intersections with other building elements need to account for this depth. Chimneys and vent pipes should also be appropriately detailed.

3. In northern climates, select roof tiles that are made to ASTM Grade 1 standards (or equivalent). These tiles are made to have low porosity and to be able to handle repeated freeze/thaw cycles.

4. Installation must be done such that workers do not stand on finished sections of roofing, as this is the primary cause of failure of clay tiles. Roofing ladders, scaffolding or other work platforms must be used.

5. Care must be taken when nailing clay tiles. If the nail is left proud of the top of the tile, it could prevent the next tile from interlocking properly and can create a pressure point where a crack could occur. However, if the nail is driven too deeply (or the hammer misses it), the tile can crack.

6. Cutting clay roof tiles takes practice and appropriate tools. A tile cropper or a wet saw can be used to shape tile at hips and valleys, but first-timers are likely to break a few tiles while getting the hang of the process.

7. The mortaring of ridge and hip caps is done with a cement-based mortar formulated specifically for clay roof tiles. There will be mortaring procedures particular to each manufacturer’s tiles.