Perlite Loose-fill

Insulation: MATERIALS ENCYcLOPEDIA

Applications for this system

Loose-fill insulation for wall cavities

Loose-fill insulation under slab floors

Loose-fill attic insulation

Basic materials

Expanded, siliceous rock

Silicon treatment for water resistance

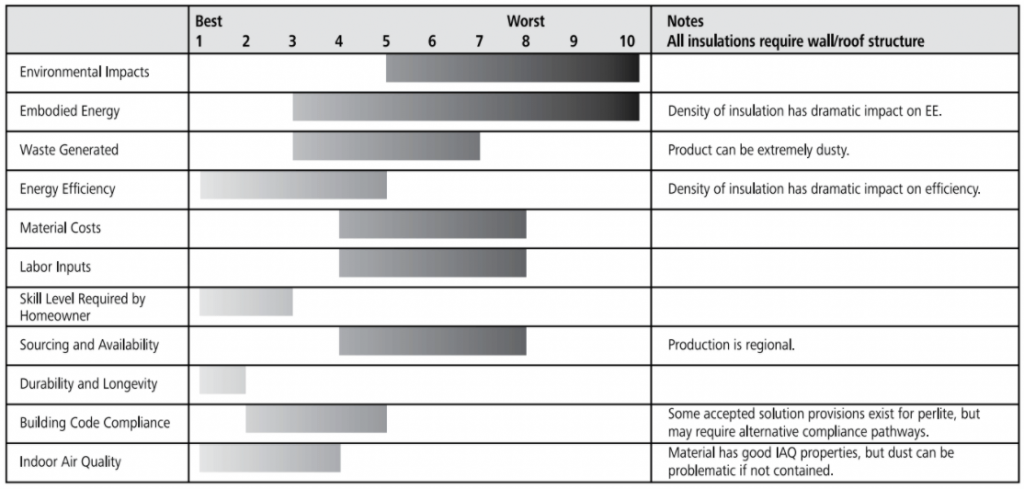

Ratings Chart for Perlite Loose-Fill Insulation

The ratings chart shows comparative performance in each criteria category. Click on the tabs below for detailed analysis of each criteria.

- HOW THE SYSTEM WORKS

- ENVIRONMENTAL IMPACTS

- WASTE

- EMBODIED CARBON

- ENERGY EFFICIENCY

- MATERIAL COSTS

- LABOUR INPUT

- SKILL LEVEL REQUIRED

- SOURCING & AVAILABILITY

- DURABILITY

- CODE COMPLIANCE

- INDOOR AIR QUALITY

- RESOURCES

- FUTURE DEVELOPMENT

Perlite Loose-fill System

Perlite is a volcanic glass quarried in many parts of the world. When the crushed ore is heated it expands from four to twenty times its original volume. It has been dubbed “popcorn rock.” The expanded perlite is graded to a variety of particle sizes. In the forms most suitable for building insulation, the density of the material ranges from 2–9 lb/ft3 (32–150 kg/m3).

The insulation is poured into open wall cavities, attic spaces or onto grade before slab floors are poured. In walls and attics, perlite insulation does not settle after installation. For use under slab floors, the compressive strength of the perlite would have to be deemed suitable to handle live and dead loads.

Most of the perlite used for building insulation is treated with silicon to help prevent water uptake. While the cellular structure of perlite is closed, there is a lot of porous surface area on each piece of perlite that the silicon treatment is intended to reduce.

Environmental Impact Rating

Harvesting — Moderate to High

Perlite is a naturally occurring siliceous rock that is quarried in many parts of the world. Ecosystem impacts will vary with quarrying practice and governing legislation, but open-pit quarries have impacts including habitat destruction and ground and surface water contamination.

Manufacturing — High

The raw perlite ore must be heated to temperatures of 800–1200 ∞C (1500–2200 ∞F) to vaporize the 2–6 percent embedded water in the rock and cause it to expand. This is a fuel-intensive process with impacts including high fossil fuel use and air pollution.

Transportation – Moderate to High

Sample building uses 930 -7,425 kg of perlite:

0.9 – 7 MJ per km by 35 ton truck

Perlite is produced regionally, and transportation impacts will rise with distance traveled.

Installation – Moderate

Perlite is often very dusty, and being lightweight and loose a significant amount of material can be blown from the job site resulting in messy installations.

Waste: moderate

Biodegradable/Compostable — Leftover perlite can be left in the environment.

Recyclable — Plastic packaging materials.

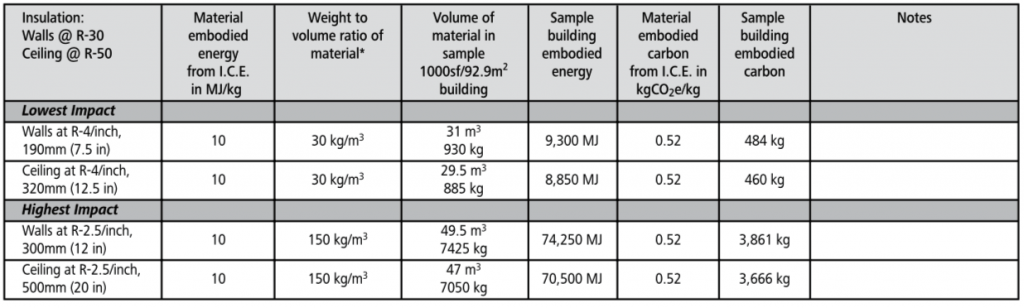

Chart of Embodied energy & carbon

Energy Efficiency: moderate to high

R-values range from 2.5/inch at densities near 150 kg/m3 up to 4.0/inch at 30 kg/m3.

Perlite does not prevent the free movement of air and must therefore be used in conjunction with an air control layer of some kind to prevent unwanted heat loss.

Material costs: moderate to high

Perlite is not a common residential insulation material, and costs can be high depending on sourcing, packaging and distribution.

Labour Input: moderate to High

Perlite is poured from relatively small bags into cavities. The bags are not heavy and the process is very simple as long as the cavity being filled is easily accessible and nothing prevents the free flow of perlite throughout the area to be insulated. Containment must be provided on all sides of the cavity.

Health Warning

Perlite is high in silica dust.

Skill level required for homeowners: Low

Insulating with perlite requires no previous experience or special skills.

Sourcing & availability: moderate to Difficult

Masonry supply outlets often carry perlite for insulating the cores of CMU walls, and this type of perlite would be appropriate for most insulating purposes. In regions where this practice is not common, perlite can be difficult to source.

Durability: High

Perlite is not susceptible to decay or decomposition, and is not affected by the presence of water (other than loss of insulation value). It is fireproof and not a food source for insects or rodents. A long lifespan can be expected.

Code compliance

Code standards exist for the use of perlite as loose-fill insulation in masonry construction, and these standards should be applicable for similar uses in other wall and roof systems. The use of perlite beneath floor slabs may require the approval of a structural engineer.

Indoor air quality: moderate to high

Perlite is often wrongly associated with vermiculite, another type of expanded mineral insulation that can contain asbestos. Perlite does not contain asbestos.

The dust from perlite has high silica content, and is therefore dangerous to breathe during construction. Contained within a wall with an effective air control layer on both sides, this material should not affect indoor air quality, but care must be taken to ensure all cavities are well sealed from the interior space.

Perlite does not support mold growth and is chemically stable.

Resources for further research

n/a

Future development

The concrete industry has long used perlite aggregate in the manufacture of lightweight concrete materials, and the increasing interest in structural/insulated concrete will likely cause an increase in perlite production. Several types of insulation boards also use perlite, and this use is also likely to increase. It is difficult to know if loose-fill perlite will increase in popularity. It has many good characteristics to recommend it, and more energy-efficient buildings are starting to use double-wall systems that are easy to insulate with loose-fill. On-site handling will always remain an issue to overcome, as the material tends to become airborne and spread. At this time, there doesn’t seem to be any trend toward more use of perlite insulation as loose fill.

Tips for successful perlite loose-fill insulation

1. Obtain a perlite product intended for building insulation purposes. Most perlite is produced for agricultural use, and while the two share many similar properties, perlite is properly graded and treated specifically for use as insulation. Agricultural versions may have a lot of fine particles that are not as well suited for thermal resistance and will not be treated to prevent moisture infiltration.

2. Do not install on windy days! Perlite beads are very lightweight and can easily become airborne. Cover insulated areas immediately after installation to prevent the beads from blowing away.