Masonry Heaters

HVAC: MATERIALS ENCYCLOPEDIA

Heat production & delivery

Biomass heat production (wood-fired)

Passive air/radiant delivery system

Hydronic heat delivery available for some systems

Can be used for domestic hot water heating

System components

Burn chamber and ash pan

Masonry chimney with non-linear pathway

Masonry shroud (can be any kind of masonry, including clay)

Air inlet and controls

Cooking oven space (some units)

Water heating coil or tank (some units)

How the system works

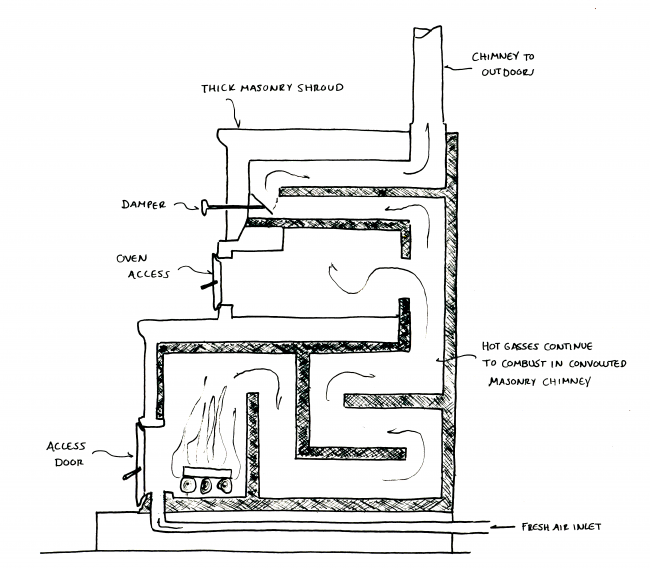

A freestanding unit is placed, usually centrally, in the home. The weight of the unit often requires special foundation considerations for adequate support. The unit has a burn chamber where a fire is lit and burns.

Combustion air is introduced through a manually or mechanically controlled inlet. Ideally, this air enters through a sealed inlet directly from outdoors. Masonry heaters do not use dampers on the air inlet, as the fire is burned at the highest possible temperature, requiring a significant column of air.

Exhaust gasses do not exit directly into a straight chimney, as with woodstoves. Instead, a masonry chimney with a non-linear path receives the gasses. Once the combustion chamber and chimney have become heated, the entire chimney pathway acts as a secondary burn chamber. At full temperature, practically 100 percent of the gasses are combusted within the chimney. These units are not limited in their burn temperatures by any metal components, and can burn at 1200–1800 ∞C (2200–2900 ∞F).

Heat is absorbed by the masonry of the combustion chamber and chimney and radiated to an outer sheathing of masonry separated from the core by an air space. In this way, the interior of the home is not exposed to the very high temperatures, but the majority of the stored heat is slowly released to the room at comfortable temperatures. The outer sheathing can be made from a wide range of materials, from stone or brick to clay or tile. Spent gasses leave the building via a straight run of metal or masonry chimney.

A fire is built in the masonry heater as often as is required to keep the whole unit at a comfortable temperature. The large amount of fuel requires a long time to reach operating temperature, and then takes a long time to cool down. The units are at their most efficient when burning hot, and timing of fires is important to keep the heaters in the proper temperature range. The burn time is usually much shorter than with less efficient woodstoves.

Rare models feature the ability to heat water within the stove. This can contribute to hydronic space heating and/or domestic hot water.

Fuel for woodstoves is manually input directly into the firebox through an opening door, and ash is removed as required.

System output

There are no third-party ratings for masonry heaters, but estimates based on the volume of wood typically burned in an hour of operation range from 10,000–30,000 Btu/hr.

At proper operating temperature, combustion is 100-percent efficient. It will be less than that when starting from cold temperatures.

Environmental impacts: low

Masonry heaters make efficient use of wood fuel, extracting the full heat value and leaving only minute traces of gasses in the atmosphere. See Biomass as a Heat Source sidebar.

Material costs: Moderate to high

Labor input: moderate to high

The assembly of a masonry core and shroud is quite labor intensive. A bigger heater and the addition of features like ovens and water heating jackets will increase labor.

Skill level required for the homeowner

Installation — Difficult. Precast kits make it possible for owners to build a masonry heater, but some degree of experience with masonry work is recommended.

Use — Moderate. Firings must be made on a regular schedule.

Maintenance — Easy to Moderate. Ash removal must be performed regularly.

Sourcing/availability: moderate

Several manufacturers in North America specialize in making precast kits for masonry heater cores, and a small number of masons build units from scratch. Any experienced mason should be able to build a kit unit and a custom shroud.

Code compliance

Masonry heaters are not an accepted solution in any codes in North America. Provisions exist for the construction of masonry fireplaces, which are of quite different construction but present a useful framework. A standard has been developed, ASTM 1602 E–01 “Standard Guide for Construction of Solid Fuel Burning Masonry Heaters,” and this document is helpful for achieving alternative compliance.

Durability: very high

A well-built masonry heater can last for centuries.

Indoor air quality

The movement of cordwood through the home and its storage in the home can introduce large quantities of mold spores, dust and other outdoor allergens. The collection and movement of ash will result in some amount of the material being spread in the air. As the woodstove is opened to feed the fire, combustion gasses and ash will enter the room and this process is repeated many times a day.

The use of wood-burning devices should be accompanied by the use of a good quality active air filtration system if indoor air quality is a priority.

Adequate ventilation is required in any well-sealed home. Whether provided actively or passively, ensure that pre-warmed fresh air is introduced and circulated in the home during seasons when windows are closed.

Future development

Masonry heater technology can be traced back thousands of years, with a variety of approaches having been developed in most northern climates. The advent of commercially produced core kits was a major development over the past couple of decades, allowing homeowners and masons to build heaters that perform well without the potential problems of site-built designs. Combustion technology continues to inform and refine these designs.

The coupling of masonry heater design with pellet fuel systems would combine the benefits of masonry heaters with automatic ignition and feed convenience.

The further integration of water heating and cooking into heater designs will help to offset the high initial costs by absorbing several functions.

The weight and permanence of masonry heaters makes it unlikely that they will ever be a major part of the market, but their efficiency and comfort deserves to win them a larger presence than they currently maintain.

Resilience

It is possible to build and operate a masonry heater in a no- or low-energy scenario. They are the most efficient and practical option for a homeowner with access to fuel stock.

Tips for a successful masonry heater

1. Be sure the masonry heater is “lifestyle appropriate” before deciding to install one. These heaters require an even schedule of firing, and are not suitable for quickly taking the chill off a room. A cold stove can take long hours to reach comfortable temperatures.

2. Foundations must be designed to carry the weight of a masonry heater.

3. Central placement in the home is usually recommended. The mild surface temperature and passive heat delivery are most evenly distributed from the middle of the building.

4. A suitable column of outdoor air should be available to the stove, and must be included in the building plans.

5. The need to bring fuel to the stove and remove ash should be considered when deciding upon placement.

6. Many masonry heaters come as Precast kits, in which a properly designed combustion chamber and chimney are prefabricated and assembled on-site. Follow all installation instructions when using a kit.