Forced Air Furnace

HVAC: MATERIALS ENCYCLOPEDIA

Heat production & delivery

Biomass heat production (wood- and pellet-fired)

Fossil fuel heat production (gas- and oil-fired)

Biofuel heat production (biodiesel- and vegetable oil-fired)

Electric resistance heat production

Forced-air delivery

System components

Combustion chamber (or resistance elements for electric units)

Heat exchanger and plenum

Direct vent (sealed) intake and exhaust (for combustion units)

Circulation fan

Controls as required

How the system works

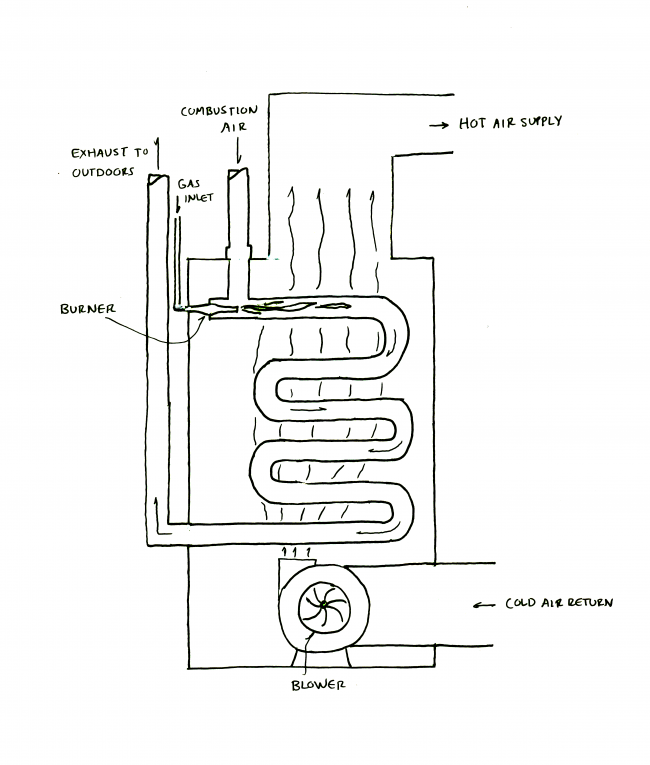

When heat is required, a burner ignites (or electric elements are powered). A heat exchanger plate absorbs heat from the flame/element and transfers it to the air being blown through the plenum.

When heat is required, a burner ignites (or electric elements are powered). A heat exchanger plate absorbs heat from the flame/element and transfers it to the air being blown through the plenum.

The ductwork has both heat supply ducts and cold air return ducts. The cold air return ducts congregate at the plenum, where the air is reheated and forced through the supply ducts to outlets throughout the home. A filter is situated near the plenum to remove dust and allergens as the air is circulated.

System output

Residential furnaces typically have outputs that range from 40,000–150,000 Btu/hr. Efficiency rates range from 89–96 percent.

In most cases, the expressed efficiency is not the “true” thermal efficiency, which could be measured at an ideal steady state and not reflect real world performance. The accepted standard of efficiency is “annual fuel utilization efficiency” (AFUE). The method for determining the AFUE for residential furnaces is the subject of ASHRAE Standard 103. Ensure that rated output for comparison between units is the AFUE.

Environmental impacts: high

The impacts for furnaces are directly linked to the fuel source used to fire the furnace. When considering the impacts of a fuel source, it is important to be as thorough as possible. Calculations for impacts must consider the entire life cycle, from extraction to processing, transportation, combustion and by-products. Effects on habitat, social fabric, geopolitical and financial systems and resilience must be taken into account along with more easily quantifiable (though likely controversial) numerical assessments such as carbon contributions and air pollutants (see Ranking Fuel Sources sidebar).

Material costs: Moderate

Labor input: moderate

Installing a furnace is fairly straightforward, but the ductwork can add a great deal of time and complexity.

Skill level required for the homeowner

Installation — Difficult. Most furnace and ductwork installations require a qualified professional.

Use — Easy.

Maintenance — Easy to Moderate. Monthly inspection of filter. Annual inspection of burner flame (if required).

Sourcing/availability: Easy

Competitive quotes for furnace system designers, suppliers and installers will be available in all regions.

Code compliance

Furnace systems are an accepted solution in all codes. New technologies like pellet and biofuel boilers may require alternative compliance efforts.

Durability: moderate to high

Modern furnaces can last twenty to fifty years, depending on use and maintenance. Manufacturers offer warranties of five to ten years on heat exchangers and pumps.

Indoor air quality

Any combustion device can create IAQ issues, as they consume air and produce exhaust. Modern, code-approved devices have “sealed” combustion, meaning that combustion air is drawn directly from outside and exhausted back to the outside, and usually drawn by a fan to ensure proper flow. There are many possible points of leakage in these systems; be sure to check installations for issues. The combustion chamber is never completely sealed from indoors, and some amount of indoor air will be drawn into the unit.

Solid fuel burning devices will generate ash as a by-product, and in most cases the ash is stored in the unit and will need to be manually emptied. This can introduce a lot of dust into the home. The movement of firewood and, to a lesser degree, pellet fuel will also introduce dust and allergens.

Hydronic delivery systems result in gentle air movement and minimal circulation of dust and allergens.

Forced-air delivery systems can circulate a lot of dust and allergens. Use the best filters possible to help reduce issues.

Adequate ventilation is required in any well-sealed home. Whether provided actively or passively, ensure that pre-warmed fresh air is introduced and circulated in the home during seasons when windows are closed.

Future development

Efficiency levels for furnaces are approaching 100 percent, beyond which there is no further improvement. Refinement of controls and especially variable speed fans will likely lead to some gains for entire systems.

The integration of ventilation systems with furnaces offers an opportunity to make both systems more efficient and improve the air quality in the home.

Resilience

Furnaces can be operated in a low-energy scenario, but the entire system could not be manufactured and installed without significant energy input.

Tips for a successful forced air furnace

1. Be sure the furnace is sized appropriately, based on an accurate heat loss calculation.

2. A variable speed fan can increase efficiency by turning at a speed best suited to the heating requirements, rather than being on or off.

3. Consider integrating a mechanical ventilation system into the ductwork for the furnace, rather than having two separate systems.

4. Keep ductwork within the building enclosure and be sure the ductwork layout is as efficient as possible.

5. Carefully consider the positioning of ductwork outlets. Common practice places outlets blowing upwards beneath windows, but this is not necessary in an airtight, efficient home with high-quality windows. Try to place outlets where they won’t be blocked by furniture, and aimed so they blow horizontally across the floor instead of pumping hot air at the ceiling.

6. Invest in the highest quality filters available for the furnace.

7. Be sure to have the system balanced at commissioning. Fine-tuning the output of each outlet will result in greater comfort and efficiency.