Air Source Heat Pump

HVAC: MATERIALS ENCYCLOPEDIA

Heat production & delivery

Heat pump production

Air delivery (hydronic delivery beginning to be available)

System components

Heat pump (placed outside the home)

Heat exchanger/plenum (inside the home)

Air or hydronic delivery system

Controls as required

How the system works

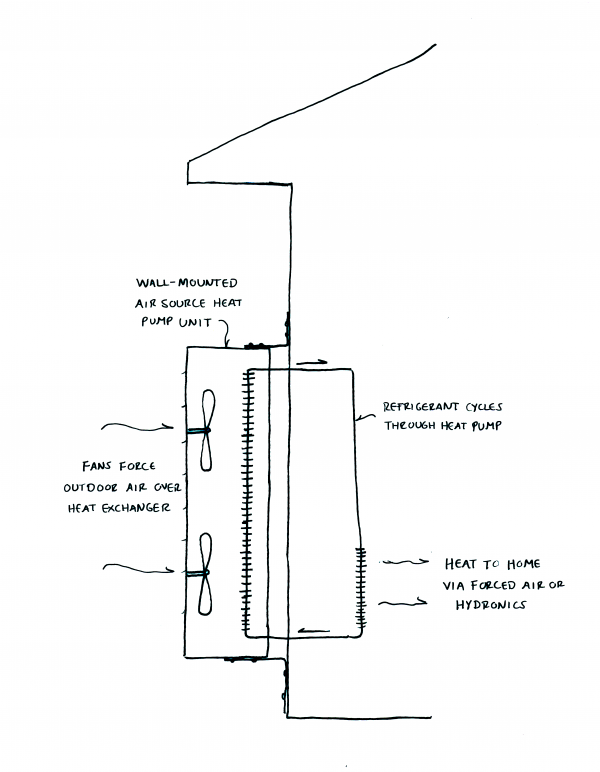

A heat pump unit is mounted outside the home. This includes one or more large fans to move outdoor air over the heat exchanger coil, to transfer air temperature to the refrigerant. The condenser/heat exchanger is contained in a plenum in the ductwork of the home, where the heat is delivered via forced air. The cycle is reversed to provide cooling in the summer.

A subset of ASHPs called ductless mini-splits operate on the same heat pump principle, with outdoor pumps absorbing heat from the ambient air. However, instead of supplying heat to a plenum in a central forced-air system, they send the heated refrigerant to one or more (up to six, for some models) independent condenser “heads” or cassettes placed in a room; room air is then blown over the heated refrigerant. This option eliminates the need for central ductwork and can provide well-distributed heat in an energy-efficient home for a lower cost.

System output

ASHPs and ductless mini-splits can be purchased with output ranging from 9,000 – 40,000 Btu/hour (0.75–3 ton).

Most systems will advertise a coefficient of performance (COP) from 3.0–4.0. Due to the highly variable temperature differences in outdoor air, this figure is usually a best-case scenario. Reviewing a graph of COP based on outdoor temperature will usually show a COP ranging from 1.0 (the same as electric resistance heating) at the coldest outdoor temperatures up to 3.0–4.0 in more moderate temperatures.

Environmental impacts: moderate to high

There are benefits to the efficiencies enjoyed by ASHPs, reducing overall energy use and emissions compared to combustion and electric resistance devices. If the electrical energy is supplied by renewable sources, the systems can be emission free.

The refrigerants used in the heat pumps are significant greenhouse gasses, with impacts much higher (as much as hundred times) than that of CO2. The most dangerous refrigerants have been or are in the process of being phased out, but the current compounds still have significant impacts during manufacturing, commissioning, repair and if or when leaks occur in the system. Currently, refrigerants like R-410A are touted as being environmentally friendly, but only compared to the extremely unfriendly versions they replace.

Material costs: moderate to high

ASHP units vary in cost by output and by useful operating temperature range. Less expensive models will tend to have lower output and function in a narrower temperature range.

Labor input: moderate

The installation of ASHP units is straightforward. For ducted systems, the ductwork will require more labor than the ASHP.

Skill level required for the homeowner

Installation — Difficult. Only licensed professionals can perform an ASHP installation, due to the need to charge the system with refrigerant.

Use — Easy.

Maintenance — Easy to Moderate. Units are typically easily accessible for inspection and maintenance.

Sourcing/availability: Easy to moderate

There are sufficient numbers of ASHP designers, suppliers and installers that competitive quotes should be available in most regions.

Code compliance

ASHPs are an accepted solution in many codes, though regions in colder climates may not yet consider them an acceptable solution without backup heat. In these cases, a properly designed system based on an accurate heat loss calculation should be accepted as an alternative solution.

Durability: moderate

ASHPs have shown themselves to be relatively durable within their expected service life of fifteen to twenty years. Many manufacturers warranty compressors for five to ten years.

Indoor air quality

An ASHP will not have any direct effect on IAQ, except in the rare case of a refrigerant leak.

Forced-air delivery systems can circulate a lot of dust and allergens. Use the best filters possible to help reduce issues.

Adequate ventilation is required in any well-sealed home. Whether provided actively or passively, ensure that pre-warmed fresh air is introduced and circulated in the home during seasons when windows are closed.

Future development

Rapid and significant improvements have been made to ASHPs for cold climates over the past few years, and while dramatic changes are unlikely, there will be continued gains in efficiency and lowering of costs.

The most important development from an environmental perspective would be a move to more benign refrigerants. CO2 is being used as a refrigerant in some new units, and other natural compounds are being researched. All natural refrigerants require design changes to heat pumps that currently raise electrical demand and have durability issues, but growing pressure to phase out all damaging refrigerants will likely lead to positive developments.

ASHPs designed to supply heat for hydronic systems are nearing widespread introduction, opening the technology to homeowners who wish to combine this means of heat production with hydronic delivery.

Resilience

There is no way to build, install or operate a GSHP in a low- or no-energy scenario.

Tips for a successful air source heat pump

1. The fans and compressor in the outdoor portion of the heat pump can be quite noisy. Be sure to locate units where the sound will not disturb occupants or neighbours.

2. In locations with very low winter temperatures, be sure the ASHP can produce enough heat at those temperatures; if it can’t, a back-up heat source will be required.

3. When using ducted systems, ensure that the ductwork design is very efficient, as temperatures from ASHPs are lower than those of combustion systems.