Linoleum

Flooring: MATERIALS ENCYcLOPEDIA

Applications for this system

Finish flooring. Can be applied directly to wooden sub-floors and wet-poured floors with adhesive, or over wooden and wet-poured floors in laminate-style planks or tiles.

Basic materials

Oxidized linseed oil (pressed from flax seed) or other polymerizing oil (soya bean or menhaden oil)

Resin (often pine resin, or ester or kauri gum)

Calcium carbonate (ground limestone)

Wood powder (ground sawdust) and/or cork powder

Pigment for coloring

Jute or other natural fiber for backing

Laminated wood or fiberboard for backing, when applicable

Adhesive, when applicable

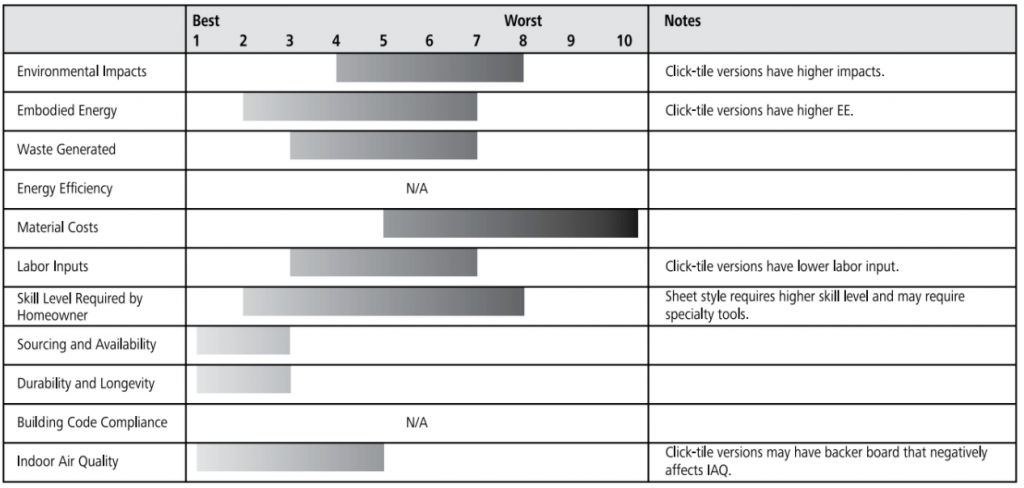

Ratings Chart for Linoleum flooring

The ratings chart shows comparative performance in each criteria category. Click on the tabs below for detailed analysis of each criteria.

- HOW THE SYSTEM WORKS

- ENVIRONMENTAL IMPACTS

- WASTE

- EMBODIED CARBON

- ENERGY EFFICIENCY

- MATERIAL COSTS

- LABOUR INPUT

- SKILL LEVEL REQUIRED

- SOURCING & AVAILABILITY

- DURABILITY

- CODE COMPLIANCE

- INDOOR AIR QUALITY

- RESOURCES

- FUTURE DEVELOPMENT

Linoleum floor System

Linoleum glue is formed by blending oxidized linseed oil and pine resin, into which powered limestone, wood and cork are mixed, along with any desired pigment. This mixture is added over a wide-woven natural fabric, such as jute or burlap backer. The linoleum is then cured in a kiln or drying room for a number of days to complete the polymerization of the oils and harden the mixture.

Rolls of sheet material or individual tiles are cut from the cured linoleum. This material can be applied directly to sub-floors by means of an adhesive.

Tiles or planks of linoleum may also be adhered to laminate wood or fiberboard backing to make a “click-down” form of interlocking tiles.

Environmental Impact Rating

Harvesting — Low to Moderate

There are many components to linoleum, but none are high intensity at the harvesting stage. The oils come from agricultural production, and will carry whatever impacts created by the style of farming used, which can include pesticide and herbicide use, groundwater contamination and destruction of habitat for farming. Oil harvesting and pressing is not considered a high-impact process. Pine resin can be harvested sustainably by tapping appropriate pine trees and collecting the raw resin, and is not generally considered a high-impact process. The wood and cork dust is typically derived from waste material from other manufacturing processes, keeping it from burning or landfill. Calcium carbonate, used in small quantities, is harvested from limestone quarries. Impacts include groundwater disruption and contamination. Jute is made from the fibers of plants in the genus Corchorus. This type of plant is rain-fed in monsoon areas and typically needs little or no herbicides, pesticides or fertilizer, and is considered a low-impact material to harvest.

Harvesting the ingredients for chemical adhesives can have impacts including air and water pollution, habitat destruction and greenhouse gas emissions.

Manufacturing — Moderate

Creating linoleum is a multi-stage process, but it is not highly energy intensive. The largest energy inputs are used to heat the oil early in the process and again to provide warm drying rooms for the product to cure. VOC emissions are released during manufacture, but are typically controlled against release to the atmosphere.

Transportation — High

Sample building uses 272.5 – 741.6 kg of linoleum flooring:

0.4 – 1.1 MJ per km by 15 ton truck

0.25 – 0.7 MJ per km by 35 ton truck

0.04 – 0.12 MJ per km by ocean freight

The ingredients for linoleum come from different parts of the world and must be transported to the factory, incurring high transportation impacts. The only commercial linoleum producers are based in Europe, and all North American linoleum is imported, incurring a second round of transportation impacts.

Installation — Moderate

The welding of seams for sheet-style installations releases VOCs as the linoleum welding rods are melted. Chemical adhesives will also off-gas during construction.

Waste: moderate to high

Compostable — Sheet and tile linoleum offcuts. In theory, linoleum is compostable, as all the ingredients are biodegradable. However, it will take a long time for the polymerized oil to break down in the environment and it may not be feasible to send the material to compost. Quantities can vary from low to high, depending on the installation.

Landfill — Sheet and tile linoleum offcuts. If the material cannot be sent to an appropriate composting facility, they will likely end up in landfill. Quantities can vary from low to high, depending on the installation.

Click-down linoleum offcuts. The composite of linoleum and wood-fiber backer will not be easily separable and is typically sent to landfill. Quantities can vary from low to high, depending on the installation.

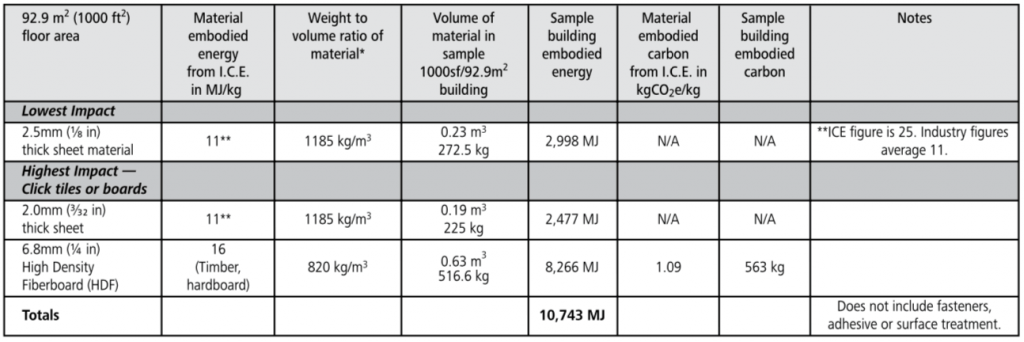

Chart of Embodied energy & carbon

Energy Efficiency: n/a

Linoleum flooring will have no impact on energy efficiency.

Material costs: moderate to high

Natural linoleum occupies a small percentage of the market and is typically aimed at high-end uses, with attendant high costs.

Labour Input: moderate

Linoleum flooring requires a similar amount of labor as other flooring options. Click-down versions are at the low end and sheet-style at the higher end.

Skill level required for homeowners

Preparation of sub-floor — Easy

Click-down versions will require little to no preparation, while adhesive versions may require a surface preparation that is typically rolled or brushed onto the sub-floor.

Installation of floor — Easy to Difficult

Click-down versions are straightforward to install, and require simple layout and saw-cutting skills. Adhesive tiles are similarly easy, with cuts made with a sharp blade and tiles laid directly onto the floor. Sheet-style installations are difficult, as it takes practice to handle and cut large rolls to size. Adhesive needs to be applied evenly to a large area of floor and the sheet laid carefully to avoid bubbling. Welding seams requires special tools and training.

Finishing of floor — Easy

Most linoleum products are pre-finished and will require no additional work.

Sourcing & availability: Easy

Linoleum is becoming more widely available, with versions available at many building supply outlets and specialty flooring shops.

Durability: High

Old linoleum has been known to last thirty to fifty years, and estimates for modern versions range from fifteen to fifty. Proper maintenance of linoleum is a key part of longevity, with periodic application of a sealing product recommended by the manufacturer helping to extend lifespan. Most modern linoleum is designed for and installed in high-traffic public buildings, and will do well in residential scenarios with lower wear.

Code compliance

Most codes are not prescriptive when it comes to finished flooring materials, as long as the sub-floor has been constructed to code and in a manner intended to support the dead load imposed by the flooring.

Indoor air quality: high

Linoleum itself is quite inert and should have little to no detrimental effect on IAQ. Some people may have sensitivities to linseed oil and may want to see if exposure to linoleum has an effect on them.

The adhesives used for some installations often carry serious warnings about the inhalation of vapors, with potential cancer-causing and birth defect-causing effects. There may be residual and lingering off-gassing from these products. Be sure to select adhesives that have been formulated to have the least possible impact on IAQ, preferably those with third-party certification.

Resources for further research

The Complete Guide to Flooring. Minneapolis, MN: Creative Publishing International, 2010. Print.

Future development

The basic recipe for linoleum was developed in the 1800s, and has changed very little. Linoleum has seen a real resurgence over the past decade, as this once-popular type of flooring has made a comeback largely due to its generally strong environmental characteristics. It would be ideal if demand led to the re-establishment of North American production facilities, reducing the need to import all linoleum products from Europe.

Development is likely to lead to simpler installation methods and less toxic adhesive options. The use of linoleum in public buildings, especially hospitals and schools, is likely to raise its profile among homeowners and continue to grow demand.

Tips for a successful linoleum floor

1. Sheet-style, tile or click-down options require different installation procedures. Be sure you know which kind of linoleum you’d like to install at the planning stage, as final floor thickness and appearance vary considerably between the options. Sheet linoleum can cover large areas with no seams, or can be cut into patterns that would be difficult to match with any other flooring style. Adhesive tiles and click-down will create patterns similar to other tile or plank floors.

2. Sheet-style linoleum installations should be done by a professional. Tools and techniques are quite specific, in particular the welding of seams, and typically not appropriate for homeowners.

3. Linoleum that requires adhesive connection may require special treatment and glues for different sub-floor types.

4. Linoleum off all types will come with manufacturer’s instructions for installation, which should be followed carefully.