hemp batt

Insulation: MATERIALS ENCYcLOPEDIA

Applications for this system

Wall insulation

Ceiling insulation

Raised floor insulation

Basic materials

Hemp fibre

Recycled cotton and/or polyester fiber

Boron (fire retardant)

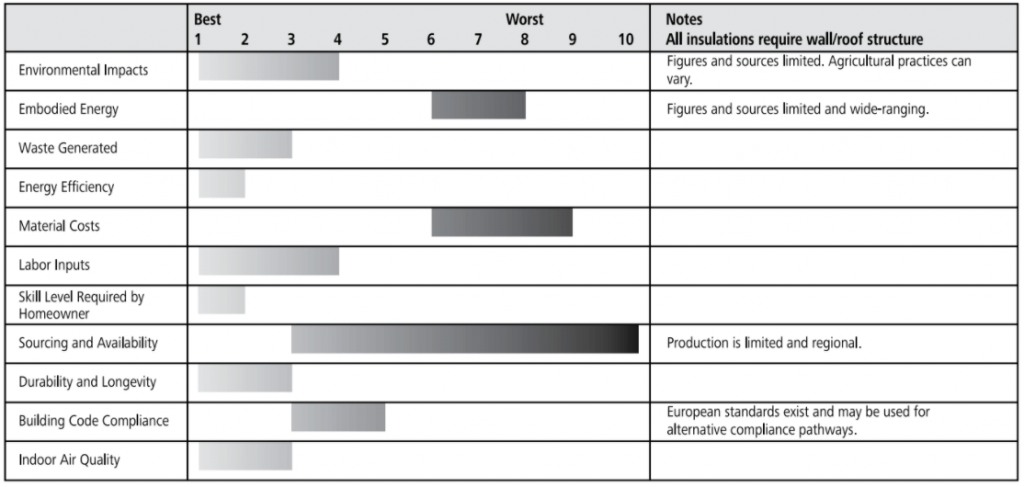

Ratings Chart for Hemp Batt insulation

The ratings chart shows comparative performance in each criteria category. Click on the tabs below for detailed analysis of each criteria.

- HOW THE SYSTEM WORKS

- ENVIRONMENTAL IMPACTS

- WASTE

- EMBODIED CARBON

- ENERGY EFFICIENCY

- MATERIAL COSTS

- LABOUR INPUT

- SKILL LEVEL REQUIRED

- SOURCING & AVAILABILITY

- DURABILITY

- CODE COMPLIANCE

- INDOOR AIR QUALITY

- RESOURCES

- FUTURE DEVELOPMENT

Hemp Batt System

Hemp fiber, sometimes combined with cotton or polyester fiber, is spun into insulation batts in a range of sizes to fit common stud cavity dimensions.

Environmental Impact Rating

Harvesting — Low

A fast-growing bio-fiber plant, hemp can have high production yields from less-than-ideal soils. Little in the way of herbicides or pesticides is required for hemp production, though fertilizer use can be high.

Manufacturing — Low

Processing energy input is lower than many other insulation products. Additional fibers (cotton or polyester) are typically sourced from waste streams.

Transportation — Low to High

Sample building uses 1,320 kg of hemp batt:

2 MJ per km by 15 ton truck

1.25 MJ per km by 35 ton truck

0.2 MJ per km by ocean freighter

Production of hemp batts in North America is limited and there is usually a lot of transportation required to acquire the material. Battsbatts are often imported from Europe. Impacts accrue with distance traveled, though it is a lightweight material.

Installation – Negligible

Waste: Low

Recyclable — Plastic packaging.

Landfill — Insulation offcuts. The addition of polyester fibers in most brands prevents the material from being fully biodegradable.

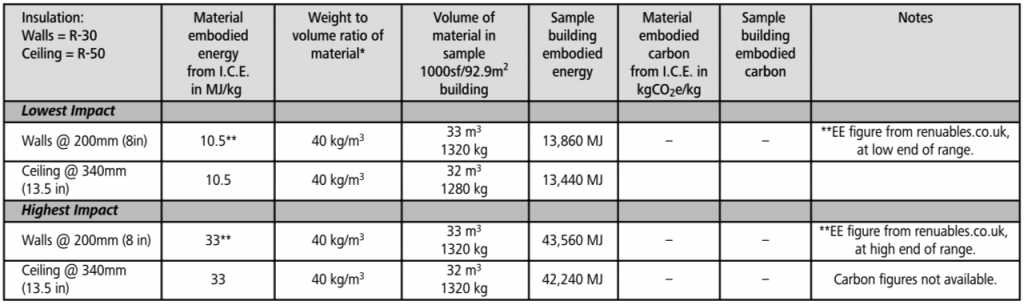

Chart of Embodied energy & carbon

Energy Efficiency: high

R-value: 3.7/inch

Hemp batts have similar thermal resistance as other forms of batt insulation. As with any batt, proper installation is key to real thermal performance. Gaps and voids in the insulation near framing members, the top of the wall and around obstacles like electrical boxes will reduce overall thermal performance.

Material costs: high

Limited availability keeps costs high, though the material has the potential to be cost competitive if large scale production were started in North America.

Labour Input: low to moderate

Installation of hemp batts will be comparable to other batt materials. Hemp fibers are very strong, and cutting the batts can be more difficult than other insulations, which adds labour time.

Skill level required for homeowners: Low

Batt insulation can be successfully installed with very little experience, as long as care is taken to ensure tight fits in all cavities and to avoid voids or gaps.

Sourcing & availability: moderate to Difficult

Hemp batts are not widely available in North America. A few small Canadian producers augment a supply that is otherwise currently imported from Europe. The products are not available at most building supply stores and require user sourcing.

Durability: High

Hemp is naturally resistant to insects and rodents. Kept reasonably dry, it offers a long lifespan.

Code compliance

Producers of hemp batts have certified their products to applicable code standards. Hemp batts imported into the US from Canada or Europe may not have met all the standards required by local codes, but it should be possible to show equivalency.

Indoor air quality: high

Hemp batts have no glues or binders that off-gas and the fire retardants are usually boron-based and do not have hazardous side effects. Hemp batts could provide a food source for mold growth, but kept reasonably dry they should not be an impediment to good indoor air quality.

Resources for further research

n/a

Future development

Hemp products in North America are unlikely to reach a wider market until US restrictions against the growing of industrial hemp are changed. Until then, imported hemp products will continue to have higher prices and poor distribution. The potential exists for this type of product to be produced regionally in many parts of the continent and for prices and availability to be competitive with all other insulation materials.

Tips for successful hemp batt insulation

Batt installations must be free of voids and gaps to achieve maximum thermal performance. Manufacturers will provide specifications for installation.