Engineered Wood

Flooring: MATERIALS ENCYcLOPEDIA

Applications for this system

Finished flooring. Can be applied on wooden sub-floors. May require strapping or sheathing if applied over wet-poured floors.

Basic materials

Hardwood or softwood veneer

Plywood base

Finishing product

Underlayment layer (if required)

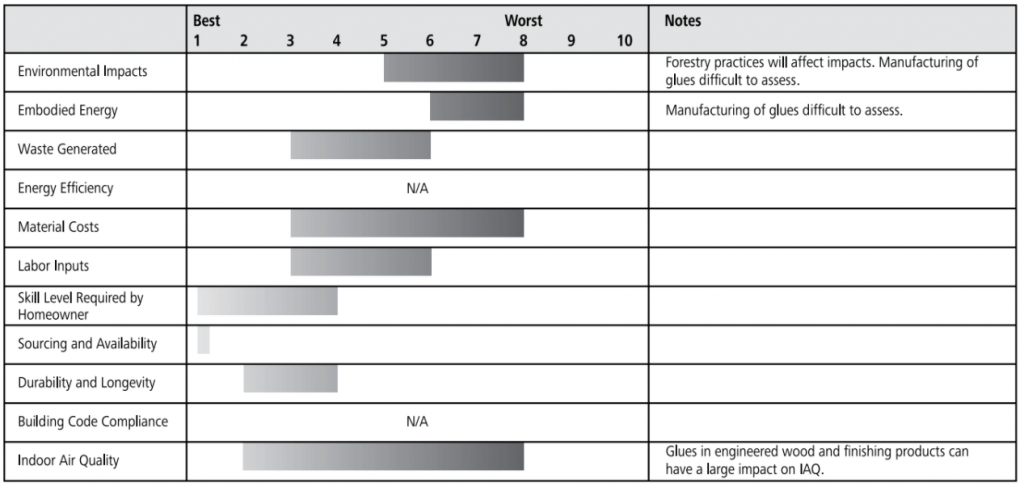

Ratings Chart for Engineered wood flooring

The ratings chart shows comparative performance in each criteria category. Click on the tabs below for detailed analysis of each criteria.

- HOW THE SYSTEM WORKS

- ENVIRONMENTAL IMPACTS

- WASTE

- EMBODIED CARBON

- ENERGY EFFICIENCY

- MATERIAL COSTS

- LABOUR INPUT

- SKILL LEVEL REQUIRED

- SOURCING & AVAILABILITY

- DURABILITY

- CODE COMPLIANCE

- INDOOR AIR QUALITY

- RESOURCES

- FUTURE DEVELOPMENT

Engineered wood System

A veneer layer of the desired type of wood for the surface of the floor is bonded to a plywood base with a tongue-and-groove or other interlocking edge pattern milled into it. This system has two advantages over solid wood flooring: it allows the value and beauty of a particular wood to be the visible element of the floor without requiring the use of valuable species of wood for the entire depth of the floor; and the plywood base is much less susceptible to expansion, contraction and fit issues. The drawback is higher processing energy input and the use of glues between the plies that are likely to contain toxic chemicals unless sourced to minimize or avoid chemical exposure.

Underlayment material may be required for some products. Be sure to investigate the costs and environmental impacts of this part of the system if it is an integral part of the chosen flooring.

Environmental Impact Rating

Harvesting — Low to High

Appropriate sourcing for both the veneer and the base plies will determine the harvesting impact. Using third-party certified products will help to minimize impacts.

In some cases, engineered flooring is a means to make exotic hardwoods more affordable, using just a thin veneer of the expensive wood over a base of less expensive wood. Avoid exotic species that may be having large harvesting impacts in other parts of the world, and be especially aware of products that claim to be third-party certified without ensuring that the exotic wood is also certified.

Manufacturing — Moderate to High

Making an engineered wood floor is similar to manufacturing plywood. Veneer sheets are peeled from raw logs and glued together (usually with 2, 3 or 5 plies) to form the floor planks. Some type of interlocking connection is milled into the edges of the planks. Modern, efficient plywood factories have made strides to minimize waste, water use and effluent discharge, while older plants can be major sources of pollution.

Transportation — Moderate to High

Sample building uses 885 kg of engineered wood flooring:

1.3 MJ per km by 15 ton truck

0.8 MJ per km by 35 ton truck

Some engineered wood plants are located close to wood sources, while others must import wood over long distances. Some plants do all the work required to make the flooring in-house, while others will import veneer sheets, sometimes over long distances. Exotic hardwood products will usually involve shipping either logs or veneer over long distances.

Installation — Low

Waste: moderate

Recyclable — Metal fasteners. Quantities will be negligible. Boxes and packaging. Quantities will be moderate to high.

Landfill — Flooring offcuts. Quantities will be low to high, depending on the requirements of the installation. Underlayment offcuts. Quantities will be low to high, depending on the requirements of the installation.

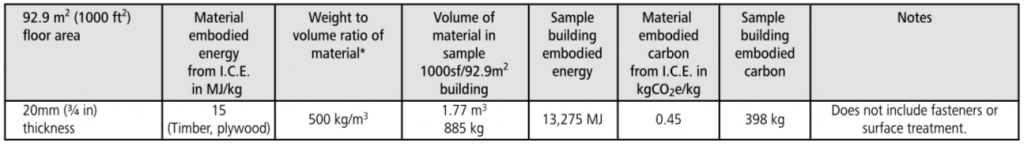

Chart of Embodied energy & carbon

Energy Efficiency: n/a

Engineered wood flooring will have no impact on energy efficiency.

Material costs: Low to high

Engineered wood flooring is a large product category with a wide range of price points.

Labour Input: moderate to High

Some types of engineered wood flooring are designed to “float,” with no need to attach with nails or staples, and these will be among the fastest floors to install. Products that require fastening will be comparable with other types of wood flooring. Engineered wood flooring is typically pre-finished.

Skill level required for homeowners

Preparation of sub-floor — Easy

Installation of floor — Easy to Moderate

A homeowner with the carpentry skills to build a wooden sub-floor structure will be able to install engineered wood flooring. Some installations require a pneumatic nailer, others are “click-down” systems requiring no fastening.

Finishing of floor — Easy

Pre-finished floors require no effort.

Sourcing & availability: Easy

Engineered wood floors are widely available through building material supply outlets and specialty flooring shops. It will take more effort to source third-party certified wood products and glues.

Durability: High

The quality of the glue used to bond the plies together will be the determining factor of longevity, as the wood itself will be long-lasting. The surface finish will also have a large impact on durability.

Code compliance

Most codes are not prescriptive when it comes to finished flooring materials, as long as the sub-floor has been constructed to code and in a manner intended to support the dead load imposed by the flooring.

Indoor air quality: moderate

The wood content in engineered flooring is unlikely to have a negative impact on IAQ, though certain wood species can be allergens for some people. The biggest issue will be the glue used between the plies and the surface treatment product. It is possible to find engineered flooring with Greenguard or similar certification, to ensure minimal impacts.

Resources for further research

Jeffries, Dennis. The Flooring Handbook: The Complete Guide to Choosing and Installing Floors. Toronto, ON: Firefly, 2004. Print.

Future development

The use of third-party certified wood, glues and finishes is likely to increase with greater consumer demand for eco-friendly materials.

Tips for a successful engineered wood floor

Engineered flooring products are proprietary, and will be supplied with manufacturer’s installation instructions.