Solar Hydronic Heating

HVAC: MATERIALS ENCYcLOPEDIA

Heat production & delivery

Solar heat production

Active or passive heat transfer

Hydronic or forced-air delivery

Can be used for domestic hot water heating

System components

Solar thermal collector (flat plate or evacuated tube)

Circulation pump and controls

Storage vessel

Heat exchanger for delivery system

How the system works

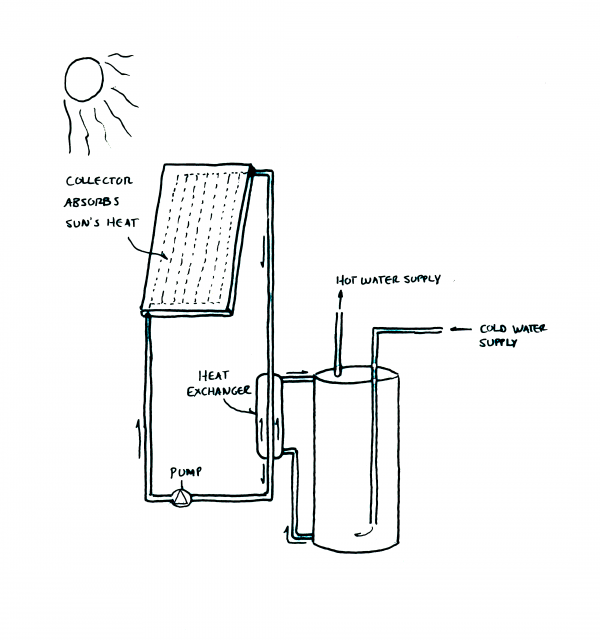

The sun’s energy is gathered in the collector, a system of tubing with a solid connection to a flat metal collector plate or fin with a large surface area. The absorbed heat is then transferred to the hydronic fluid, which is pumped (or sometimes moved by convection alone) to a storage vessel, where it deposits its heat via a heat exchanger. A thermostatically controlled pump circulates the hot fluid in the tank directly to the delivery system or through a second heat exchanger.

The sun’s energy is gathered in the collector, a system of tubing with a solid connection to a flat metal collector plate or fin with a large surface area. The absorbed heat is then transferred to the hydronic fluid, which is pumped (or sometimes moved by convection alone) to a storage vessel, where it deposits its heat via a heat exchanger. A thermostatically controlled pump circulates the hot fluid in the tank directly to the delivery system or through a second heat exchanger.

There are two types of collectors: flat plate and evacuated tube. Each has advantages and disadvantages, and they should be compared carefully to ensure the choice best suits the needs of the particular system.

There are numerous configurations for such systems, including closed loop, drain back and thermosyphon options. Different types of storage tanks and heat exchangers also exist.

Solar energy is stored in an insulated tank or vessel, allowing for use of the heat when required, and not only when the sun is shining. Tank capacity and insulation levels must be designed to provide an adequate storage-to-production ratio so that heat is available when required.

A careful design process must be used to determine how much heat can be reliably delivered via a solar hydronic system. This is the “solar fraction,” which can range from 100 percent in some climates to as low as 25 percent in others. The cost-effectiveness of the system must be compared to the solar fraction and the cost of backup or complementary heating.

Solar hydronic heating systems will overproduce heat during the summer months. If there is no adequate “dump” for this heat, they will need to be drained and/or shuttered in the warmer months.

System output

A typical solar thermal collector is rated at 20,000 – 50,000 Btu per square foot of collector per day. The lower figure corresponds to cloudy days and the higher figure to sunny days. Actual outputs are dependent on collector type, solar angle and exposure. Proper estimates can be prepared for particular locations to help with system design.

Environmental impacts: low

Solar hydronic systems have very minimal impacts, with no extraction, transportation, delivery, emissions or by-products from the fuel source. Electrical consumption for pumps and controls is very low, and can be affordably supplied by on-site photovoltaic (PV) panels.

Material costs: Moderate to high

Type of collector and the components used in the balance of the system will affect price.

Labor input: high

Installing a solar hydronic system involves assembling and connecting numerous separate components, including collectors, pumps, heat exchangers, tanks and controls, and filling and bleeding at least two closed hydronic loops. The heat delivery system also needs to be installed and connected to the solar heat supply. Commissioning the system may require revisiting several times to fine-tune all the various elements.

Skill level required for the homeowner

Installation — Difficult. Construction, plumbing and electrical skills and tools are required. Experience with heating systems and solar hydronics is recommended.

Use — Easy. If properly installed and commissioned, the system should run automatically. A power failure during a sunny period may require recommissioning.

Maintenance — Moderate to Difficult. The pH level of the antifreeze solution in the solar system needs annual testing, and it is wise to inspect the entire system at the same time.

Sourcing/availability: Easy

Every major component of a solar hydronic heating system is available from commercial suppliers, but there are few off-the-shelf systems that include all components and connections. Collectors, pumps and controls can be purchased directly from manufacturers or solar specialty distributors, who may also sell tanks, heat exchangers and controls. The balance of the system can be sourced from plumbing supply outlets.

Code compliance

Solar hydronic heating is not an accepted solution in most codes. It is likely to be accepted as an alternative solution if a licensed professional completes the design and any expected shortfall in heat output is addressed with a code-compliant backup system.

Durability: low to moderate

The collectors, tanks and heat exchangers are all simple pieces of equipment with no moving parts, and will be very durable. Circulating pumps and controls have an expected lifespan of five to fifteen years. Hydronic fluid has a limited lifespan of about five years.

Indoor air quality: High

Hydronic heat delivery lends itself well to good IAQ, as air flow and convection currents in the building are slower and gentler, moving less dust and allergens. There are no combustion products with solar heating, removing another source of irritants.

Adequate ventilation is required in any well-sealed home. Whether provided actively or passively, ensure that pre-warmed fresh air is introduced and circulated in the home during seasons when windows are closed.

Future development

More energy-efficient homes and better components are making solar hydronic systems more practical, by raising the solar fraction so it can be a significant contributor to the overall heating system. The rising cost of fuel can make the investment in a reasonably high solar fraction system a good financial decision.

The development of commercially packaged, integrated systems will greatly expand the market for solar hydronic heating. The current need to blend the expertise of solar installers, plumbers and heating technicians to create a custom system inhibits uptake. A plug-and-play approach designed for a particular climate zone would lower costs and increase reliability.

The rising cost of fuel is going to make a technology that greatly reduces or even eliminates future fuel costs more and more desirable.

Resilience

A simple solar hydronic heating system can be assembled by an owner from readily available used materials, and be designed and built in a low-energy manner. The system may lack the refined controls of a commercially produced installation, but it will successfully provide useful, fuel-free heat.

Tips for successful solar hydronic heating

1. Careful system sizing will determine the amount of collector area required. The collectors must be given a south-facing position on the building (usually on the roof, but sometimes on walls) or on the site close to the building. Roof- or wall-mounted systems must account for the collector weight and wind uplift forces.

2. Solar hydronic systems are quite complex, and require temperature and pressure relief valves and air release valves in specific locations and properly positioned drain and fill points for the fluid to ensure proper function and maintenance.

3. Consider using photovoltaic (PV) panels to provide power to pumps and controls, as they will be producing electricity when the sun is shining and the system requires power. Interruptions in power supply can cause the system to fail and need to be refilled.

4. Creating suitable plumbing chases in the home during construction will make it simpler to run pipes to the solar collector during installation.

5. Try to keep the system as simple as possible. It is possible to end up with multiple heat exchangers, thermostats, pumps and valves, all of which are potential maintenance issues.