Cork

Flooring: MATERIALS ENCYcLOPEDIA

Applications for this system

Finished flooring. Can be applied on wooden sub-floors. May require strapping or sheathing if applied on wet-poured floors.

Basic materials

Cork (bark layer from cork oak tree)

Wood fiber base (for some products)

Adhesive (for some products)

Surface finish

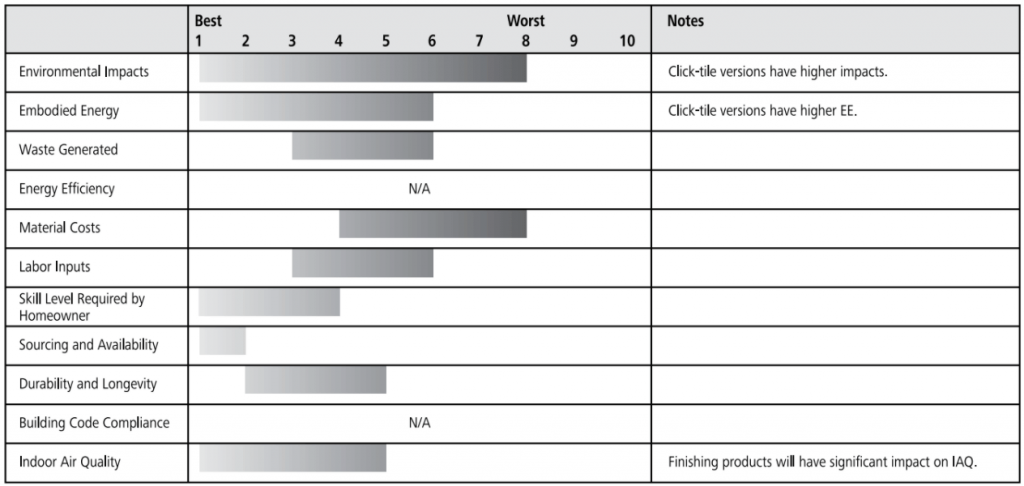

Ratings Chart for Cork flooring

The ratings chart shows comparative performance in each criteria category. Click on the tabs below for detailed analysis of each criteria.

- HOW THE SYSTEM WORKS

- ENVIRONMENTAL IMPACTS

- WASTE

- EMBODIED CARBON

- ENERGY EFFICIENCY

- MATERIAL COSTS

- LABOUR INPUT

- SKILL LEVEL REQUIRED

- SOURCING & AVAILABILITY

- DURABILITY

- CODE COMPLIANCE

- INDOOR AIR QUALITY

- RESOURCES

- FUTURE DEVELOPMENT

cork floor System

The bark of the cork oak tree is harvested (on cycles of seven to twelve years) and air-dried into sheets. Wine corks are punched from the sheets, and the remainder is ground, boiled and formed with adhesives into sheets for cork flooring. Some flooring types use cork sheets that are directly adhered to the sub-floor, while some adhere the cork sheets to a wood fiber backer that forms interlocking planks or tiles. Some forms of interlocking cork require nails or staples to fasten them, while others operate as a floating floor.

Environmental Impact Rating

Harvesting — Low to Moderate

Cork is harvested in a sustainable manner, with the same trees bearing a crop of new bark every seven to twelve years. The harvesting work is still largely done by hand, with little to no impact on the land, water and air.

Cork is made into sheets using binders. The binders can be based on natural resins (like pine resin) that are relatively low-impact in harvesting, but can also be chemical binders such as urea melamine and phenol formaldehyde, which have higher impacts.

Manufacturing — Low to Moderate

Flooring cork is made from the leftover material from bottle stopper manufacturing. Some manufacturers claim that all cork is “recycled” from industrial waste, but the volume of cork used for flooring is equivalent to that used for bottle stoppers and manufacturers do not see the leftover cork as waste but plan equally for its use as flooring and other products. The cork is boiled during processing, which is a relatively high-energy operation, using a lot of water that becomes contaminated. The remainder of the manufacturing process, including grinding and forming sheets with adhesives, is relatively low-energy.

The manufacturing of the adhesives used to bind cork will often involve petrochemicals and will carry high impacts, including air and water pollution and habitat destruction. These adhesives are used in fairly small quantities.

A small amount of cork flooring is made from recycled bottle stoppers, reducing the initial processing impacts of virgin cork.

Transportation — Low to High

Sample building uses 105 – 622.2 kg of cork flooring:

0.15 – 0.9 MJ per km by 15 ton truck

0.1 – 0.6 MJ per km by 35 ton truck

0.02 – 0.1 MJ per km by ocean freight

Cork is only grown around the Mediterranean region and the vast majority of cork flooring is manufactured in that region, keeping initial transportation impacts low. However, cork flooring used in North America must be shipped from this region, carrying high levels of impact.

Installation — Negligible

Waste: moderate

Compostable — In theory, cork is compostable, though the adhesives binding it may not break down and/or leave chemical traces in compost. Most cork flooring is adhered to a wood composite backer and the combined product is not compostable.

Recyclable — Packaging. Quantities can be high, as flooring is often boxed in cardboard and wrapped in plastic in fairly small bundles.

Landfill — Cork flooring offcuts. Quantities can be low to high, depending on the requirements of the installation.

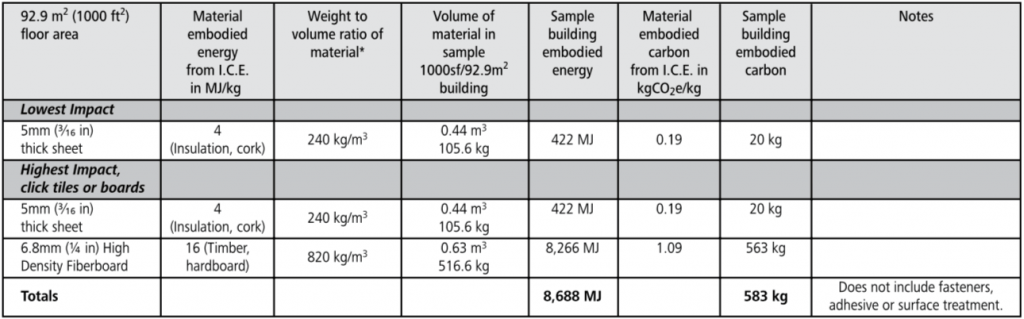

Chart of Embodied energy & carbon

Energy Efficiency: n/a

While cork has the highest R-value of all the flooring products in this book, at approximately R-3 per inch, the actual thickness of the cork component of the flooring is usually 0–10 mm (0–3/8 inch), so it will only be adding ~R-1, which is negligible.

Cork flooring does offer the advantage of “feeling” warm underfoot because it does not conduct heat very well, and so can contribute to a space that doesn’t require as high a thermostat setting because occupants feel warmer.

Material costs: moderate to high

Type of backing and finish will have a large impact on cost.

Labour Input: moderate to High

Similar to other pre-finished floorings.

Skill level required for homeowners

Preparation of sub-floor — Easy

Installation of floor — Easy to Moderate

Click-down flooring requires minimal tools and experience. Flooring that is fastened with nails or staples requires slightly more skill.

Finishing of floor — Easy

Pre-finished.

Sourcing & availability: Easy

Cork flooring has seen a significant growth in popularity, to some degree because of its environmental benefits. It can be obtained from most building supply outlets and specialty flooring shops.

Durability: moderate

The soft, pliable nature of cork means this type of flooring is prone to wear issues. Properly maintained and used in areas that are not high-traffic and/or subjected to regular wetting, cork flooring can last from ten to fifty years.

There are several issues that affect the lifespan of cork. Abrasion can wear down cork flooring, making it inappropriate for muddy, sandy or otherwise dirty locations where dirt can abrade the surface. Cork is also negatively affected by UV light, causing color changes and degradation of the surface over time. While there are naturally occurring water repellents in cork, the flooring is not durable under consistently wet conditions that can affect the surface finish and the wood-fiber backing material.

Most manufacturers recommend refinishing cork floors occasionally, depending on wear patterns.

Code compliance

Most codes are not prescriptive when it comes to finished flooring materials, as long as the sub-floor has been constructed to code and in a manner intended to support the dead load imposed by the flooring.

Indoor air quality: moderate to high

Cork itself is relatively benign for IAQ, but a number of the products associated with the cork flooring system may have negative impacts that range from negligible to high. Wood-fiber backing boards are typically made with formaldehyde glues, and surface finishing products are typically petrochemical based and may off-gas over the short and/or long term. In addition, most manufacturers recommend fairly frequent refinishing of the surface, and the majority of products are petrochemical based.

There are third-party certified versions of cork flooring, which should be sought if IAQ is of concern.

Resources for further research

Jeffries, Dennis. The Flooring Handbook: The Complete Guide to Choosing and Installing Floors. Toronto, ON: Firefly, 2004. Print.

Future development

The world’s cork supply is limited, as the cork oak only grows in particular climatic and soil conditions in a small region of the world. Trees take twenty-five years to reach maturity for harvesting, and may only be harvested on seven- to twelve-year cycles. This means that there can never be enough cork to supply more than a small portion of the world’s flooring needs, and as pressure increases on the limited supply the price will remain high or climb higher. While it may be feasible to make a very sustainable building using well-sourced cork flooring, it is not a solution that will serve more than a small number of homeowners.

Tips for a successful cork floor

1. Sheet cork and laminated cork have different thicknesses and application processes, and a decision to use one or the other should be made at the planning stage in order to ensure proper detailing.

2. Cork flooring is only available as proprietary systems, with manufacturers supplying installation instructions that should be followed carefully.