Clay Plaster

Finishes: MATERIALS ENCYCLOPEDIA

Applications for this system

Finish coat for application over most interior substrates, including plaster, drywall, magnesium oxide board, brick, stone, concrete and sheet wood materials

Basic materials

Clay

Fine sand

Fiber (straw, hemp or other natural fiber)

Pigments, if desired

Admixtures (can include flour paste, natural oil, hydrated lime, among others)

Adhesion coat, if required

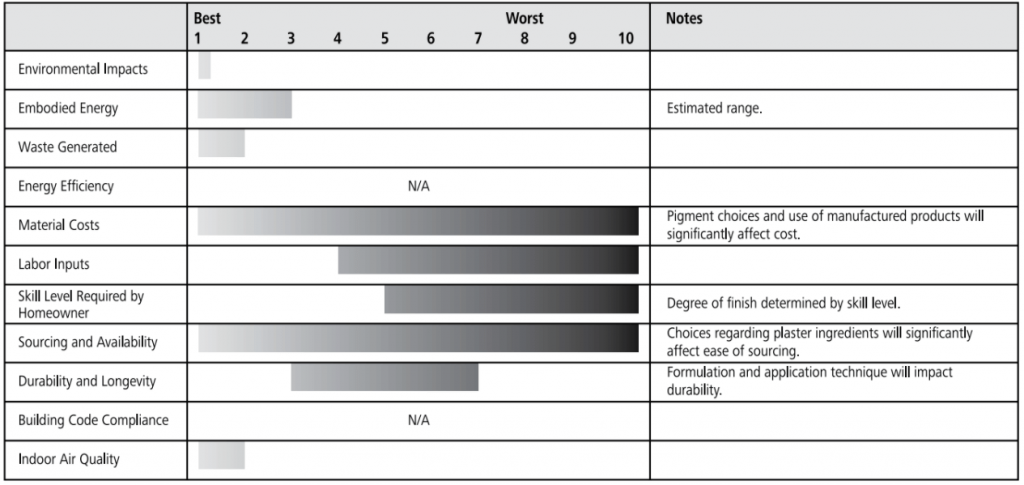

Ratings Chart for Clay plaster

The ratings chart shows comparative performance in each criteria category. Click on the tabs below for detailed analysis of each criteria.

- HOW THE SYSTEM WORKS

- ENVIRONMENTAL IMPACTS

- WASTE

- MATERIAL COSTS

- LABOUR INPUT

- SKILL LEVEL REQUIRED

- SOURCING & AVAILABILITY

- DURABILITY

- INDOOR AIR QUALITY

- RESOURCES

- FUTURE DEVELOPMENT

Clay plaster System

Clay finish plasters are very similar to the clay sheathing plaster described in the previous chapter, but applied as a very thin skim coat. The thinness of the coating requires finer grades of aggregate, but the general mix ratios remain similar, with one part of clay to two to three parts of fine aggregate. Admixtures are common to add strength and abrasion resistance to the plaster.

For application over smooth, unplastered substrates, an adhesion coat is typically used to help the plaster to bond to flat surfaces. This coat is a mixture of sand and glue (natural flour paste or casein glue) that is brushed or rolled onto the wall, creating a textured surface.

Many different finishing techniques are used on clay finish plasters, from a highly polished surface to a rough trowel or skip trowel look. The choices in surface texture are almost limitless.

Most natural pigments take very well to clay plaster, giving rich colors and a sense of depth that is quite unlike painted surfaces.

Environmental Impact Rating

Harvesting — Negligible to Moderate

Clay plasters made from soils found on or near the construction site will have minimal impacts. Bagged clay is extracted from clay pits, and impacts from the pits can include habitat destruction and silting of ground- and surface-water.

Crushed sand is typically found in every region, and extraction from aggregate pits can have impacts including habitat destruction and silting of ground- and surface-water.

Manufacturing — Negligible to Low

Site soils require no manufacturing process and only low impact if mixed on-site. Manufactured clays are dried and ground to fine powder, which is a low-impact process. Some bagged clays are heated to dry them, adding appreciable embodied energy.

Sand is a product of the aggregate industry, made from extracting sand and stone from quarries and, when necessary, crushing, washing and screening the sand to the desired size. This is a low-impact process.

Transportation – Negligible to High

Site soils will need no transportation. Bagged clay is likely to require shipping, as clay is not processed in every region. As a heavy material, clay will have significant transportation impacts if it travels long distances.

Sand can be found locally in most regions.

Installation — Negligible

Waste: Negligible

Biodegradable/Compostable — All plaster ingredients may be left in the environment. Plaster is mixed in fairly small batches, so quantities should be minimal.

Recyclable — Packaging of bagged clay. Quantities can be low to high, depending on the amount of bagged clay required.

Landfill — None.

Material costs: Low to high

Ingredients for clay plaster are relatively low cost, but some natural pigment colors can add significantly to the cost. Manufactured products are significantly more expensive than homemade versions.

Labour Input: moderate to High

Clay plasters can be labor intensive. The wall surface may need an adhesion coat, which must be mixed and applied. Clay plaster ingredients must be mixed with water in advance of application. Clay finish plaster is applied in one or two coats, as required by the desired appearance. Single-coat finishes are typically less expensive.

Health Warning

Powdered clay and dry sand can both create a lot of dust that is high in silica content, and is dangerous to breathe. Chopped fiber can also be very dusty. Wear proper breathing protection whenever handling dusty materials.

Skill level required for homeowners

Preparation of wall surface — Moderate

Masking of edges must be done carefully, as the tapelines will translate directly to the quality of the finished appearance. The adhesion coat must be site-mixed and is brushed and/or rolled onto the wall. This step will not be required if the plaster is being applied to an existing clay plaster base or a textured, porous surface.

Application of finish — Moderate to Difficult

Experience with skim coat plaster is recommended, as the troweling skills and techniques for a fine finish take some practice to acquire.

Clay skim plaster can be the final finish, or a variety of paints and sealants may be applied over a clay finish plaster for added visual effect, or to provide a color change in the future.

Sourcing & availability: Easy to Difficult

All the ingredients for clay plasters are widely available. Site soils may require no off-site sourcing. Individual ingredients must be obtained from different sources. Bagged clay typically comes from pottery supply outlets, sand from a local quarry and chopped straw or other fiber from local farms or farm supply outlets. Pigments and admixtures also require separate sourcing.

There are several sources for manufactured clay finishing products, which can be bought from manufacturers or from specialty sustainable building shops.

Durability: moderate

Clay plasters are very durable in any dry interior location, and should not require regular maintenance. Like other mineral-based sheathing, they are prone to denting and chipping when hit with sufficient force. Constant abrasion can be problematic if the mix does not contain adequate binder.

Indoor air quality: high

Clay plasters can have a positive effect on IAQ. Limited testing shows that they are capable of taking impurities out of the air and storing or transforming them. Clay can be a source of beneficial negative ions in the home.

If a clay plaster is not properly formulated, it can be dusty and contribute problematic fine silica particulate to the air.

Resources for further research

Guelberth, Cedar Rose. and Daniel D. Chiras. The Natural Plaster Book: Earth, Lime and Gypsum Plasters for Natural Homes. Gabriola Island, BC: New Society, 2003. Print.

Crews, Carole. Clay Culture: Plasters, Paints and Preservation. Taos, NM: Gourmet Adobe, 2009. Print.

Weismann, Adam, and Katy Bryce. Using Natural Finishes: Lime- and Earth-Based Plasters, Renders and Paints: A Step-by-Step Guide. Totnes, UK: Green, 2008. Print.

Future development

Clay plasters offer a remarkably low-impact, high-durability and uniquely beautiful option for interior finishing. Bagged, pre-mixed versions are being developed and are just beginning to gain a foothold in the market. The beauty, simplicity and user-friendliness of clay plasters make them an ideal development in sustainable building.

Tips for a successful clay plaster finish

1. Ingredients for clay plasters can come from naturally occurring local soils or from manufactured bagged clay or aggregate. If you hope to work with site soil, first ascertain its condition (moisture content, rock/stone content) and the ratio of clay, silt and sand to determine whether it is appropriate. Finish coats require very fine particle sizes, and site soil mixes may require more preparation than those used for bulk coats due to the screening of larger particles.

2. Work from an established recipe for clay plaster, or prepare test samples to refine a custom mix to best meet the needs of the project. Create samples with the same surface finish intended for use.

3. A good plastering job requires properly placed plaster stops or transition considerations at every junction. Careful masking/preparation of all edges will produce a professional appearance. Pull tape before plaster hardens to avoid uneven edges.

4. Clay plasters can develop a “cold edge” while being applied. These seams will be apparent in the finished appearance, so be sure to start and finish sections of wall that can be completed in one continuous application.