Natural Oil Paint

Finishes: MATERIALS ENCYcLOPEDIA

Applications for this system

Wood

Porous surfaces (including plaster)

Not suitable for use on:

– Metal

– Previously painted surfaces

– Surfaces requiring high vapor permeability

Basic materials

Natural, siccative (oxidizing) oil (typically cold-pressed linseed, but can be semi-siccative oil like walnut, hemp, poppy, tung, sunflower, safflower, soya and even fish oil)

Solvent thinner (typically citrus thinner or natural alcohol)

Pigment

Admixtures, as required (may include pine resin, drying agents and polymerizing compounds)

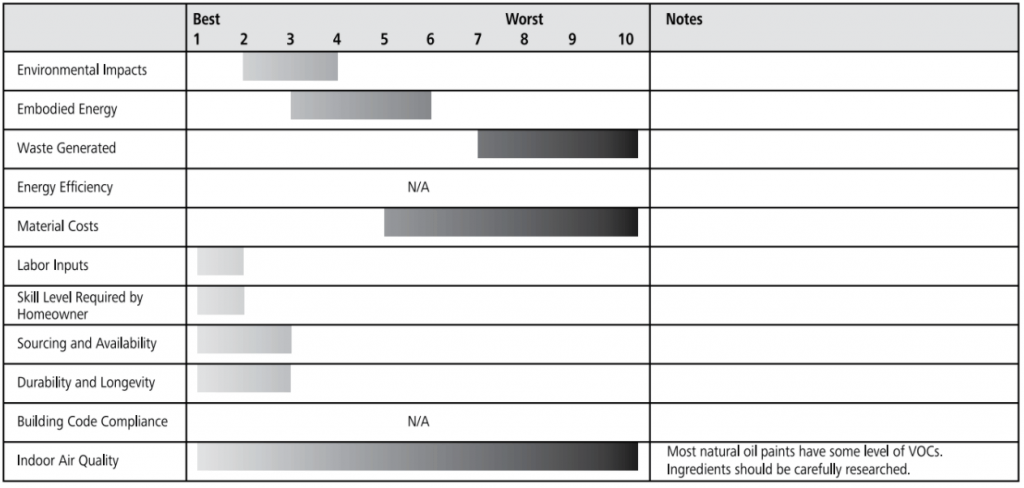

Ratings Chart for Natural oil paint

The ratings chart shows comparative performance in each criteria category. Click on the tabs below for detailed analysis of each criteria.

- HOW THE SYSTEM WORKS

- ENVIRONMENTAL IMPACTS

- WASTE

- MATERIAL COSTS

- LABOUR INPUT

- SKILL LEVEL REQUIRED

- SOURCING & AVAILABILITY

- DURABILITY

- INDOOR AIR QUALITY

- RESOURCES

- FUTURE DEVELOPMENT

natural oil paint System

The household paints that are commonly referred to as “oil paints” are actually alkyd paints. Drying alkyd resins are a type of polyester that is modified with fatty acids. The polyester base is derived from polyols (typically based on glycerin, sucrose, ethylene glycol or pentaerythritol) and dicarboxylic acid or carboxylic acid anhydride.

Natural oil paints are those in which the resin is natural oil. While many oils are suitable for creating paint, linseed oil (pressed from flax seed) is by far the most common. Natural oils are extremely slow to dry (some never dry completely) and require a solvent to dry sufficiently for use as paint. Natural turpentine and citrus solvent are the two most common drying agents for natural oil paint. Solvent content in oil paint can be very high, and even natural solvents contain volatile organic compounds (VOCs) that can have ill effects on health. Synthetic solvents tend to have worse health impacts, but proper ventilation is a necessity and those with chemical sensitivities should be sure that natural solvents are not a trigger.

During the drying process for oil paints (though dry to the touch in a matter of days, full drying can take months), the oil undergoes a natural polymerization. In recent years, advances in polymerizing natural oils have resulted in oil paints that dry faster and harder without requiring as much solvent. Some of these processes are natural, while others are chemical.

Pigments must be oil-soluble in order to work in this type of paint, which can limit the available color palette.

Environmental Impact Rating

Harvesting — Low to Moderate

Natural oils are pressed from seeds. Seed crops are grown in a wide variety of manners all over the world, from small-scale organic to factory farms. Some oil-bearing seed crops (flax and hemp, in particular) also bear useful fibers in their stems, resulting in a harvest with very little waste. Impacts will vary greatly, and can include habitat destruction, pesticide and herbicide runoff and soil depletion.

The two most common types of natural solvents are turpentine and citrus solvent. Turpentine is distilled from pine resin, with relatively low impacts from harvesting. Products called citrus thinners can have a range of ingredients, from pure citrus oil (extracted from lemon, orange and/or grapefruit rind) to blends of citrus oil and mineral oil and herbal essential oils. Citrus growing can have significant impacts, including high pesticide, fungicide and herbicide use. However, the fruit rind is a secondary product of citrus farming, and its use helps to reduce waste.

Manufacturing — Low

Cold-pressing of seed oils is a low-energy and low-impact mechanical process.

The distillation of turpentine and extraction of citrus oil are both low-energy, low-impact processes. Most manufacturers now recapture emitted VOCs, which are the most detrimental impact.

Transportation — Low to High

Check manufacturer proximity to job site and distribution network to ascertain impacts.

Installation — Low to Moderate

Cleanup from oil painting requires the use of additional solvent to remove paint from brushes and rollers. Significant volumes of used solvent can be highly impactful if sent down drains or spread on the soil.

Waste: high

Biodegradable/Compostable — Natural oil paints are made with all-natural ingredients, but they are not well suited to biodegradation at a household level. The oils will remain sticky and persistent for a very long time, creating problems in compost piles or in the soil.

Recyclable — Paint containers.

Hazardous Waste — Oil paint that cannot otherwise be used should be sent to a hazardous waste facility.

Material costs: moderate to high

A variety of price points are available from a range of manufacturers.

Labour Input: low

Natural oil paints are similar in application time to conventional paints, with two coats normally required.

Health Warning

Natural solvents are not nontoxic. Turpentine, in particular, can be dangerous to work with. Citrus solvent is much preferable to turpentine, but read the product label for handling instructions.

Skill level required for homeowners

Preparation of substrate — Easy

No preparation required.

Application of finish — Easy to Moderate

Conventional brush and/or roller application is used. Thick paint may take additional care to achieve a high degree of finish.

Sourcing & availability: moderate

All the ingredients for natural oil paint are available from artist supply outlets. Bulk quantities of natural, cold-pressed oils may require specialty sourcing.

Commercial oil paints are produced and can be obtained from specialty sustainable building suppliers.

Durability: High

Natural oil paints create a very flexible coating, able to expand and contract with the substrate material. This makes them ideal for coating plaster and drywall, and they provide a durable finish for interior and exterior wood. They are water repellent and can be washed. They are easier to scratch than chemical-based paints, and will not retain a high degree of gloss if touched or rubbed. This does not affect lifespan, only appearance.

Indoor air quality: low to high

Some natural oil paints may have a negative impact on IAQ. Paints using turpentine or chemical solvent should be avoided, as these will emit high quantities of VOCs over a long period of time. Paints using citrus solvents will also emit VOCs, though there is evidence that these emissions are not as dangerous to human health. The chemically sensitive should research reactivity to citrus oil before using these paints.

Natural oils themselves also emit VOCs. Each oil type is different in this regard, and reactivity to various types of oil should be researched. Some people find the fragrance of natural oil paints to be pleasing, while others find it distracting or distressing. All paint manufacturers will disclose their VOC content, with some paints qualifying as no-VOC.

Resources for further research

Weismann, Adam, and Katy Bryce. Using Natural Finishes: Lime- and Earth-Based Plasters, Renders and Paints: A Step-by-Step Guide. Totnes, UK: Green, 2008. Print.

Edwards, Lynn, and Julia Lawless. The Natural Paint Book: A Complete Guide to Natural Paints, Recipes, and Finishes. Emmaus, PA: Rodale, 2002. Print.

Safecoat AFM Naturals, see afmsafecoat.com/products.php?page=4

Allbäck linseed oil paints, see linoljeprodukter.se/eng/

Future development

Natural oil paints have been used for thousands of years, only losing their place in the market in the past half century, and they have been seeing a slow but growing resurgence in recent years. Advances in the availability of citrus-based solvents and oil production and polymerization have created a new breed of oil paints that avoid many of the drawbacks of traditional versions. Advances in natural chemistry may further improve on the qualities of these paints, and consumer demand for environmentally friendly coatings may increase the market share for natural oil paint.

Tips for a successful natural oil paint finish

1. Ensure that drying time for natural oil paint does not interfere with construction schedule. Some paints may require 2–7 days to dry, and while wet will trap airborne dust and be vulnerable to water and direct contact. Commercially produced natural oil paints tend to have shorter drying times.

2. Natural oil paints are often stickier than other coatings, and may require attention to detail to eliminate brush marks and overlap marks.

3. Manufactured natural oil paints are proprietary products. Follow the manufacturer’s instructions for successful application.