Milk Paint

Finishes: MATERIALS ENCYcLOPEDIA

Applications for this system

Wood (interior and exterior)

Plaster (interior)

Drywall (interior)

Not Suitable for:

– Floors, unless treated with oil or sealant

– Previously painted surfaces (require additional binder)

– Metal (requires additional binder)

– Plastic

Basic materials

Casein (milk protein)

Lime or borax

Clay and/or calcium carbonate

Pigment

Microfibers (if required)

Admixtures (if required)

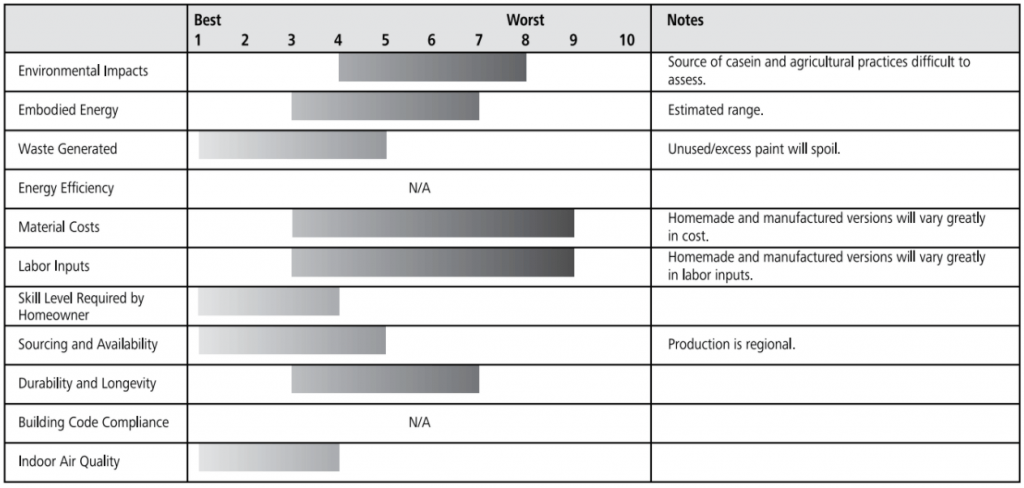

Ratings Chart for Milk Paint

The ratings chart shows comparative performance in each criteria category. Click on the tabs below for detailed analysis of each criteria.

- HOW THE SYSTEM WORKS

- ENVIRONMENTAL IMPACTS

- WASTE

- MATERIAL COSTS

- LABOUR INPUT

- SKILL LEVEL REQUIRED

- SOURCING & AVAILABILITY

- DURABILITY

- INDOOR AIR QUALITY

- RESOURCES

- FUTURE DEVELOPMENT

milk paint System

The homeowner can purchase milk paint as ready-made dry powder from a number of manufacturers, or mix it from the basic ingredients.

The effectiveness of milk paint is based on the properties of casein molecules, which contain a glue-like substance. In the presence of a base chemical like lime or borax, the casein molecule is opened and the glue (calcium caseinate) made soluble in the mixture. Powdered fillers like clay and/or calcium carbonate give the paint “body” and pigments add the color. Microfibers (such as cellulose) can add further body, and a number of natural or chemical admixtures may be added to give particular properties to the paint.

Once mixed with water, the paint requires a short amount of time (20–60 minutes) for the reaction between the casein and lime to occur. It is then applied by brush or roller, typically in two or three coats for fully opaque coverage. Additional water can be added to the mix to create a stain or wash effect. The largest use for milk paint is on furniture, where it is used to accurately replicate historic milk paint finishes and colors and where the many potential wash and antiquing effects it can create are most desired.

Milk paints are reasonable permeable, but there are no published test results or standards at this time to give an accurate indication of how permeable and in what conditions.

In areas where high wear or water exposure is expected, an oil or wax finish can be applied over the milk paint to add a further degree of protection. These coatings will reduce permeability while increasing water repellency.

Environmental Impact Rating

Harvesting — Moderate

Cow’s milk is the raw ingredient for casein production. Harvesting techniques vary greatly, but dairy farming can have impacts that include habitat destruction, methane release from cows and potential water contamination from manure.

Lime is quarried from pits, with attendant habitat destruction and potential surface and groundwater contamination.

Clay and pigments are harvested from surface pits with relatively low impacts.

Manufacturing — Moderate to High

Casein is extracted from raw milk through a multi-stage process that includes pasteurization (requiring heat), filtering, incubation, decanting, drying (requiring heat) and crushing. There are several useful by-products created during this process, mitigating the energy inputs.

Lime is crushed and heated to very high temperatures with significant carbon emissions and air pollution.

Transportation — Moderate to High

The ingredients for milk paint will have been assembled from different points of manufacture. Casein production for commercial use is based in Eastern Europe.

Installation — Negligible

Waste: Low to moderate

Compostable — Leftover milk paint can be added to a compost pile or sent down the drain.

Recyclable — Paint containers

Material costs: moderate to high

Raw ingredients for home made milk paint are moderately priced, with some pigments adding significant costs. Manufactured versions are more costly.

Labour Input: moderate

Milk paint must be mixed with water prior to applying, and allowed to sit for at least twenty minutes before use. This adds a small amount of additional labor time. Otherwise, the application process is the same as any type of paint.

If a natural oil will be used to protect the milk paint, this will add another step, taking the same length of time as another coat to apply.

Health Warnings

Powdered milk paint contains silica dust, and breathing protection should be worn while handling dry powder. The lime content of the paint makes it mildly caustic to skin; wearing gloves and eye protection is recommended.

Skill level required for homeowners

Preparation of substrate — Easy

Porous substrates require no preparation. Painted surfaces may require a coat of acrylic binder or an amount of acrylic binder added to the milk paint.

Application of finish — Easy to Moderate

Brush and/or roller application. Careful brushing may be required to avoid bubbles on the surface.

Sourcing & availability: Easy to moderate

The raw ingredients to mix milk paint are widely available. While casein powder may be difficult to locate in small quantities, skim milk powder can be used in its place to make milk paint. Lime, calcium carbonate and some types of pigment are available at masonry supply stores. Artist supply stores will have more types of pigment and are more likely to carry natural pigment if desired.

Several companies in North America manufacture high-quality milk paint with consistent coloration and formulation. Some have distribution through paint and green building supply stores; all will ship directly to homeowners.

Durability: low to moderate

Milk paint was very widely used in the pre-petrochemical age. It takes around thirty days to fully cure, and in this time is vulnerable to water. Once dry to the touch, milk paint will not be removed easily with water, but may show spotting within the first month if splashed.

Milk paint has the qualities of both stain and paint. On porous surfaces, it will soak into the substrate and bond with the material to provide protection and pigmentation. The more coats that are added, the more the paint acts like a coating, offering additional protection but also becoming vulnerable to cracking and peeling over time.

Used indoors in relatively dry areas, milk paint has a lifetime from fifteen to fifty years. It is possible to add additional coats of milk paint over time.

Used outdoors, milk paint will help to protect wood and will remain quite colorfast for about ten years. Over time, it will fade and wear. Many old barns were treated with milk paint, and it’s possible to see the faded colors on those that haven’t been treated with modern paints.

It is possible to extend the lifespan and water-resistance of milk paints by treating them with natural oil (see section below).

Indoor air quality: high

Milk paint will have no adverse effect on IAQ.

Resources for further research

Weismann, Adam, and Katy Bryce. Using Natural Finishes: Lime- and Earth-Based Plasters, Renders and Paints: A Step-by-Step Guide. Totnes, UK: Green, 2008. Print.

Edwards, Lynn, and Julia Lawless. The Natural Paint Book: A Complete Guide to Natural Paints, Recipes, and Finishes. Emmaus, PA: Rodale, 2002. Print.

Future development

Milk paint formulas have been used for centuries. Modern processing of casein and lime can result in much more consistent products. It is possible that advances in natural chemistry may result in improvements in milk paint.

Consumer demand for nontoxic finishes seems to be increasing, and milk paint could certainly fill some of that demand. Users need to be willing to commit to the additional step of mixing the dry ingredients with water to get the beneficial trade-off of a beautiful, nontoxic finish.

Tips for a successful milk paint finish

1. Measure dry ingredients and water ingredients carefully and mix thoroughly. Small variations in water quantity can affect appearance noticeably, especially with darker colors.

2. Mechanical mixing (hand blender or food processor) helps to ensure even distribution of dry ingredients and pigment. Let mixed paint sit for at least twenty minutes prior to use, to allow the calcium caseinate to form.

3. Milk paint can often develop a foamy layer when mixed, and careful brushing may be required to eliminate bubbles from the finished surface.

4. There can be noticeable differences in color between batches of milk paint. Use a “continuous mixing” process in which one batch is used until it is half finished, and then half of the next batch is added to the remaining half of the previous batch. This will help to ensure that there are no dramatic shifts in color in one area.

5. Once mixed with water, milk paint can spoil, especially in hot weather. Unused paint will last 7–10 days if kept refrigerated.