stone

cladding: MATERIALS ENCYcLOPEDIA

Applications for this system

Exterior cladding (rainscreen)

Interior cladding

Solid interior or exterior walls

Basic materials

Natural stone

Mortar (lime, sand, cement, if required

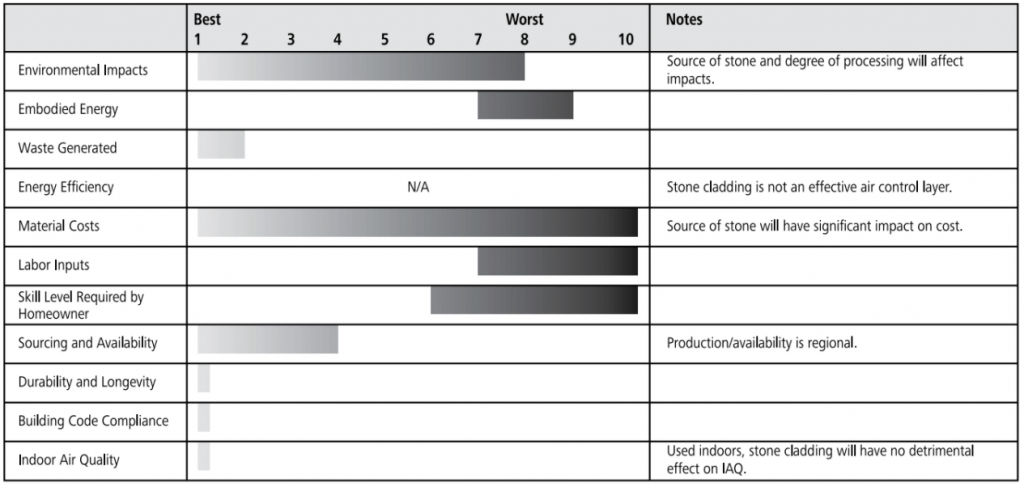

Ratings Chart for Stone Cladding

The ratings chart shows comparative performance in each criteria category. Click on the tabs below for detailed analysis of each criteria.

- HOW THE SYSTEM WORKS

- ENVIRONMENTAL IMPACTS

- WASTE

- EMBODIED CARBON

- ENERGY EFFICIENCY

- MATERIAL COSTS

- LABOUR INPUT

- SKILL LEVEL REQUIRED

- SOURCING & AVAILABILITY

- DURABILITY

- CODE COMPLIANCE

- INDOOR AIR QUALITY

- RESOURCES

- FUTURE DEVELOPMENT

Stone Cladding System

Stone of a suitable composition is harvested and either used in an unmodified form or cut/shaped to a desired dimension and profile. The stone is laid in successive courses, bonded by a mortar of lime/sand or lime/cement/sand. There are many different patterns for stonework, but most feature offset joints between courses. Keystone arches can be formed to create self-supporting openings, or metal reinforcement is used to form straight openings.

When used as cladding, stone is attached to the structural sheathing by means of metal ties that are nailed to the wall and embedded in the mortar joint, and a space is left between the stone and the sheathing to create a rainscreen. Weeper holes are left at intervals in the top and bottom courses to allow moisture to escape.

When used structurally, stone walls are typically one part of a double wall, with an insulated core between the two wythes. Ties are placed at intervals between the two walls to increase stability. It is rare for stone to be used structurally in modern construction in North America.

Not Manufactured Stone

A great deal of stone cladding used in modern building is not natural stone, but a cement product manufactured to look like stone. Manufactured stone can have a wide range of appearances and qualities, and is typically less expensive than natural stone. It has the high impacts associated with cement products. A case can be made for the use of manufactured stone as a green building product, largely based on its durability. It is not included in this book because of its high carbon footprint and because it is an intensive material to be used non-structurally as a cladding.

Environmental Impact Rating

Harvesting — Negligible to Moderate

Stone is a non-renewable but abundant resource. Some naturally occurring stone can be harvested directly from the surface of the ground on the building site. Most commercially available stone is quarried from established pits, where it is mechanically extracted. Impacts may include habitat destruction and ground and surface water contamination. Stone may be usable directly from the quarry, or may require further cutting and shaping.

Lime and/or cement for mortars are made from quarried limestone. Impacts can include habitat destruction and surface and ground water contamination.

Sand for mortars is quarried with low impacts.

Manufacturing — Negligible to Moderate

Stone may require little to no manufacturing after harvesting, as some stone will be suitable for building walls in its naturally occurring state. Other stone will be quarried in large pieces and then sawn or split into shapes that are suitable for cladding. These processes are not very energy intensive and typically have minimal impacts that can include release of silica dust and water contamination.

Mortar ingredients require heating of limestone to high temperature, with resultant high fossil fuel use and emissions and impacts including air and water pollution.

Transportation — Negligible to High

Sample building uses

As a heavy material, the transportation impacts of stone will increase with distance from harvesting and manufacturing source.

Installation — Negligible

Waste: Low

Compostable — Stone may be left in the environment or used as aggregate or fill.

Recyclable — None.

Landfill — Bags for mortar ingredients.

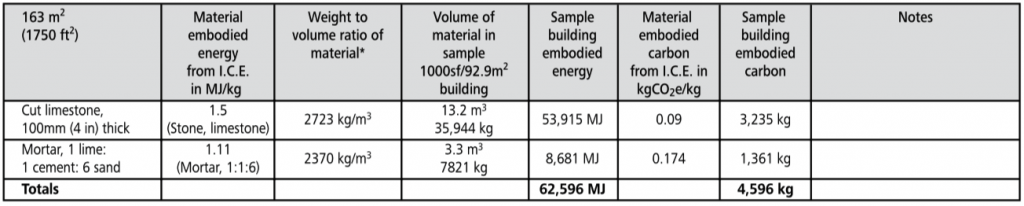

Chart of Embodied energy & carbon

Energy Efficiency

Stone is most commonly a rainscreen cladding and does not act as the primary air control layer. The thermal mass properties of stone walls may help to moderate temperature swings, especially in indoor applications, but stone walls have no appreciable thermal control benefits.

If stone is being used as a structural wall, it may be difficult to make the wall air tight due to the number of joints and the variegated surface of the stone. Another form of primary air barrier (plaster coating, sheet material) may be necessary to make the wall airtight and efficient.

Material costs: Low to high

The source of stone and the degree of manufacture to shape the stone will greatly influence the price.

Labour Input: High

Site-harvested stone can be very labor intensive, including the digging, lifting and sorting of a heavy material. The wall requires preparation including the fastening of ties. Laying the walls requires the mixing of mortar, laying of stone and finishing of joints.

Health Warning

Stone cutting and mortar mixing can cause exposure to high quantities of silica dust, so proper breathing protection is required.

Skill level required for homeowners

Preparation of substrate — Easy

Wall framing and sheathing skills are required. The process of measuring and fastening stone ties is straightforward.

Installation of sheathing — Difficult

There is a lot to learn in order to successfully install stone cladding. Skills required include marking and measuring for courses, mortar mixing, laying mortar and stone and creating appropriate headers/arches for openings. The varied nature of stone requires aesthetic decisions while laying stone. Without prior experience or practice, stone masonry may best be left to professionals.

Finishing of sheathing — Easy

Jointing between the stones is the only finish required once stone is installed.

Sourcing & availability: Easy to moderate

Natural stone is available directly from quarries and through masonry supply stores. Mortar materials are available from building supply centers and masonry supply stores.

Durability: Very High

Stone cladding and walls will last for hundreds of years, with the mortar joints being the weakest element. Proper attention to maintenance of mortar joints (every ten to twenty years) will greatly extend the lifespan of a stone wall.

Code compliance

Stone is an acceptable solution in some codes. Though stone construction has a lot of historical precedent, the use of natural stone in modern construction is rare enough that some codes no longer directly reference it as an acceptable solution. There are sufficient published standards to make a reasonable case for its acceptance as an alternative solution in these jurisdictions.

Indoor air quality: high

Used indoors, natural stone is unlikely to have a negative effect on IAQ. The exception would be stone that emits radon gas, a naturally occurring radioactive gas associated with some types of granite and limestone in some regions. Radon gas is a serious contaminant with carcinogenic properties.

Resources for further research

Gallagher, A. Robert., Joe Piazza, and Sean Malone. Building Dry-Stack Stone Walls. Atglen, PA: Schiffer, 2008. Print.

McRaven, Charles. Building with Stone. Pownal, VT: Storey Communications, 1989. Print.

Long, Charles K. The Stonebuilder’s Primer: A Step-by-Step Guide for Owner-Builders. Willowdale, Ont.: Firefly, 1998. Print.

Cramb, Ian. The Art of the Stonemason. White Hall, VA: Betterway Publications, 1992. Print.

McRaven, Charles. Stonework: Techniques and Projects. Pownal, VT: Storey, 1997. Print.

McRaven, Charles. Building Stone Walls. Pownal, VT: Storey, 1999. Print.

Flynn, Brenda. The Complete Guide to Building with Rocks and Stone: Stonework Projects and Techniques Explained Simply. Ocala, FL: Atlantic Group, 2011. Print.

Future development

Stone wall construction is unlikely to experience major changes or innovations, as the system has been refined over centuries and the raw materials are largely unrefined. In regions where appropriate stone is available, the costs of natural stone may become more favorable compared to manufactured alternatives as the price of fuel rises. However, the high amount of labor and skill required are likely to keep stone wall construction to a small portion of the overall market.

Tips for successful stone cladding

1. Before using a natural stone, especially site-harvested stone, ensure it has suitable properties for use as a cladding. Some natural stone is prone to cracking due to moisture absorption and freeze/thaw cycles.

2. Stone cladding must be designed into the project from the start, as it will require a ledge on the foundation and proper detailing for doors, windows and flashing to suit the thickness of the wall.

3. There are many excellent resources available to assist in the successful installation of stone cladding. Be sure to seek proper advice and instruction.

4. Stone can make an attractive interior wall or wainscoting. For some interior applications, it may be load-bearing and/or self-supporting.