rammed earth

Walls: MATERIALS ENCYcLOPEDIA

Applications for this system

Load-bearing wall systems

Interior walls

Built-in furniture, benches

Decorative Elements

Basic materials

Earth

Stabilizer (cement or lime where required)

Insulation (where required)

Water-resistant finish (where required)

Control layers:

Water — The finished rammed earth is typically the water control layer. It is possible to use vapor-permeable, water-resistant finishes on the rammed earth surface or to include water-resistant additives in the earth mix before ramming. Additional cladding over the rammed earth is feasible but rarely done.

Air and vapor — Solid, continuous and dense, rammed earth is an effective air and vapor control layer.

Thermal — A rammed earth wall requires an additional thermal control layer in hot or cold climates (see Thermal Mass vs. Insulation sidebar). This layer can be on the interior, exterior or center of the wall, and is typically a rigid insulation.

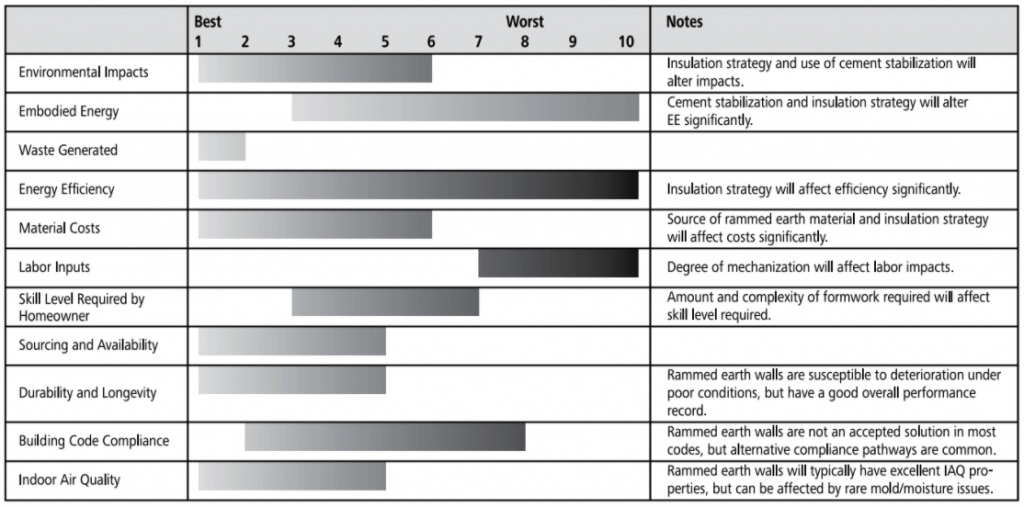

Ratings Chart for Rammed Earth walls

The ratings chart shows comparative performance in each criteria category. Click on the tabs below for detailed analysis of each criteria.

- HOW THE SYSTEM WORKS

- ENVIRONMENTAL IMPACTS

- WASTE

- EMBODIED CARBON

- ENERGY EFFICIENCY

- MATERIAL COSTS

- LABOUR INPUT

- SKILL LEVEL REQUIRED

- SOURCING & AVAILABILITY

- DURABILITY

- CODE COMPLIANCE

- INDOOR AIR QUALITY

- RESOURCES

- FUTURE DEVELOPMENT

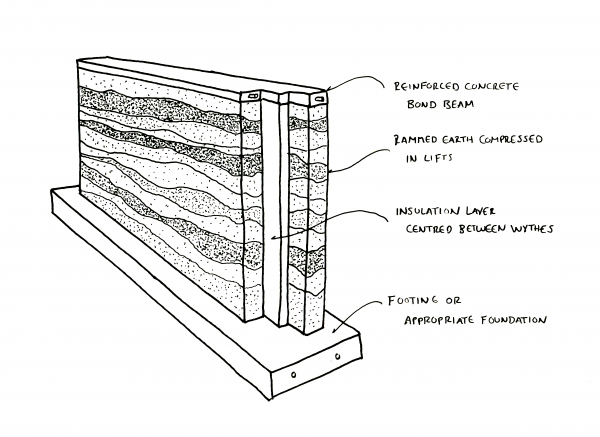

Rammed Earth System

A lightly moistened earth mix with a relatively low clay content (10%–30% is common) is placed into forms in lifts, then tamped heavily to achieve a desired level of compaction. The soil mix varies by region and builder, but it is common to “stabilize” the mix with a small amount (3%–9%) of portland cement or other hydraulic binder.

A lightly moistened earth mix with a relatively low clay content (10%–30% is common) is placed into forms in lifts, then tamped heavily to achieve a desired level of compaction. The soil mix varies by region and builder, but it is common to “stabilize” the mix with a small amount (3%–9%) of portland cement or other hydraulic binder.

The walls are built up in continuous lifts to full height. Often they are built in sections, so that formwork is not needed continuously around the building.

Window and door openings are usually created using a wooden “volume displacement box” or VDB. These VDBs hold the place of the window or door as tamping occurs around them. Once the wall is complete the VDB is removed, leaving a well-formed opening in the wall.

For large openings, lintels of wood, concrete or steel can be used above the opening; these are often buried in the rammed earth so they cannot be seen in the finished wall.

Electrical wiring and switch boxes (or conduits to receive them) are placed in the formwork before adding earth and tamping, and are formed right into the wall. Surface mounting after construction is also possible.

At the top of a rammed earth wall is a bond beam made of poured concrete, wood or steel. The beam is fastened to the top of the wall to provide a continuous attachment point for a roof. The method of fastening will depend on expected wind and seismic loads.

In hot or cold climates, insulation is part of a rammed earth wall system. The insulation can be a continuous wrap on the interior or exterior of the wall, but more commonly it is centered in the wall. Types of insulation used will vary with climate, availability, compressive strength and environmental factors.

Rammed earth walls are usually left exposed to provide the finished surface. A variety of sealants can be used on the raw earth to leave it visible but add protection from water. Plasters and others sidings are rarely used but are possible finishes.

Environmental Impact Rating

Harvesting — Negligible to Moderate

Site soil can be harvested with negligible impacts. Amending materials like sand and cement have low to moderate impacts including habitat destruction and water contamination from quarrying.

Steel for reinforcing bar is extracted in a high-impact manner, with effects including habitat destruction and ground water contamination.

Manufacturing — Negligible to Moderate

Soil can be extracted and processed with negligible to low impacts.

Portland cement, if used, is fired at extremely high temperatures and has high impacts including fossil fuel use, air and water pollution and greenhouse gas emissions.

Steel reinforcement bar is made in a high-heat process that uses a lot of fossil fuel, and has impacts that include air and water pollution.

Transportation — Negligible to Moderate

Sample building uses 79,410 – 105,666 kg of rammed earth:

74.6 – 99.3 MJ per km by 35 ton truck

Soil, cement and steel are heavy materials, and accrue significant impacts proportional to distance traveled.

Installation — Negligible to Moderate

The process of ramming the soil mixture can be done manually with negligible impact. More often, hydraulic machinery is used, with moderate impacts depending on power source.

Waste: Low

Biodegradable/Compostable — All leftover earth materials.

Recyclable — Metal reinforcement bar.

Landfill — Manufactured insulation offcuts, cement bags.

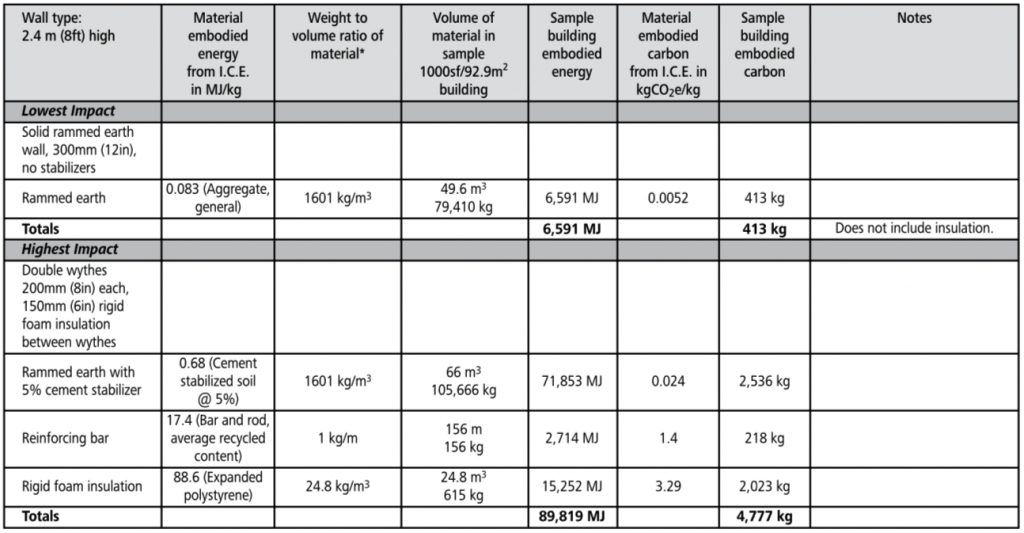

Chart of Embodied energy & carbon

Energy Efficiency: Low to high

A rammed earth wall has a lot of thermal mass and can easily be an airtight wall system, but it has no inherent insulation value (see Thermal Mass vs. Insulation sidebar). The overall energy efficiency of a rammed earth wall system will depend on the insulation strategy. Insulation can be placed on either the interior or exterior of the wall or a double wythe system can have insulation in the middle of the wall.

Insulation on either side of the wall will force a builder to create a finished surface over the insulation, which adds cost and complexity to the wall system and isolates all of the available thermal mass on one side or the other. Core insulation is more effective and leaves the rammed earth as the finish on both sides, but complicates the forming and tamping process and limits choice of insulation to materials that can resist the compressive forces of the tamping process.

Material costs: negligable to moderate

Components for good rammed earth may be sourced on site at negligible cost, but pre-mixed versions with Portland cement stabilizers may be moderately expensive. The addition of rigid foam insulation between two wythes of rammed earth will raise costs considerably.

Labour Input: High to Very High

Rammed earth construction is labor intensive. The use of machinery can reduce the amount of labor involved in excavating, mixing and tamping earth, but even machine time can be extensive. Building, erecting and disassembling formwork takes a lot of time regardless of tamping method. However, when used as the finished wall surface, a rammed earth wall eliminates the need for steps often required to sheath and finish other walls.

Skill level required for homeowners: moderate

Mixing and tamping soil does not require prior experience, but the creation and use of formwork does, as does the operation of excavation and dirt-moving machinery. A first-time builder will want some training or experience prior to undertaking a major rammed earth project.

Sourcing & availability: Easy to moderate

Soils suitable for rammed earth construction are widely available, as are the ingredients for amending soils that are not inherently suitable. The equipment used for excavating and tamping earth is common to other more conventional construction activities and should be easy to source.

Insulation materials will vary in availability depending on type and location.

Durability: moderate to High

Rammed earth buildings have a long history in many parts of the world, with some examples lasting well over a thousand years. Erosion and/or spalling caused by excessive wetting are the main causes of failure. Creating adequate roof overhangs and site drainage can control this. Water repellents are sometimes mixed into the rammed earth or applied over exposed surfaces. These must not affect the strength of the mix or overly reduce permeability. Plasters and other forms of siding can also prevent moisture damage.

Rammed earth, like all soil-based construction types, can be repaired quite easily if damaged, by the addition of new soil mix.

Code compliance

Rammed earth construction is an accepted solution in some building codes, in regions where the technique has historical precedent. A good deal of testing and modeling of rammed earth walls has been done around the world, and the available data is usually sufficient to justify the use of rammed earth as a load-bearing wall for one- and two-story structures. A structural engineer may be needed to approve drawings to obtain a permit.

Indoor air quality: high

Uncontaminated earth is generally agreed to have no inherently dangerous elements and is consistent with the aims of high indoor air quality.

Soil contamination, from natural sources like radon or synthetic sources like petrochemicals, is possible, and it is wise to inspect and/or test soils carefully before using them to build a house.

Resources for further research

Walker, Peter. Rammed Earth: Design and Construction Guidelines. Watford, UK: BRE hop, 2005. Print.

Easton, David. The Rammed Earth House. White River Junction, VT: Chelsea Green, 1996. Print.

Minke, Gernot. Earth Construction Handbook: The Building Material Earth in Modern Architecture. Southampton, UK: WIT, 2000. Print.

Rael, Ronald. Earth Architecture. New York: Princeton Architectural Press, 2009. Print.

Morton, Tom. Earth Masonry: Design and Construction Guidelines. Bracknell, UK: IHS BRE, 2008. Print.

Jaquin, Paul, and Charles Augarde. Earth Building: History, Science and Conservation. Bracknell, UK: IHS BRE, 2012. Print.

Keefe, Laurence. Earth Building: Methods and Materials, Repair and Conservation. London: Taylor & Francis, 2005. Print.

McHenry, Paul Graham. Adobe and Rammed Earth Buildings: Design and Construction. Tucson, AZ: University of Arizona, 1989. Print.

Future development

Code development for rammed earth is moving forward in several countries, including the US and Australia. Widespread code acceptance is likely to encourage more rammed earth construction.

As the basics of rammed earth construction have remained the same for thousands of years, revolutionary developments in technique are unlikely. However, processes to reduce labor input for formwork and soil mixing and tamping are likely to be streamlined, making the system more affordable.

Tips for a successful rammed earth wall

1. Formwork is the key to building with rammed earth, and the better the formwork the faster and more accurate the construction. Forms must be able to withstand the considerable forces of ramming the earth within and be able to be assembled and disassembled with a minimum of effort. Formwork that is reusable can help keep costs down. Check with experienced builders to see what formwork systems are being used successfully.

2. Soils used for rammed earth must be very well mixed and not too wet. An even distribution of clay and any additional binders (cement, slag, lime, fly ash) is crucial to final wall strength. Rammed earth mixes do not benefit from the plasticity that water adds, and require plenty of mechanical mixing to achieve best results instead.

3. Test potential soils before using. The makeup of the soil is critical to the performance of the wall. A lot of soil is required to make a rammed earth wall, and changes in its composition will mean that mixes may need to change too. Compact samples of the earth and use reliable sources to determine whether or not you will need stabilizers, and which ones are most appropriate for the soil type.

4. Plan mechanical systems and wall openings carefully, as modifying rammed earth walls is time-consuming. If services are to be run within the walls, consider using conduit so that you can make changes and repairs without opening the wall.

5. Avoid finishes that will reduce or eliminate the permeability of the rammed earth wall.

6. If you are building your own home, consider buying the equipment you will need to dig, mix and tamp the earth. It can be much less costly to buy used equipment and re-sell it at the end of a project than to rent it for a long period of time.