cellulose

Insulation: MATERIALS ENCYcLOPEDIA

Applications for this system

Wall cavities (wet-sprayed or dry dense-packed only)

Wall cavities (wet-sprayed or dry dense-packed only)

Basic materials

Shredded recycled newsprint

Borax as a fire retardant (some manufacturers also use ammonium sulfate)

Proprietary mold-inhibitors (usually chlorine-based) for wet-sprayed cellulose

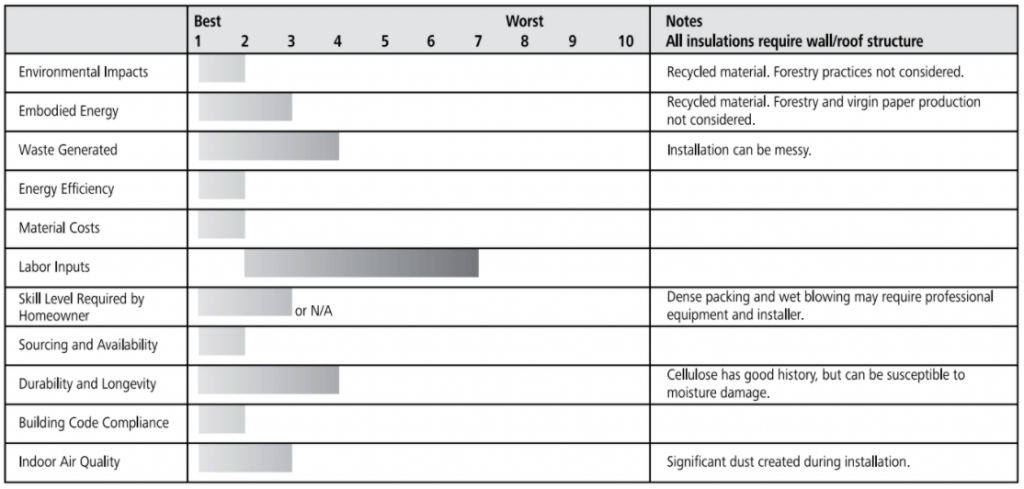

Ratings Chart for Cellulose insulation

The ratings chart shows comparative performance in each criteria category. Click on the tabs below for detailed analysis of each criteria.

- HOW THE SYSTEM WORKS

- ENVIRONMENTAL IMPACTS

- WASTE

- EMBODIED CARBON

- ENERGY EFFICIENCY

- MATERIAL COSTS

- LABOUR INPUT

- SKILL LEVEL REQUIRED

- SOURCING & AVAILABILITY

- DURABILITY

- CODE COMPLIANCE

- INDOOR AIR QUALITY

- RESOURCES

- FUTURE DEVELOPMENT

cellulose System

Wet-sprayed cellulose

The cellulose insulation is mixed with a small amount of water as it is sprayed into wall, ceiling and/or floor cavities using a purpose-made sprayer. The mix has similar properties to papier-maché and adheres in cavities to form a semi-solid, dense insulation. The insulation needs to dry for several days after installation; excess insulation is trimmed or shaved before the cavity is closed.

Dry-blown cellulose

The cellulose insulation is blown through a purpose-made hopper/blower and placed on any horizontal ceiling or floor cavity. Dry-blown cellulose for wall cavities must be dense-packed to at least 3.5 lbs/ft3 (55kg/m3) to prevent settling and gaps at the tops of walls. It is frequently used in renovations as it is a relatively easy material to insert into existing wall cavities.

Environmental Impact Rating

Harvesting — Low

Cellulose insulation is largely composed of shredded recycled newsprint. Much of this material is recycled from industrial sources, though some brands feature high quantities of post-consumer material.

Manufacturing — Low

Newsprint is shredded using relatively low-impact mechanical equipment.

The fire retardants used in cellulose insulation are typically borates, which are mineral-based and relatively low in environmental impacts.

The chlorine-based mold inhibitors used in some wet-sprayed brands can be toxic in their manufacture, though they are used in very small quantities.

Transportation — Low to Moderate

Sample building uses 1,056 – 1,736 kg of cellulose:

1.6 – 2.6 MJ per km by 15 ton truck

1 – 1.6 MJ per km by 35 ton truck

Products are widely produced and should not need to travel far.

Installation — Moderate

Cellulose installations tend to be messy and dusty and the blowers require high current electricity.

Waste: Low to moderate

Recyclable – Plastic packaging

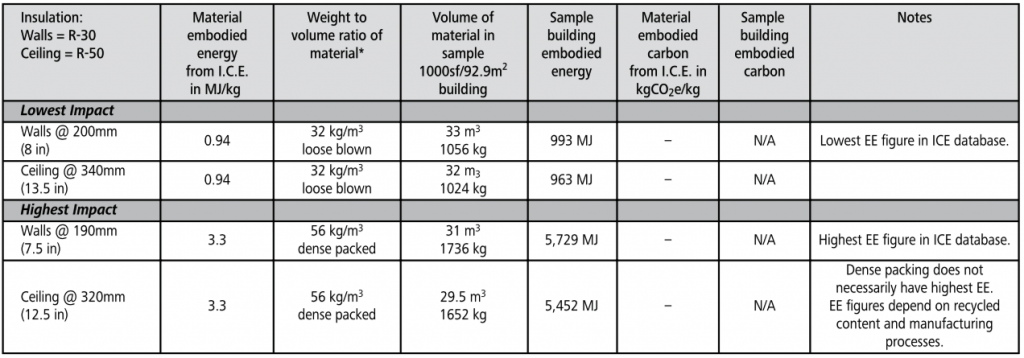

Chart of Embodied energy & carbon

Energy Efficiency

R value: 3.6–4.0 per inch

Wet-sprayed cellulose provides a reasonable degree of air control in the wall cavity, though it is usually advisable to rely on an additional air control layer to provide a well-sealed wall. Dry-blown cellulose must have an additional air control layer.

Sprayed or blown cellulose are good at filling cavities and conforming to obstacles like plumbing and wiring.

Dry-blown cellulose that is not densely packed will settle over time, which is not problematic on flat surfaces like ceilings but will leave gaps at the tops of wall cavities and cause reductions in thermal performance. For this reason, dense-packing techniques should be used for walls.

Material costs: Low

Cellulose is among the lowest cost insulation materials, often less expensive than other mainstream competitors.

Labour Input: moderate to High

A commercial installer must be hired to install wet-blown or dense-packed cellulose. Homeowners can install loose dry-blown varieties, and the process requires two people: one to feed the cellulose bales into the shredder/hopper and the other to manage the blower hose.

Skill level required for homeowners

Dry-blown cellulose: easy to moderate

Requires little training or experience to install.

Wet/dense-packed cellulose: n/a

must be done by a professional with the proper equipment.

Sourcing & availability: Easy

Dry-blown cellulose is widely available and most suppliers of the insulation also supply the installation machinery. The availability of installers for wet-blown cellulose varies widely by region.

Durability: moderate to High

Both types of cellulose insulation have been widely used for several decades. The main durability issue comes from excessive wetting of the insulation, which can cause loss of thermal performance, settling and potential for mold growth. Kept dry, cellulose insulation has shown itself to be very durable.

Code compliance

Most building codes accept both wet-sprayed and dry-blown cellulose. Sufficient testing documents exist to show code equivalency where codes do not include cellulose.

Indoor air quality: moderate to high

Wet-sprayed cellulose can sometimes contain chlorine-based mold inhibitors. These would be most present in the air during and shortly after installation, but should be avoided if chlorine is on your red list. Check with manufacturers for exact ingredients.

Dry-blown cellulose creates a lot of dust when installed, and the house should be cleaned well before occupancy. If the building’s air/vapor control layers are well built, there should be minimal intrusion of dust into the building. However, leaks in these layers could result in cellulose dust being drawn into the building when occupied.

Both types of cellulose insulation are capable of storing a lot of moisture safely, but because the cellulose is a good medium for mold growth, excessive moisture can potentially lead to mold issues.

Resources for further research

n/a

Future development

Wet-sprayed

Despite its many positive aspects, wet-sprayed cellulose has seen a decrease in market share with the recent popularity of spray foam insulation. This is unfortunate, as it has far fewer environmental and health issues and can create a vapor-permeable wall system. The drying time is a drawback for contractors moving quickly to close in buildings. Many installers who now apply spray foam used to apply wet-sprayed cellulose and may still be able to do so, even if they are not advertising the service.

Dry-blown

Due to its user-friendly nature, dry-blown cellulose is very popular for insulating attic spaces and for insulating walls in retrofits. The basic makeup of the material has been the same for decades and is unlikely to change in nature or decrease in popularity. High-pressure dense-packing machinery is relatively new and opens up more possibilities for dry cellulose in new construction.

Both types of cellulose are rare examples of environmentally friendly building materials that are already widely used in the conventional building industry.

Tips for successful cellulose insulation

1. Professionals with the proper equipment install wet-sprayed cellulose.

2. Homeowners, using a blower rented from the insulation supplier, can install loose, dry-blown cellulose for attics, but professional equipment is needed for dense packing in wall cavities.