Finger-jointed Wood Trusses

Floor & Roof Structure: MATERIALS ENCYcLOPEDIA

Applications for this system

Floor and roof framing

Basic materials

Small dimension solid lumber (2×2, 2×3, 2×4) with finger-jointed ends

Glue at finger jointed connections

OSB in some systems

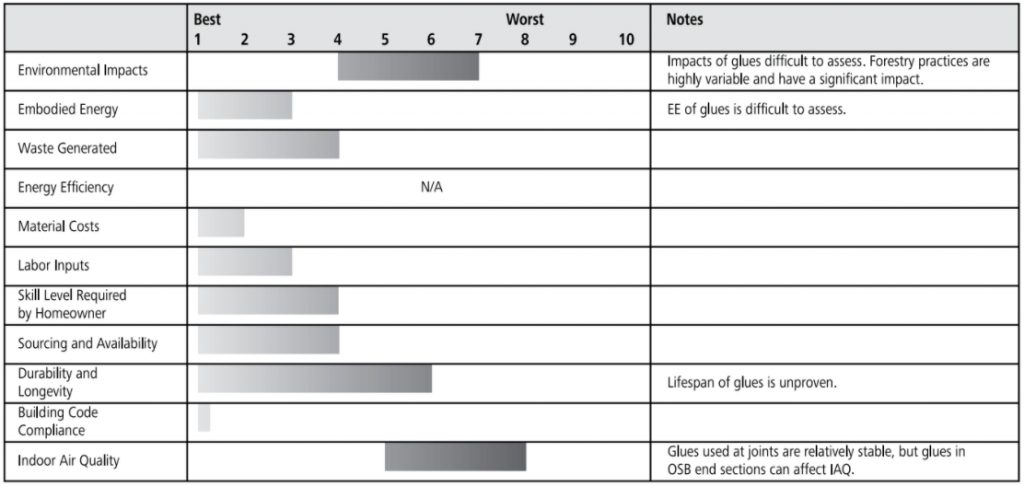

Ratings Chart for finger-jointed wood truss floor or roof

The ratings chart shows comparative performance in each criteria category. Click on the tabs below for detailed analysis of each criteria.

- HOW THE SYSTEM WORKS

- ENVIRONMENTAL IMPACTS

- WASTE

- EMBODIED CARBON

- ENERGY EFFICIENCY

- MATERIAL COSTS

- LABOUR INPUT

- SKILL LEVEL REQUIRED

- SOURCING & AVAILABILITY

- DURABILITY

- CODE COMPLIANCE

- INDOOR AIR QUALITY

- RESOURCES

- FUTURE DEVELOPMENT

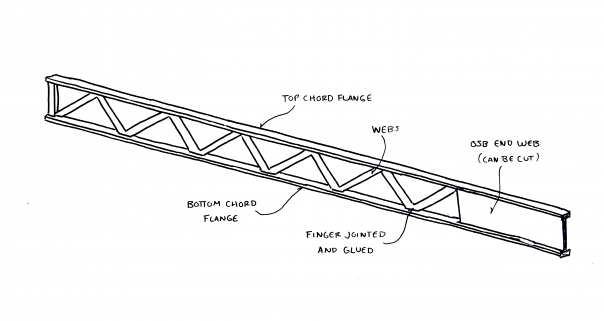

Finger-jointed wood truss System

An open web joist is created using solid-lumber top and bottom cords that are finger-jointed to accept solid lumber webbing. These open web joists can be customized to a particular length, or can be made with a short section of OSB (identical to the wooden I-beams described earlier) to allow for custom sizing on-site.

An open web joist is created using solid-lumber top and bottom cords that are finger-jointed to accept solid lumber webbing. These open web joists can be customized to a particular length, or can be made with a short section of OSB (identical to the wooden I-beams described earlier) to allow for custom sizing on-site.

Truss joists are ordered at the appropriate lengths for the project and different depths are available to handle particular spans and loads. Suppliers provide engineering to ensure that appropriate depths and spacing are matched to loads and spans.

Truss joists do not exhibit the same tendencies to warp, split or otherwise distort that are common with solid timber joists.

The open webbing of the truss joists allows for easy routing of plumbing, wiring and heating services.

Environmental Impact Rating

Harvesting — Negligible to High

Unmanaged forestry can have impacts that include significant habitat destruction, soil erosion and ground water contamination. Third-party certification can help to ensure that impacts are minimized. Finger-jointed wood can make use of marginal wood in short lengths.

Metal fasteners may seem like a small component, but dozens of kilograms can go into a frame wall. Ore for steel production is mined in an intensive process with impacts including habitat destruction and soil and water contamination.

Glues for finger jointing are petrochemical based.

Manufacturing — Negligible to Moderate

The sawing and planing of structural lumber is a relatively low-impact mechanical process.

Processing raw ore into nails and screws is a multi-stage and intensive process requiring multiple infusions of high heat and fossil fuel use with impacts including air and water pollution.

Glues can have impacts including significant air and water pollution.

Transportation — Negligible to High

Sample building uses 2,229.4 kg of finger jointed trusses for roof and floor:

3.35 MJ per km by 15 ton truck

2.1 MJ per km by 35 ton truck

Timber is a heavy and high-volume material and accrues significant impacts proportional to distance traveled. Regional manufacturers are accessible to many markets.

Installation — Negligible to Moderate

The number of offcuts from a truss joist are typically minimal, as joists are ordered to size.

Waste: Low to moderate

Compostable -Wood offcuts with no glue

Recyclable – Metal fasteners

Landfill – Offcuts with glue

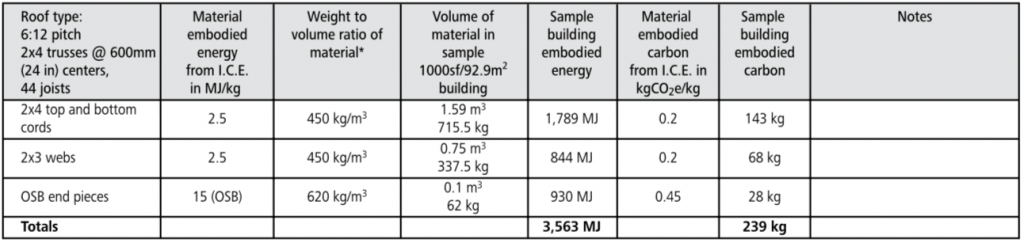

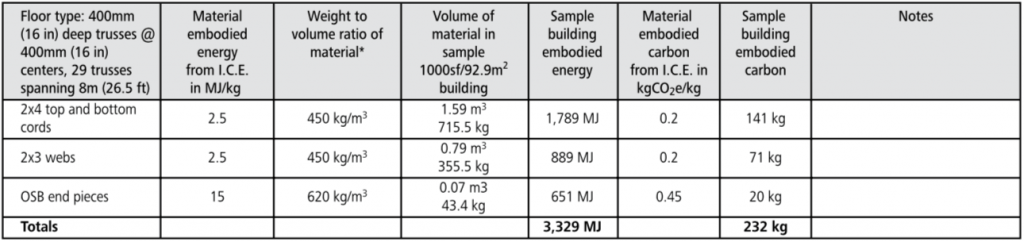

Chart of Embodied energy & carbon

finger-jointed wood truss roof:

finger-jointed wood truss floor:

Energy Efficiency

Open web wood joists are typically deeper than comparable solid lumber joists, offering more depth for insulation. The webbing in the joists is not continuous, but does create very small cold bridges through the insulation. Properly filled with insulation, a roof and/or floor system built with open web wood joists can be part of an energy-efficient building enclosure.

Material costs: Low

Finger jointed trusses are not custom-built for each application, but come in standard lengths and are designed to be trimmed to an appropriate length on site. This allows them to be mass produced and typically provide the lowest cost option for floor and roof framing.

Labour Input: low to moderate

One of the main benefits of manufactured joists is that they are lightweight, making it possible for one or two workers to handle very long spans of joist. The ability of the joists to span greater distances can also reduce labor time as it eliminates joints. Longer spans can also reduce the number of load-bearing walls required in a design, eliminating labor throughout the building process, from the foundation upward.

Open web joists leave plenty of room for installers to run plumbing, electrical and heating runs, which can help to reduce labor time for these trades.

Skill level required for homeowners: low to moderate

Any builder able to frame a floor or roof with solid lumber will be able to do the same with truss joists. The joists come pre-engineered, and will include layout drawings that should be easy for newcomers to follow. Beginners will need to understand basic carpentry skills. Often, truss joists are delivered at the required lengths, reducing the number of cuts to be made on-site.

Sourcing & availability: Easy to moderate

Open web wooden joists are widely available, usually through building supply centers. An in-house designer and/or engineer will work from a set of plans to determine the depth of joist required and a suitable layout.

Durability: moderate to High

The finger jointed and glued connections of these joists have proven to be very stable, but they have not yet withstood the test of decades. The glues are not susceptible to water in the same way as OSB glues. They achieve suitable fire ratings for residential and commercial use, but may not last as long in a fire as solid lumber.

In regular usage, these joists can be part of a durable structure.

Code compliance

As this is a pre-engineered system, it is a widely accepted solution in most jurisdictions. Building departments will typically want to be provided with a signed, stamped version of the joist drawings as part of the plan submission package.

Indoor air quality

Open web wood joists installed as roof framing are typically outside the building enclosure and should have no effect on IAQ. The IAQ impact of the glues used at the finger joints are difficult to assess without knowing the contents. Several manufacturers claim that their glues are healthy and have no impact on IAQ, but this is not a guarantee, and proprietary recipes make it difficult to assess the glues.

Resources for further research

n/a

Future development

A growing number of manufacturers offer FSC or other third-party certified wood sources, and this trend is likely to grow as awareness of certified wood increases. Many manufacturers are working to make their glues more environmentally sound.

Tips for a successful finger-jointed wood truss floor or roof

1. Open web joists are proprietary products, and each manufacturer will have its own installation guidelines that should be followed closely.

2. Open web joists cannot be cut or altered except in those places specified by the manufacturer. If site conditions require alteration, ensure that the manufacturer approves any changes.