Natural Oils & Waxes

Finishes: MATERIALS ENCYcLOPEDIA

Applications for this system

Raw wood, plaster, concrete

Walls, floors, countertops, windowsills, furniture

Not suitable for use on:

– Drywall

– Metal

Basic materials

Natural, siccative (oxidizing) oil (typically cold-pressed linseed, but can be semi-siccative oil like walnut, hemp, poppy, tung, sunflower, safflower, soya and even fish oil)

Solvent thinner (typically citrus thinner or natural alcohol)

Admixtures, as required (may include pine resin, drying agents and polymerizing compounds)

Beeswax, carnuba or other natural wax

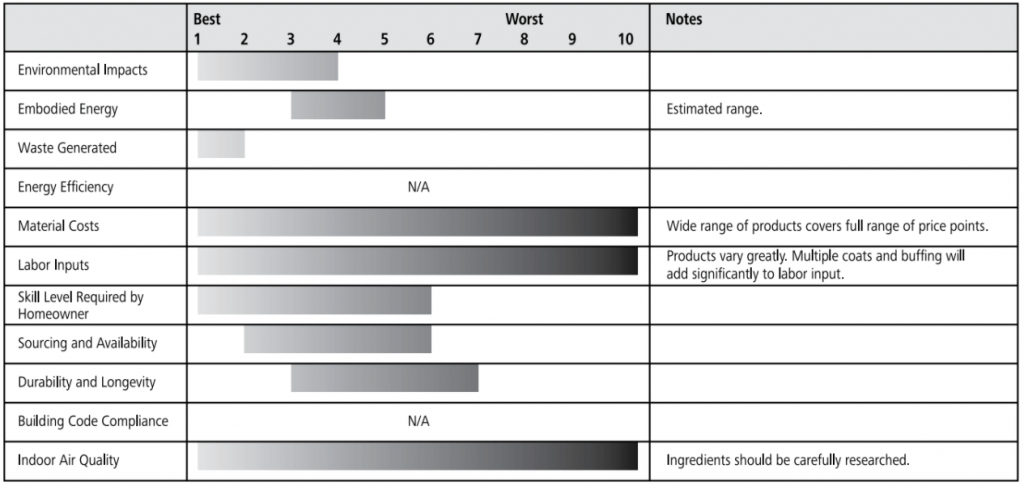

Ratings Chart for Natural oils and waxes

The ratings chart shows comparative performance in each criteria category. Click on the tabs below for detailed analysis of each criteria.

- HOW THE SYSTEM WORKS

- ENVIRONMENTAL IMPACTS

- WASTE

- MATERIAL COSTS

- LABOUR INPUT

- SKILL LEVEL REQUIRED

- SOURCING & AVAILABILITY

- DURABILITY

- INDOOR AIR QUALITY

- RESOURCES

- FUTURE DEVELOPMENT

Natural oil/wax System

Natural oil finishes are very similar to natural oil paints (see page XX), but do not contain pigments or bulking agents to add opaqueness to the finish. They are typically a clear coat used to enhance the natural color of the substrate, or are lightly tinted to accent the substrate color.

Oils for finishes may be pure oil or a blend of oils and waxes formulated to provide desired characteristics. There are many such blends, and their intended use should be researched before committing to use of a particular blend.

Some oil finishes are referred to as “hard oils.” This refers to a lack of solvents or thinners in the mix, and not necessarily to a more solid or durable surface.

Raw oils used on surfaces will take a very long time to dry, and if applied too thickly may never completely harden. Most oils are blended for best drying characteristics, or are polymerized during production to speed curing times.

Oils are sometimes blended with waxes in a single product, but more often wax is applied to an oiled surface. In both cases, wax helps provide water repellency, shine and flexibility to the finish. There are many types of natural waxes, but the majority of commercially available waxes are either blends of natural wax and petrochemical wax, or fully petrochemical.

Environmental Impact Rating

Harvesting — Low to Moderate

Natural oils are pressed from seeds. Seed crops are grown in a wide variety of manners all over the world, from small-scale organic to factory farms. Some oil-bearing seed crops (flax and hemp, in particular) also bear useful fibers in their stems, resulting in a harvest with very little waste. Impacts will vary greatly, and can include habitat destruction, pesticide and herbicide runoff and soil depletion.

Natural wax harvesting, whether from bees or from plants, is a relatively low-impact process. Beehives and wax-bearing plants are not typically destroyed in harvesting, as they can continuously regenerate wax.

The two most common types of natural solvents are turpentine and citrus solvent. Turpentine is distilled from pine resin, with relatively low impacts from harvesting. Products called citrus thinners can have a range of ingredients, from pure citrus oil (extracted from lemon, orange and/or grapefruit rind) to blends of citrus oil, mineral oil and herbal essential oils. Citrus growing can have significant impacts, including high pesticide, fungicide and herbicide use. However, the fruit rind is a secondary product of citrus farming, and its use helps to reduce waste.

Manufacturing — Low

Cold-pressing of seed oils is a low-energy and low-impact mechanical process.

Natural wax manufacturing involves the use of very low amounts of heat input and is otherwise a very low-impact process.

The distillation of turpentine and extraction of citrus oil are both low-energy, low-impact processes. Most manufacturers now recapture emitted VOCs, which are the most detrimental impact.

Transportation — Low to High

Oil-bearing crops grow in almost every region, but centralized production may mean that oils have traveled long distances. Beeswax is produced in many places around the world, and wax may be imported from regions with low wages. Carnauba wax is harvested only in Brazil.

Installation — Negligible

Oily rags from application or cleanup can be combustible and must be treated with care to prevent fire.

Waste: Negligible

Biodegradable/Compostable — Natural oil finishes are made with all-natural ingredients, but they are not well suited to biodegradation at a household level. The oils will remain sticky and persistent for a very long time, creating problems in compost piles or in the soil.

Recyclable — Containers.

Hazardous Waste — Oil finishes that cannot otherwise be used should be sent to a hazardous waste facility.

Material costs: Low to high

A wide range of products are manufactured at different price points.

Labour Input: low to High

Application procedures and number of required coats will vary by product. Typically, application labor will be similar to painting. Wax applications require application and an intensive buffing process.

Health Warnings

Solvents in some oil finishes can be toxic. Read labels carefully for warnings.

Skill level required for homeowners

Mixing of finish — Easy to Moderate

A simple oil finish may require no mixing. More complicated formulations may require heating and special blending techniques.

Preparation of substrate — Easy

Application of finish — Easy to Moderate

Oils are typically brushed onto a surface and then wiped back with a lint-free cloth to avoid pooling. Anywhere from one to three coats is common. Wax is typically applied with a lint-free cloth and then buffed or polished after some curing time.

Sourcing & availability: moderate

The individual ingredients for oil and wax finishes are reasonably easy to acquire, though they may require individual sourcing.

Commercial oil finishing products are widely available through building supply stores and furniture finishing specialty shops. All-natural formulations may be more difficult to source from manufacturers or sustainable building supply outlets.

Durability: moderate

Natural oil finishes create very flexible coatings that can expand and contract with the substrate material. This makes them ideal for coating wood, and they provide a very durable finish for both interior and exterior wood. They are water repellent and can be washed. They are easier to scratch than chemical-based paints, and will not retain a high degree of gloss if touched or rubbed. This does not affect lifespan, only appearance.

Natural oils do not resist UV light very well, and the substrate material (especially wood) can deteriorate and cause the finish to fail.

Wax is very water resistant, and can keep substrate materials well protected. Wax finishes have a low melting temperature, and can deteriorate in direct sunlight.

Additional coats of oil or wax can be applied to surfaces to maintain protection.

Indoor air quality: low to high

Natural oil finishes may have a negative impact on IAQ. Those using turpentine or chemical solvents should be avoided, as these will emit high quantities of VOCs over a long period of time. Finishes using citrus solvents will also emit VOCs, though there is evidence that these emissions are not as dangerous to human health. The chemically sensitive should research reactivity to citrus oil before using these paints.

Natural oils themselves also emit VOCs. Each oil type is different in this regard, and reactivity to various types of oil should be researched. Some people find the fragrance of natural oil paints to be pleasing, while others find it distracting or distressing.

Resources for further research

Weismann, Adam, and Katy Bryce. Using Natural Finishes: Lime- and Earth-Based Plasters, Renders and Paints: A Step-by-Step Guide. Totnes, UK: Green, 2008. Print.

Edwards, Lynn, and Julia Lawless. The Natural Paint Book: A Complete Guide to Natural Paints, Recipes, and Finishes. Emmaus, PA: Rodale, 2002. Print.

Safecoat AFM Naturals, see afmsafecoat.com/products.php?page=4

Future development

Natural oil finishes have been used for thousands of years, especially on wood, and only lost their place in the market in the past half century. There has been a slow but growing resurgence of these finishes in recent years. Advances in the availability of citrus-based solvents and oil production and polymerization have created a new breed of oil paints that don’t have many of the drawbacks of traditional versions. Advances in natural chemistry may further improve on the qualities of these finishes, and consumer demand for environmentally friendly coatings and the natural beauty of oiled wood may increase the market share.

New research is ongoing into the strengths of different mixes, which should help with code compliance issues. As the system becomes more widely used, new tools and techniques are sure to be developed that will streamline the process. Mixing and pouring concrete foundations used to involve large amounts of labor input that have, over time, been replaced with mechanical devices. The same could easily happen to earthbag foundations, making them even more attractive than they already are.

Tips for a successful natural oil or wax finish

1. Natural oils and waxes are formulated for many specific uses. Species of wood or [other type of substrate], interior or exterior use, degree of surface glossiness and tint are among the differences between products. Be sure to choose an appropriate finish for the desired result.

2. The decision to use a wax finish should be made carefully. While waxes can add luster and durability to a surface, the addition of wax makes it very difficult to change the finish in the future, as the wax will repel any new coating (except more wax). Wax finishes require maintenance to keep them buffed and lustrous.

3. Many natural oils and waxes are proprietary products. Follow the manufacturer’s instructions for successful application.