Rammed Earth Tires

FOUNDATIONS: MATERIALS ENCYcLOPEDIA

Applications for this system

Perimeter Beams

Frost walls

Piers

Basement walls

Basic materials

Used car and/or truck tires

Soil suitable for creating rammed earth

Cob or mortar to fill gaps and plaster

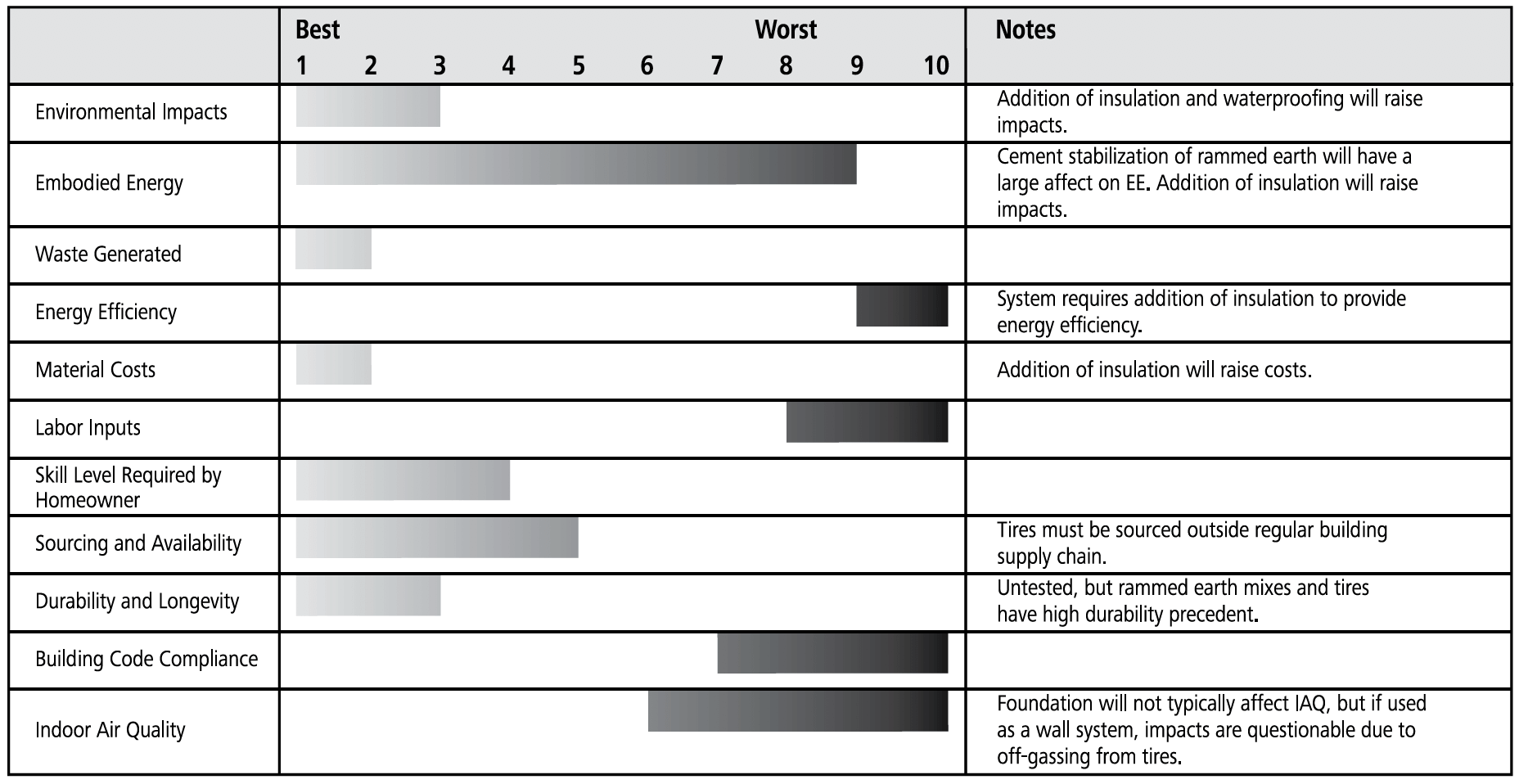

Ratings Chart for rammed earth tire Foundation

The ratings chart shows comparative performance in each criteria category. Click on the tabs below for detailed analysis of each criteria.

- HOW THE SYSTEM WORKS

- ENVIRONMENTAL IMPACTS

- WASTE

- EMBODIED CARBON

- ENERGY EFFICIENCY

- MATERIAL COSTS

- LABOUR INPUT

- SKILL LEVEL REQUIRED

- SOURCING & AVAILABILITY

- DURABILITY

- CODE COMPLIANCE

- INDOOR AIR QUALITY

- RESOURCES

- FUTURE DEVELOPMENT

Rammed earth tire Systems

Tire walls

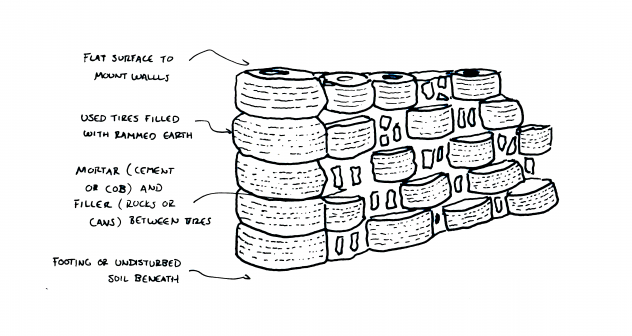

Discarded automobile and truck tires are used as permanent formwork for a rammed earth mixture. Tires of a similar diameter and width are laid side by side along the line of the foundation and filled with a soil mixture with good compressive qualities. The mixture is first distributed around the rim of the tire and compressed, typically using a sledgehammer to pound the mixture into the sidewalls. When the sides are filled, the center area of the tire receives mix that is rammed into place.

After a course of tires has been filled and tamped, the next course is laid on top with the joints between tires staggered from the course below. Using tires of the same size will help keep the foundation level as successive courses are added.

When the wall is built to its full height, the indentations where tires meet are packed with a low-cost filler to make the surface of the wall relatively straight and flush. Crushed aluminum cans or glass bottles are sometimes used in this role, but in places where these are recycled this may not be the best choice. A cob mixture with lots of straw can serve this purpose, or rocks can be mortared in with a clay or cob mix.

The finished wall can be insulated and waterproofed in a number of ways, depending on the type of wall and local conditions and codes.

The rammed earth inside the tires will wick ground moisture upwards into the wall, so a barrier of some kind will be needed to separate the wall system from the foundation or the ground. Walls can be attached by bolting sill plates or using strapping to loop beneath the tires and over the sill.

Earthships

Rammed earth tires as a building material were popularized in a form of home construction dubbed earthship. In these structures, rammed earth tires form a subgrade retaining wall for a building that is built into a berm or hillside. The tires form both foundation and wall, typically on the northerly, bermed side of the structure; on the south side they are usually only used as a foundation and knee wall, with a heavily glazed area above. Since the use of tires is so strongly associated with earthship construction, many people are not aware that tires can be used as a foundation system in other forms of construction.

Tire piers

A rammed earth tire pier foundation is built from a stack of tires laid one on top of the other. The first tire is laid on a level gravel bed below the frost line and additional tires stacked and tamped to the desired height above grade. A grid of such piers can be used to support a floor system or a grade beam. A concrete cap is often poured in the top tire to provide a solid anchor for the floor system. Alternatively, a strapping system can be wrapped under the pier to attach the floor system.

Environmental Impact Rating

Harvesting — Negligible to Low

Petrochemicals for the rubber and steel for the belting both have high impacts, including habitat destruction and air and water pollution, but as a recycled material these impacts are mitigated.

Site soil has negligible impacts.

Manufacturing — Negligible to Low

Recycling the tire as a building material mitigates high impacts from tire manufacturing.

Site soil has negligible impacts.

Transportation — Negligible to Moderate

Sample house uses 4,680 kg of tires:

7 MJ per km by 15 ton truck

4.4 MJ per km by 35 ton truck

Sample house uses 35,200 kg of fill material:

52.8 MJ per km by 15 ton truck

33 MJ per km by 35 ton truck

Tires and fill material are a high-volume materials to transport and impacts will rise proportionally with distance traveled.

Installation — Negligible to Moderate

Potential leachate toxicants from the tires entering soil and/or groundwater around the foundation may be a concern. No recognized data exists for tire foundations, as studies tend to focus on different end-uses for old tires, like track and paving compounds, playground surfaces and fish habitat. In most studies, zinc, heavy metals and vulcanization and rubber chemicals from tires are shown to leach into soils and water. What is unclear is the quantity of leachate and the effect on soil, water and living organisms. In a successful foundation the tires are typically separated from the backfill by a waterproofing membrane, which will greatly reduce contact and potential leaching.

Waste: Negligible

Biodegradable/Compostable — Soil fill, aggregate.

Recyclable — Remaining tires may be recyclable.

Landfill — Remaining tires, if no recycling program exists.

Chart of Embodied energy & carbon

Energy Efficiency: Very Low

A rammed earth tire foundation has little thermal resistance. In areas where insulating foundations is crucial, a strategy to add insulation to the inside and/or outside edge of a tire foundation will be important. With a proper insulation strategy in place, a tire foundation can be part of an energy-efficient building. The width of tires and the uneven face of the foundation can provide challenges in the use of interior or exterior insulation layers.

Material costs: Low

In some cases, people building with tires have been paid to take the tires they have used. This is one of the only examples of cost-negative construction materials! However, do not count on this being the case as recycling programs grow more common.

Labour Input: Very High

Tire foundations require a lot of labor. Individual tires are no more difficult to handle and place than any other foundation material, but the placing and tamping of the soil mixture is very laborious. The soil must be placed and compressed into the sidewall of the tire, requiring careful placement of the dirt and a ramming technique that involves applying force toward the outside edge of the tire. This does not lend itself well to mechanical placement and tamping of the dirt. The effort required to tamp sideways (usually with a sledgehammer) is higher than tamping downwards.

A typical tire holds about 140 kg (300 lb) of soil, and experienced builders report that it takes between 10–45 minutes (depending on soil conditions, height of wall and other factors) for a pair of workers to fill and tamp each tire. Beginners can take an hour or more per tire.

If the construction crew is also gathering and transporting the tires, this can add significantly to the labor requirements.

Mechanical equipment can lower the amount of manual labor involved, but the need to carefully place the dirt in each tire ensures that there will still be a high amount of labor input.

Health Warning:

Sand, silt, clay and dust can be harmful to your lungs. Wear adequate respirators when dealing with dusty materials. It is also advisable to wear gloves and respirators while handling tires.

Skill level required for homeowners: Easy

A tire foundation is quite easy to build. As with any type of foundation, the layout is critical. Beyond the layout lines, people with little or no construction experience can learn the actual mixing, filling and tamping of the tires very quickly. Builders with a lot of experience will likely make a better, more consistent foundation more quickly. However, a dedicated group of amateurs can quickly come up to speed and within a short time could be moving as quickly and accurately as the pros.

It definitely helps to have at least one experienced tire builder on a crew. One person can usually direct an entire crew until everybody gets the pacing and methodology. If nobody has previous experience, it’s worth looking into workshops or other training opportunities before commencing with a foundation.

Sourcing & availability: Easy to moderate

Tires are an abundant waste product almost everywhere in the world. In theory, used tires are easy to find and access. However, some regions have instituted strict regulations about used tire handling and storage, often in conjunction with tire recycling programs. In these locations there are still lots of tires around, but they may be more difficult to obtain. Check into availability and local regulations about buying, selling and storing tires before committing to this type of foundation.

The dirt for placing in the tires should be widely available, and the wide range of acceptable soil types should mean that soils from the building site are viable. Inspect site soils prior to construction; if not suitable it should be possible to locate useful soil nearby.

Durability: High to Very High

The elements of a tire foundation are both very durable. Tires are a persistent waste specifically because they do not break down quickly. UV radiation does break them down slowly, but hidden from the sun they have a very long lifetime. Best estimates range from hundreds to thousands of years. The rammed earth in the tires has an immeasurable durability. Examples of tire foundations are at most a few decades old, but there is no reason to think that these foundations won’t be among the most durable it is possible to build.

Code compliance

Tire foundations are not an accepted solution in any codes. Alternative compliance will need to be based on a structural engineer’s calculations, as very little study has been done on tire foundations.

It is highly advisable to discuss the tire foundation option with code officials and find out whether or not they are willing to consider it, and under what conditions, before proceeding with plans to use tires.

Indoor air quality: n/a

Tire foundations will have little direct impact on indoor air quality. By keeping the floors and walls of the building dry they can help to prevent other IAQ issues.

When used as the walls of a building, there are concerns about off-gassing of compounds from the tires. No scientific studies have been performed to date, and advocates point to the fact that tires are sealed behind plaster or other interior wall skin to alleviate concern. Detractors question the effectiveness of the barriers.

Resources for further research

Reynolds, Michael E. Earthship: How to Build Your Own. Taos, NM: Solar Survival Architecture, 1990. Print.

Reynolds, Michael E. Earthship: Evolution beyond Economics. Taos, NM: Solar Survival Architecture, 1993. Print.

Reynolds, Michael E. Earthship: Systems and Components. Taos, NM: Solar Survival, 1991. Print.

Reynolds, Michael E. Earthship: Engineering Evaluation of Rammed-Earth Tire Construction. S.l.: S.n., 1993. Print.

McConkey, Robert. The Complete Guide to Building Affordable Earth-Sheltered Homes: Everything You Need to Know Explained Simply. Ocala, FL: Atlantic, 2011. Print.

Reynolds, Michael. Comfort in Any Climate. Taos, NM: Solar Survival, 2000. Print.

Hewitt, Mischa, and Kevin Telfer. Earthships in Europe. Watford, UK: IHS BRE Press, 2012. Print.

Future development

Tire foundations have not had much mainstream acceptance, due in large part to the labor intensity of the system. There are ways in which the system could become more mechanized, particularly in the filling and tamping of the dirt into the tires. Pneumatic devices already used in other styles of construction have been adapted to this use, though they aren’t commercially available.

Tire foundations would need a much wider acceptance before significant advancements are made in material availability and mechanization. Until then, owner-builders and custom contractors aiming for the highest standards in recycled materials will continue to use tire foundations.

In recent years, government-sponsored tire recycling programs have grown in number. Choosing to reuse old tires to build foundations seems like a reasonable way of repurposing this waste material, but builders may find themselves in competition with mandatory recycling programs in some areas.

Tips for a successful rammed earth tire foundation

1.Calculate the number of tires you’ll need and source them early. Be sure you can collect enough tires of a similar size. Though used tires are abundant, if you need hundreds you may have to go to multiple sources.

2.Check with local regulations regarding storage of tires. In many municipalities, it is illegal to have more than a small number of tires on a property. This may require bringing tires to site in batches.

3.nsure that your soil has suitable compaction qualities. In the best-case scenario the excavated site soil is compactable. Very rocky or very sandy soil can be problematic. Because the tire form stays in place, the soil does not need to be able to harden as it would in a traditional rammed earth wall.

4.Assess the amount of time it will take to build the tire foundation properly. If all the work is being done manually, this can be one of the most labor-intensive styles of foundation.

5.Plan for proper drainage around the foundation. It can be difficult to waterproof a tire foundation and sufficient drainage will help the foundation stay dry.

6.Insulation details must suit the unevenness and width of the tire foundation.

7.If the wall above is much narrower than the tire foundation, plan for details where the floor meets the wide foundation and/or where the width will leave a ledge on the outside edge of the wall.

8.Plan for proper moisture barriers and attachment systems for walls/roofs mounting to the tire walls.