One of the most exciting elements of the Circle Organic farm project is the home-made hydraulic lime plaster we successfully used on the interior and exterior walls of the building. With this new recipe, we are able to make a plaster with locally sourced materials that has a quick hydraulic set and is not affected by erosion or wear due to rain, as can happen with clay plasters.

Natural hydraulic lime (NHL) plasters are made from limestone deposits in which a significant amount of pozzolanic material is naturally occurring in the limestone. These limes come from large deposits in France, and to a lesser degree, Portugal. These limes can be purchased in North America, but are very expensive and it is carbon-intensive to ship heavy materials from overseas. Home made hydraulic lime plasters use the more commonly available hydrated lime available at masonry outlets, to which a pozzolan is added.

We have attempted to mix our own pozzolans with lime in the past, with mixed and mostly disappointing results. But the metakaolin we have sourced from Poraver for our sub-slab insulation and foundations is a very high quality and consistent pozzolan, fired to a high temperature and well-graded for a very reasonable cost.

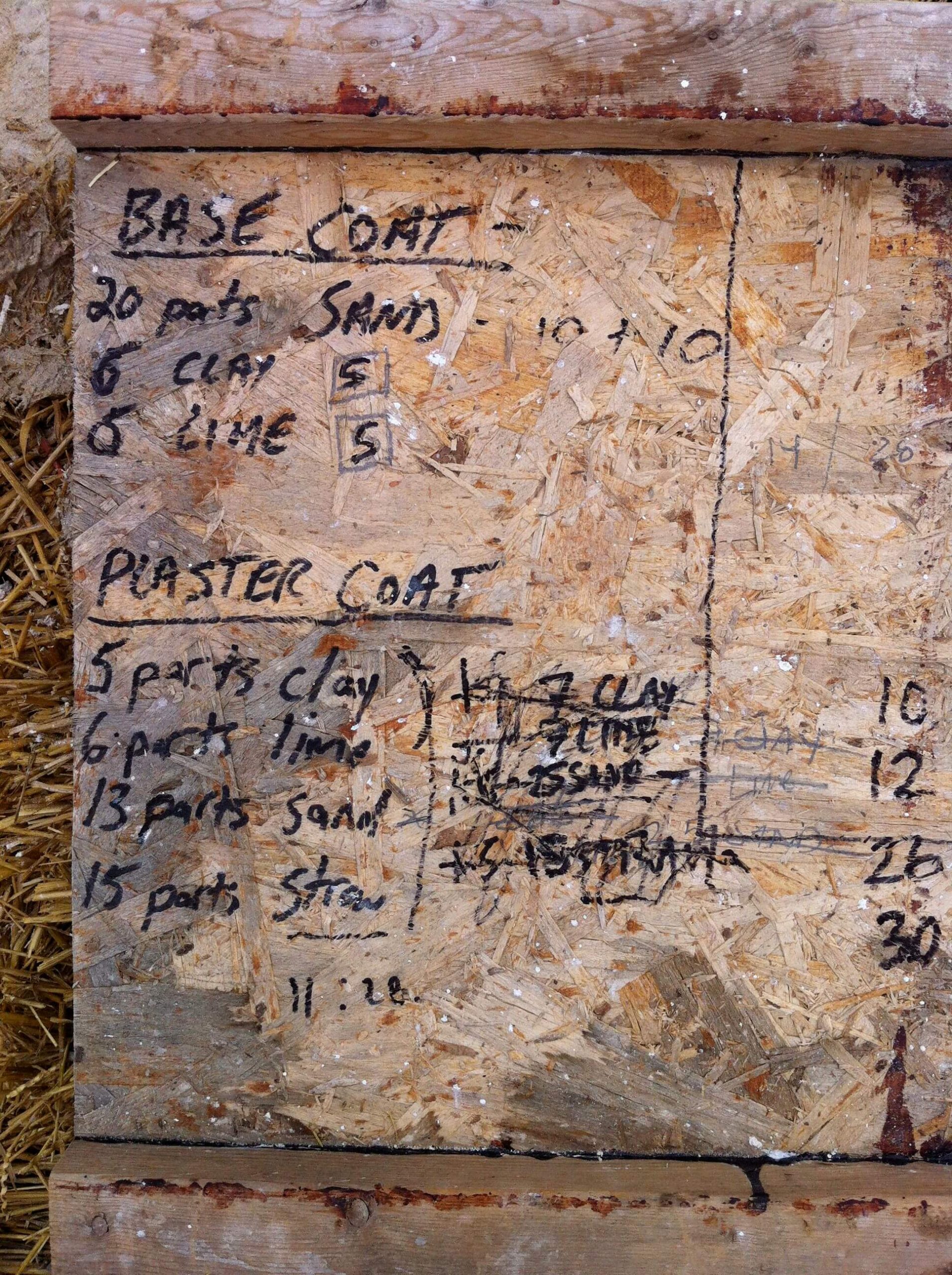

As with the Poraver foundation, we mix the metakaolin and lime in even quantities, and use this binder as the basis for the plaster. We first mix up a batch that is 1 part metakaolin, 1 part hydrated lime and 3.5-4 parts sand. This “push-in” mix is made quite thin and wet, and is used to quickly push into the straw bales by hand or trowel because it adheres very well to the straw. We then immediately cover this with a mix that is 5 parts metakaolin, 6 parts hydrated lime, 13 parts sand and 15 parts chopped straw. This coat is applied by hand until it has been built up to the right thickness, and then smoothed out with a magnesium or wood float. This provides a smooth surface that can suffice as a final finish, but also leaves a slightly textured surface in case a final, thin finish coat is desired.

The metakaolin/lime/sand mix can be used as a plaster on smoother substrates without the use of chopped straw. We plastered the Durisol block walls on the project with this type of plaster. Such a mix could be used over a wide variety of wall types, and also used as a final finish coat over the chopped straw mix.

Home made hydraulic lime plaster has several advantages over our typical clay plasters. The hydraulic set happens quite quickly, with the plaster being hard to the touch within 24 hours. This is slower than cement-based plasters, leaving more working time and being more forgiving, but much faster than clay plasters which must dry out, often over several days or weeks. The hydraulic lime plaster is not affected by water once it has set, so the plaster can handle driving rains and repeated wettings without erosion, unlike clay plaster.

While clay plasters are safer (lime can burn skin, lungs and eyes) and more environmentally friendly (lime and metakaolin both require high temperature firing), this home made hydraulic lime uses an industrial by-product (Metapor) that is sourced locally to create a plaster that has all the weather resistance of cement-based plasters without relying on cement.

For a project like the Circle Organic farm building, where conditions are exposed on the exterior and involve lots of veggie washing and other wet activities inside, home made hydraulic lime plaster is an affordable and quite sustainable plaster that will withstand rugged, wet conditions.