The Zero House project has three key goals: zero net energy use, zero toxins and zero carbon footprint. This blog will look at the notion of zero carbon footprint, and we’ll explore how Zero House will in fact far surpass this goal through carbon sequestration in building materials.

The notion of the embodied carbon footprint of buildings has not received much attention in the past. Even now, it’s not a consideration within any of the major green building rating systems and is not a key goal in very many sustainable building projects. But if climate change is a concern, addressing the embodied carbon within building materials may be the most important issue a designer or builder can address.

During the harvesting, processing and manufacturing of building materials, there are always greenhouse gas (GHG) emissions associated with these activities. Fuel is consumed, chemical processes unleashed and resources expended to create any building material. However, some materials have very high GHG emissions and others are very low. Typically, materials processed using a lot of heat and/or electrical energy will have higher embodied carbon than those with less intensive processing requirements. Good examples of this can be found in the open-source database called Inventory of Carbon and Energy Version 2.0, which provides amalgamated data for a wide range of building materials. Companies are also starting to produce Environmental Product Declarations (EPDs) that are third party analyses of a range of environmental impacts of particular products, including embodied carbon.

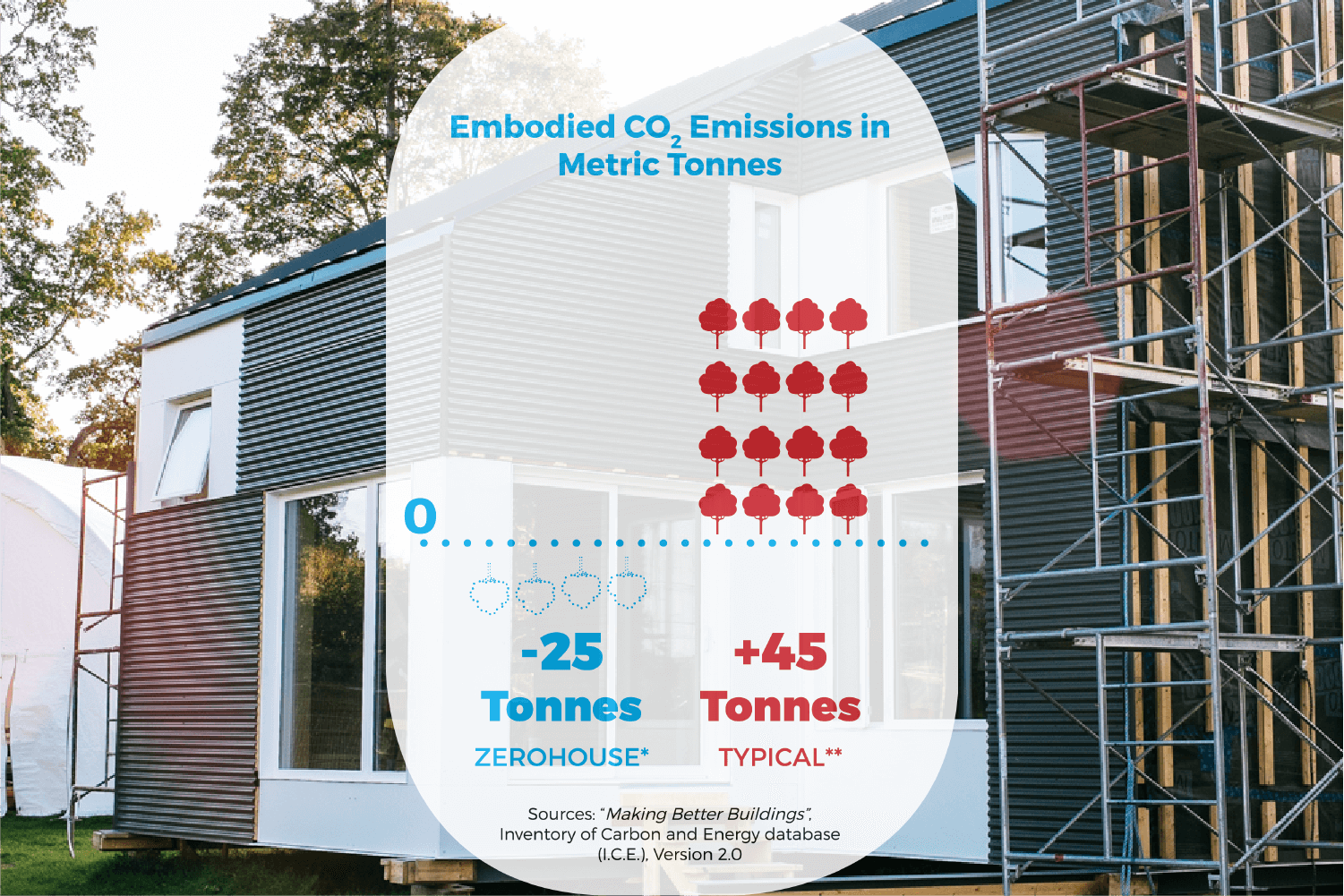

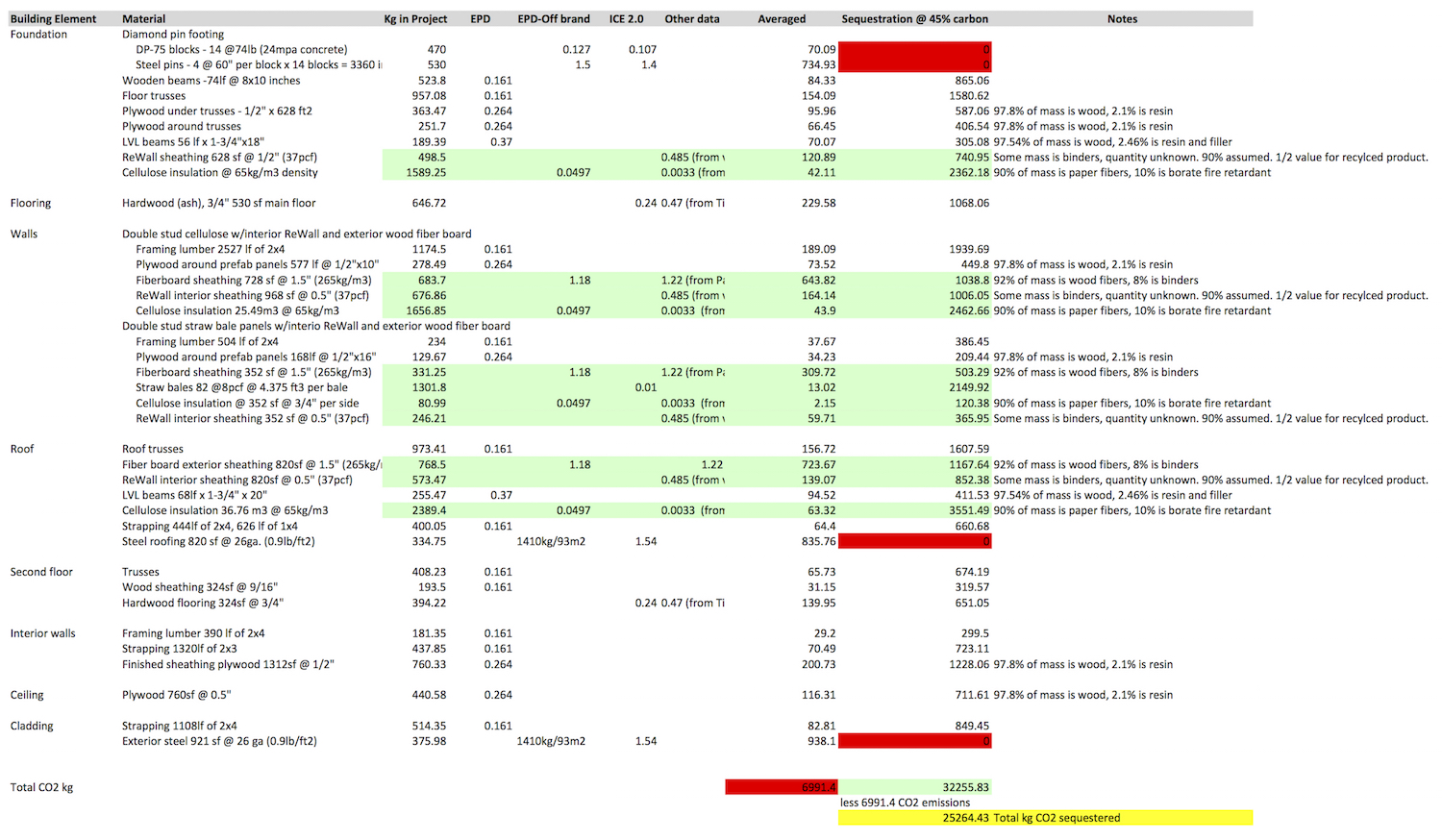

Calculating a building’s carbon footprint involves figuring out the weight of each material and then applying the appropriate embodied carbon factor. This will result in a tally of all the carbon emissions associated with a building. By this reckoning, Zero House has an embodied carbon footprint of 6.991 metric tons of CO2-e (which includes carbon dioxide emissions and other types of emissions expressed as units of CO2) emissions for this 1,000 square foot (92.9 m2) building. This is about 75.25 kg of emissions per square meter. This compares very favourably with the same house built to typical code standards, which would emit 134.8 kg per square meter. That’s a 56 percent reduction, which alone would be worthy of notice.

However, there is another side to carbon emissions and buildings. If a building uses plant-based materials in its construction (wood, straw, hemp, cork, bamboo, mycelium and recycled fibres of all kinds), those materials are partially made of carbon that has been taken from atmospheric CO2 and converted by the plant into its cellular makeup. Usually, the carbon in plants is released back to the atmosphere when the plant decomposes (or burns). But if we contain that plant fibre in a building for a long time, we sequester that carbon in the building. It’s the simplest form of carbon capture and storage (CCS); the plants do all the work of pulling CO2 out of the air, and we put them into buildings for a long time.

Zero House uses a wide range of carbon sequestering materials. In fact, the shell of the house only uses three materials that do not sequester carbon. We can tally up the amount of carbon sequestered in materials by calculating the weight of each material, factoring in the average carbon content (the Phyllis database is a good source for this). Most plants contain 40-50% carbon by weight. When this carbon is released to the atmosphere as CO2, two oxygen molecules are added to each carbon molecule, so we multiply the weight of the carbon by 3.67 to find the weight of CO2 that is being sequestered.

As the table shows, the Zero House sequesters a lot of carbon: 32.26 metric tons of CO2 are effectively bundled up in this building! This offsets the embodied carbon footprint and we end up with a net sequestration of 25.26 metric tons. While a lot of this sequestration is in wooden materials, about half of what’s sequestered is in the form of “waste” fibres (straw, recycled wood fiber, recycled drink cartons, recycled newsprint, cork) that would have otherwise cycled directly back into atmospheric CO2.

This approach has great potential to help the building industry fight climate change. If all residential buildings were to take this approach, the 200,000-ish houses we build in Canada every year (at an average size of about 2,200 square feet) we’d be sequestering around 1.1 million metric tons of CO2-e per year. Add other building types (commercial and industrial) into the mix, and the construction industry could lead Canada in carbon sequestration.

With a “negative” carbon footprint from inception, Zero House also takes a zero net energy approach that will ensure that it has a tiny amount of operational carbon footprint over its lifetime. We’ll examine that in our next look at the Zero House goals…